Opening the car hood presents an incredible array of mechanical parts, the most important being the engine. Modern day vehicles depend on heat engines to work, which converts energy from the combustion of fuel to mechanical energy/torque. This torque is then applied to the wheels, allowing for the locomotion of the vehicle. Internal Combustion (IC) engines are the most common form of heat engines used in many vehicles, boats, ships, airplanes, and trains.

Traditional IC engines combust a fuel-air mixture to release heat, which increases the pressure in the combustion chamber, pushing a piston down. The movement of the piston is connected to a crankshaft, which provides torque to the rest of the powertrain. In a combustion reaction, the expected products are carbon dioxide and water vapor. However, in reality the exhaust gas also includes harmful pollutants such as nitrogen oxides (NOx), unburnt hydrocarbons (HC), carbon monoxide (CO) and particulate matter such as soot (PM).

The NOx is caused from the disassociation of nitrogen and oxygen due to heat in the combustion chamber. Also, since the air and fuel mixture are not 100% homogenous, a part of the fuel will not burn, creating the compounds mentioned above. While environmental concerns continue to rise, many IC engines need to be reconsidered and upgraded with the environment in mind.

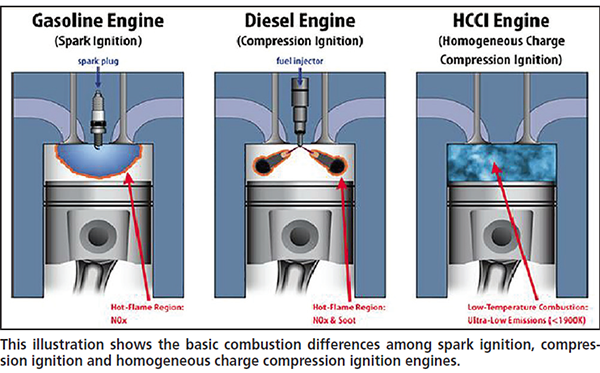

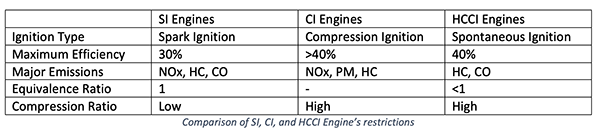

The most common types of IC engines are the Spark Ignition (SI) engine and the Compression Ignition (CI) engine. These IC engines are generally four stroke engines, which allow them to cycle through the five necessary functions: intake, compression, ignition, combustion, and exhaust. With the SI engine, the fuel enters the engine with air during the intake process. It is then compressed, combusted and expanded prior to it being exhausted out. With the CI engine, only air enters during the intake process, which is then compressed. Once the combustion chamber is at a high pressure and temperature, the fuel is injected into the chamber, where it promptly combusts. The subsequent fuel-air mixture then expands and exhausts out.

A lesser-known alternative is the Homogenous Charge Compression Ignition (HCCI) engine. The HCCI engine needs neither a spark plug from the SI engine nor does it need an injector from the CI engine for the combustion reaction. Its combustion is spontaneous with its homogenous mixture of air and fuel being compressed. The HCCI engine synergizes the advantageous properties of both the SI and CI engines. While it has its benefits, though, it has been out of the spotlight for quite a while due to its downsides. This article will discuss the potential of the HCCI engine as well as promising trends that have stemmed from the engine.

Onishi et al., the inventors of the HCCI engine, sought to develop an improved engine combustion process that reduces engine emissions while improving engine efficiency. They introduced the HCCI engine as a solution. As described from its name, HCCI engines rely on the compression of its homogenous fuel-air mixture until it self-combusts. It consists of a diluted and premixed charge consisting of fuel and oxygen that has many different ignition sites throughout the combustion chamber, as compared to the single ignition site of the CI and SI engines.

In a four-stroke engine, this combustion process will occur in the third stroke, just like the other ICEs. Due to having multiple ignition zones, it eliminates the high temperature zones within the engine, therefore being able to operate under a low enough temperature that does not allow the formation of soot and much of the formation of NOx, which is a large problem for the CI engine as well as for the SI engine with the formation of NOx.

Given the potential benefits and novelty of HCCI engines, companies, research labs and universities have been investigating it for over two decades. The topic became popular in approximately 2006 and has remained a popular research topic. Much of the research focuses on how to maximize the benefits while handling its challenges.

