But Will the LT Eventually Replace Them?

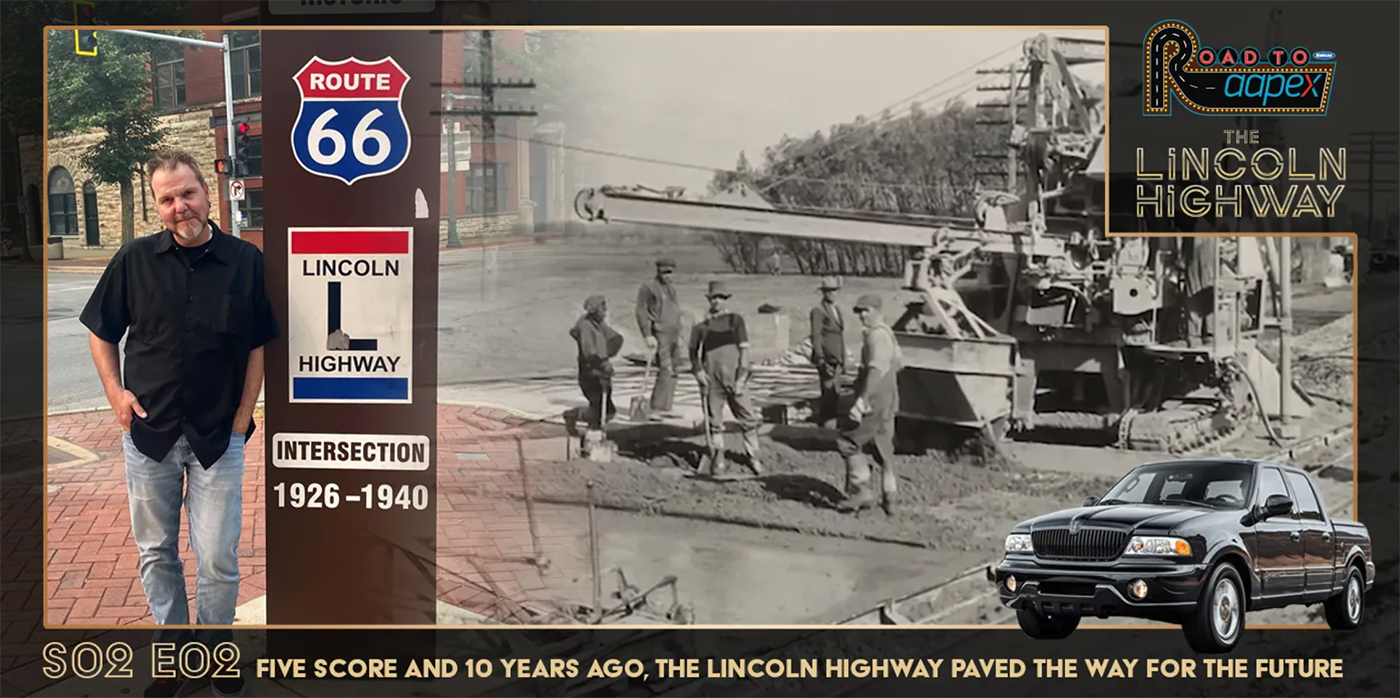

Yes, the title of this article is based on a quote from Ben Stiller’s 2001 comedy film, Zoolander, where Will Ferrell’s character Jacobim Mugatu says the line in reference to Owen Wilson’s character, Hansel. But the quote is certainly fitting when speaking of the LS engine platform. They are hot right now, and have been for quite some time, with seemingly no slowing down in the forecast.

Despite being an almost 25-year-old engine platform – initially released in 1995 – the LS engine remains one of the most used platforms for racing and performance applications, whether it’s street/strip, drag racing, off-road racing or even marine. GM has since followed up the LS engine with the newer LT platform in 2014, but the aftermarket has been hesitant and slow to move away from the LS in favor of the LT for a number of reasons. We’re going to dive into the details of these engines and discuss why they’ve become really, really, really, ridiculously popular (sorry, last Zoolander reference).

The LS History Lesson

The LS-based small block engine is the primary V8 used in General Motors’ line of rear-wheel-drive cars and trucks. Introduced in January 1995, it is a “clean sheet” design with only rod bearings, lifters and bore spacing in common with the longstanding Chevy small block V8 that preceded it. The basic LS variations use cast iron blocks, while performance editions are aluminum with cast iron sleeves/liners.

The LS small block has been manufactured in three generations – III, IV and V – with preceding Generations I and II of modular GM small block engines having been based on the Chevy small block V8 originally released in 1954. GM recycled the “LT” designation beginning with the LS Generation V LT1 in 2014.

There are several performance improvements in the LS family over the previous, classic, small block V8 family. The lower section of the block incorporates deep side skirts, along with 6-bolt cross-bolted main bearing caps. This fully boxes the crankshaft, creating a very strong and rigid structure perfect for hot rodding and high horsepower.

Although it is the same compact physical size as the classic small block V8, this block can accept a 4˝ stroke as an option in its stock form, due to the cam location being elevated slightly compared to previous block designs. Also, the cam bearing journals are larger, to allow for a higher cam-lift profile than was previously possible. The stock aluminum heads can provide a high amount of airflow, which previously could only be found in aftermarket race-performance heads.

The aluminum heads also incorporate steam vents to prevent gas pockets from building up in critical areas, and this is vital in allowing the coolant to manage heat build-up for high-performance applications. Such design features allow for a higher compression ratio with no fear of detonation. Modern fuel-injection techniques eliminate fuel atomization concerns under all conditions, so the LS family uses a dry intake manifold, which removes a common coolant leakage point and allows incoming air to remain cooler for better power production.

Gen III

The Generation III small block V8 replaced the Gen I and Gen II engine families in 2002 and 1995, respectively. Like the previous two generations, the Gen III/IV can be found in many different brands.

The architecture of the LS series makes for an extremely strong engine block with the aluminum engines being nearly as strong as the iron generation I and II engines. The LS engine also used coil-near-plug style ignition to replace the distributor setup of all previous small block-based engines.

The traditional five-bolt pentagonal cylinder head pattern was replaced with a square four-bolt design and flat-top pistons (in the LS1, LS2, LS3, LS6, LS7), while all other variants, including the newer LS9, received a dished piston. The cylinder firing order was changed to 1-8-7-2-6-5-4-3, so the LS series corresponds to the firing pattern of other modern V8 engines.

The first of the Gen IIIs, the LS1 was the originator of the new architecture design that would transform the entire V8 line.

Gen IV

In 2004, Gen III LS engines were superseded by Generation IV. This category of engines has provisions for high-displacement ranges up to 454 cid and power output to 776 hp. Based on the Gen III design, Gen IV was designed with displacement on demand in mind, a technology that allows every other cylinder in the firing order to be deactivated. It can also accommodate variable valve timing.

This family of blocks were the first of the Gen IV small block with the LS2 being the originator of this family and generation. This family of blocks has seen a wide range of applications from performance vehicles to truck usage. The LS2 was introduced as the Corvette’s new base engine for the 2005 model year. It also appeared as the standard powerplant for the 2005–2006 GTO. Other popular Gen IV LS engines include the LS3, LS4, LS7 and LS9.

“It took the best of what we know as far as airflow and valvetrain characteristics from small block engines and aftermarket race stuff and incorporated it in a good beginning platform to start with. To me, that was the contributing factor for the LS being so popular.” – Luke Siebert

Gen V

In 2007, the LS3 would be the final design in the Gen IV small block engine family, and the future designs would be part of the Gen V engine family. The first Gen V LT engine was the LT1, announced in 2012 as the initial powerplant for the redesigned Corvette C7.

All Gen V engines are aluminum blocks with aluminum cylinder heads, and include direct injection, piston cooling jets, active fuel management, a variable displacement oil pump, and continuously variable valve timing. However, they all retain their ancestors’ two-valve pushrod valvetrain.

The 6.2L 376 cid LT1 engine debuted in the 2014 Chevrolet Corvette Stingray and is the first Gen V small block engine. The LT2 engine debuted in the 2020 Corvette Stingray as the successor to the LT1. It was designed specifically with mid-engine placement and dry-sump lubrication in mind.

The LT4 engine builds on the design strengths of the previous LS9 supercharged engine used in the sixth-generation Corvette ZR1 and leverages the technologies introduced on the seventh-generation Corvette Stingray, including direct injection, cylinder deactivation and continuously variable valve timing, to take Corvette performance to an all-new level.

The LT4 engine is based on the same Gen V small block foundation as the Corvette Stingray’s LT1 6.2L naturally aspirated engine, incorporating several unique features designed to support its higher output and the greater cylinder pressures created by forced induction, including: aluminum cylinder heads, lightweight titanium intake valves, forged powder metal steel connecting rods, 10:1 compression ratio, direct injection, forged aluminum pistons, stainless steel exhaust manifolds, aluminum balancer, and standard dry-sump oiling system with a dual-pressure-control oil pump. The engine also uses a 1.7L Eaton TVS Supercharger.

The LT5 engine debuted in the seventh-generation Corvette ZR1 in 2017 and retains the Gen V OHV valvetrain and is topped with a 2.6L Eaton TVS Supercharger and an improved intercooler. It simultaneously couples the standard direct injection system found on Gen V engines with port fuel injection.

LS vs. LT

Simply put, the LT is just the next step in progression from the LS engine family. The two engine platforms are really similar in design, especially in the short block. Due to these similarities, connecting rods, pistons and even crankshafts are very similar.

“The crankshafts are so close you can actually lay them in each of the LS or LT blocks,” says Kyle Thompson, owner of Thompson Motorsports in Nevada, TX. “However, they won’t work in each other’s blocks, but dimensionally they’re almost identical. Once you get into the heads, the LT is probably closer to an LS7, they just added the direct injection to it. Valve angles, flow numbers and the general characteristics of the LT heads are similar to the LS7. They have a tighter chamber that allows you to get away with a lot more compression using the same quality fuel, which is a really nice aspect of it.”

If you’re looking to use one engine over the other, the LS is a more simplified version, and it’s still less expensive to build with more parts available for it.

“The LT has more technology to it,” Thompson says. “There’s really no getting around that. It’s got more capability, it just hasn’t produced the extent of its capability yet because the aftermarket has not caught up to it yet. It’s coming quickly though, and I think it’s really going to progress when they release a 6-bolt head, which is the biggest shortcoming of the LT at this time.”

Deciding between building an LS or LT engine, as usual, is customer preference. The simplicity of the LS and the many aftermarket parts makes it an attractive build for many applications. The LT can be built up just as well, but getting similar results takes more time, effort and money.

“You can take an LS, put a Holley on it, use a budget-friendly head and have an easy 1,000 horsepower boost motor,” Thompson says. “With the LT, getting there takes a little bit more. The operating system is more complicated on it. The tuning and operation of it is more complicated using the factory GM components than you’re seeing with the LS stuff.”

The folks at Katech Engines in Clinton Twp., MI, have been on the leading edge of LT engine development, and Jason Harding, Katech’s director of aftermarket operations, agrees that tuning the LT keeps some people away.

“In terms of the LT’s mechanicals, there’s nothing that crazy about it versus an LS engine,” Harding says. “A lot of times it’s the tuning that gets people because it’s more complex with direct injection. I think that’s maybe weeding out some of the smaller places not capable or afraid of advancing. The tuning is far more complex and it’s only going to get even more complicated.”

Despite that complexity, don’t be fooled, the LT engine is well-suited for performance. In fact, Luke Siebert, owner of Siebert Performance in Topeka, KS says there’s no better market for the engine.

“We do a good bit of power adder street engines and if you’re going to see the LT coming to any market, it’s going to definitely come into the high-performance street/strip market first,” Siebert says. “Like the LS, the LT is definitely a very strong, good platform that you can make a lot of power with.”

The leading problem for engine builders and the LT has been the lack of aftermarket support surrounding blocks and heads. The other engine internals haven’t been the issue. In addition, the LT’s direct injection will take some getting used to.

“The direct injection is a great deal, but in the performance aftermarket that will be the limiting factor because I don’t know that it’s going to be the right option for every facet of the motorsport market,” Siebert says. “I just don’t think it’s going to be as wide ranging. As with the LS, you still have a couple options there – carbureted or standard port-style fuel injection – and those are going to work across the board.

“Like a lot of platforms, the LT engines have a couple quirks that make you wonder what the GM engineers were thinking when they designed it. Or you’ll look at it and go, okay, I see where they’re going with this, but for the performance world it needs to be changed. That’s where I think the aftermarket can open it up.”

Performance Capabilities

Due to the similarities between LS and LT engines, performance capabilities are very similar as well, but how you get there is currently vastly different.

“The LT is capable of the same kind of power as the LS, it’s just able to do it in a more clean manner,” Thompson says. “With an LS, you’re looking at a motor that’s a really solid platform from 500 hp to almost 3,000 hp, depending on budget. The LS are not big motors, so it is still a lot of strain on them to get near 3,000 hp.

“The LT is pretty limited once you get over 1,200 horsepower just because of the lack of 6-bolt set up. Now, there’s a lot of builds out there making more than that horsepower, but when you start getting into the head clamping force issues, that’s more difficult to overcome without having thicker deck, 6-bolt castings available.”

In spite of what some builders have struggled with in regards to the LT, Katech Engines has been one of the few shops pushing the limits of the LT platform and has seen some great results.

“We hit the ground running with the LT1 when it came out,” Harding says. “We did a lot of N/A 427 testing and sleeved LT1 blocks to make our 4.125˝ bore x 4˝ stroke 427. The LT platform has performed very well. For example, our 427 LT1 made 700 horsepower. When we achieved that, we were the highest horsepower LT engine at the time. There’s been a few others who have gone higher, and since then we came back with another round of LT 427 testing featuring our new LTK heads, higher compression and a better intake manifold, and it allows us to achieve 806 horsepower naturally aspirated. We’re once again the highest horsepower LT 427.

“On the supercharged front, we’ve done a lot of C7 Z06 stuff. When the ZR1 came out, we knew the LT5 was going to be a pretty hot engine, so we spent a lot of time on the dyno with the LT5. We have found fuel limitations, so we spent a lot of time developing our XDI fuel system to be able to supply e85 that these boosted engines absolutely love and supply the volume necessary to make over 1,000 horsepower. We made 1,486 hp with a twin turbo on an LT5 before we bent a connecting rod in a stock bottom end.”

Where the LT hits its limits around 1,400-1,500 horsepower, the LS engine has the support necessary to go well beyond those power levels.

“We build quite a wide range of LS engines – anything from mild – just over stock – to turbocharged LS Next block engines that are making well over 1,500 hp to the tires,” Siebert says. “Our biggest market is the higher compression, naturally aspirated LS engines for bracket racing. For our 402 LS motor, we can go quite a ways with it using some very basic components. We’ll start with a brand new GM 6.0L block, a K1 Technologies 4˝ crank, H-beam rods, Wiseco domed pistons, GM Performance LS3 cylinder heads with their port work and their valves, some Brian Tooley dual springs, and a carburetor on gas, and we can make just over 700 horsepower with a hydraulic roller and 13:1 compression. Nothing exotic for the heads or block, but it far surpasses what you can do with a small block with similar parts. You’d have to try pretty hard and buy some nice stuff to make 700 horsepower with a small block.

“Going to the LT, based on the structural integrity of them and sighting the ones that we’ve done, I would have no problem taking a stock block, a stock crankshaft with upgraded rods, pistons and a power adder and taking one to 1,300 hp, maybe even 1,500 hp. I think 1,500 hp would be pushing it pretty good because of the head gasket capability, but going well north of 1,000 horsepower is no problem.”

Popularity

We know performance capability is in the DNA of both the LS and LT platforms, but what else is aiding in the huge popularity of LS engines over their younger brother, the LT engine? To start, engine builders’ familiarity with the LS.

“A lot of people still think of LS engines as something new,” Siebert says. “They’re not anything new. They’ve been around for 25 years at this point. In this part of the country (Kansas), the LS engines are still far more popular. It’s my personal feeling that the LT won’t ever surpass the popularity of the LS engine. Mainly because the LS engine is still a little bit closer to home for people.

“I think the LS is still close enough to what we were working with before as far as a small block Chevy, small block Ford or even a big block Chevy. It is close enough and familiar enough to where it is just a new take on it. It took the best of what we know as far as airflow and valvetrain characteristics from small block engines and aftermarket race stuff and incorporated it in a good beginning platform to start with. To me, that was the contributing factor for the LS being so popular.”

The other reason has been the huge aftermarket support and the amount of cars, F bodies, GTOs, Corvettes and trucks the LS platform was in.

“The LS has such a huge aftermarket now and you can do so much with them,” Siebert says. “I think it would take quite a while for the LT to get there. The biggest benefit of the LT is the direct injection, and in my market, I don’t see it being utilized anytime soon.”

While the direct injection might not work for every application, there are some who do see the LT engine gaining popularity in the very near future.

“I think the LT is going to start to overcome the LS as aftermarket products get released, but at the moment, the LS is definitely still pulling hard on the LT as far as popularity,” Thompson says. “I think it’s going to happen really quickly because everything is moving that direction. We just need a streamlined way to use a wide variety of aftermarket operating systems and a 6-bolt head. I would not be surprised to see both of those remedied in 2020, and once those are remedied, I think it will very quickly take over the market.”

Those remedies will certainly help the LT gain more traction in the market, but it is still more expensive to build than an LS and there is an abundance of stock LS blocks available for rebuilds, where that’s not the case for the LT.

“We do plenty of aftermarket block LS engines, but the far majority of them are stock blocks,” Siebert says. “With an LS engine you can still go find another short block or go to the junkyard. On the LT platform, it’s not that easy and it’s also much more expensive. That’s what I see as some of the differences and why the LS got to be so popular and why it remains still very popular.”

The bottom line for the LT’s future lies in where GM decides to take the platform. Any sort of variances GM has will make a difference.

“It’s a very good engine,” Siebert says. “There’s nothing wrong with it. I just need to start seeing some more aftermarket pieces as far as cylinder heads and things of that nature coming out. LTs haven’t been around long enough for that to happen. It’ll get there for sure. It just takes time.”

For now, the LS reigns supreme. EB