Benefits of the HCCI Engine

HCCI engines have been shown to reduce emissions, especially effective in reducing NOx emissions by 90-98% in comparison to conventional diesel combustions. NOx forms when fuel is burned at high temperatures, typically at temperatures higher than 2200 K. The combustion in HCCI engines occur in temperatures significantly below that in the SI and CI engines, therefore inhibiting the formation of NOx. As mentioned before, due to the many ignition sites in the cylinder, HCCI engines eliminate high temperature zones within the combustion process. This is especially important in the consideration of which ignition combustion engine to use as both SI and CI engines produce large amounts of NOx emissions, while the NOx emission produced from HCCI engine are miniscule and can even be accounted as negligible. In addition, due to the homogenous nature of the mixture in HCCI engines, there is little excess oxygen to react with the nitrogen during the combustion to produce large amounts of NOx emissions.

The amount of particulate matter is also decreased with the use of HCCI engines. Since PM are formed in regions with fuel rich mixtures and high equivalence ratios, they are largely apparent in CI engines. Equivalence ratio is defined by the actual ratio of the fuel/air ratio to the stoichiometric ratio of the fuel/air. When the equivalence ratio is higher than 1, there is not enough air to complete combustion, leaving behind soot in the process. When the equivalence ratio is less than one, there is excess air.

Since the fuel and air is not mixed homogenously in the CI engine, the combustion produces large amounts of soot as there are fuel dense pockets within the cylinder when ignited. HCCI engines combat this by having a homogenized lean mixture, lowering the equivalence ratios, and having a lower operating temperature, therefore heavily decreasing the production of soot. Generally, NOx forms with low equivalence ratios, and high temperature and soot forms with high equivalence ratios and moderate temperature.

Efficiency of the HCCI is also improved in comparison to the SI engine and as high as that in the CI engine. They both boast maximum efficiencies of 40 percent, being one of the higher that is available in the industry. Since HCCI engines are very fuel lean as well as having a higher compression ratio equivalent to that of diesel, it has a very high efficiency. With high compression ratios you get faster ignition and the ability to extract more energy from the combustion process in comparison to a lower compression ratio.

In addition, the combustion duration for the HCCI engine is significantly shorter than the combustion in CI and SI engines, again demonstrating its high efficiency, but might also demonstrate a limitation in engine load. This is due to the lean homogenous mixture, auto-igniting at multiple areas as well as its ability to operate with diesel-like compression ratios, allowing a short combustion duration.

Disadvantages of the HCCI Engine

As mentioned above, the temperature in the HCCI engine is significantly lower than the operating temperatures in the SI and CI engines, resulting in an incomplete burning of fuel, leading to higher amounts of hydrocarbon and carbon monoxide emissions. Although the combustion itself is incredibly efficient and effective in transferring the heat content of the fuel into usable heat, it does lose out on having as high of an efficiency as CI engines due to a small efficiency loss from unburnt fuel. The mixture needs a consistently high temperature to fully produce its expected products, which the HCCI engine does not have due to its low operating temperature, so it leaves behind toxic byproducts, especially carbon monoxide.

In a combustion reaction, the expected products contain carbon dioxide, water and energy. However, complete reactions for the conversion from CO to CO2 requires stable temperatures above 1500 K, explaining why the combustion results in excess carbon monoxide byproducts. Likewise, the presence of hydrocarbons and other intermediates in the exhaust of HCCI engines is due to the incomplete combustion of the fuel. These toxic compounds will leave the system and subsequently pollute the atmosphere through the exhaust of the engine.

In addition, unlike SI engines, which initiate combustion with a spark and CI engines, which initiate with insertion of fuel, the start of the combustion process in HCCI engines cannot be controlled due to the spontaneous nature of the engine. The autoignition event is based on a number of factors, including the residuals from the previous cycles. As such, there is the potential for significant cycle-to-cycle variability. If the ignition timing is off, it may overheat and may even cause engine damage. As a result of these factors, not much attention has been attributed to HCCI engines due to its incredibly impractical and situational design.

Trends and Possible Improvements for HCCI Engines

Extensions of the HCCI engine have been created as attempts to solve the problems that come with the engine. Combinations between engines and combustion strategies may assist in employing the benefits of both engines. For example, Premixed Charged Compression Ignition (PCCI) tries to use the benefits of the HCCI engine – lower NOx and PM production as well as having high efficiency – but also gaining control over the combustion phasing from the SI engine. In a PCCI combustion, most of a partially homogenous fuel-air mixture burns in a premixed combustion phase, reducing NOx and soot emissions. PCCI combustion then has fuel injected into the combustion chamber in one of three ways – port fuel injection, early direct injection, or late direct injection.

PCCI engines can get its desired ignition delay through factors such as the use of the exhaust gas recirculation (EGR) and reduced compression ratio. As a result, there will be lower peak temperatures and lower peak equivalence ratios, therefore combatting the formation of NOx and PM as well as gaining control over its combustion timing.

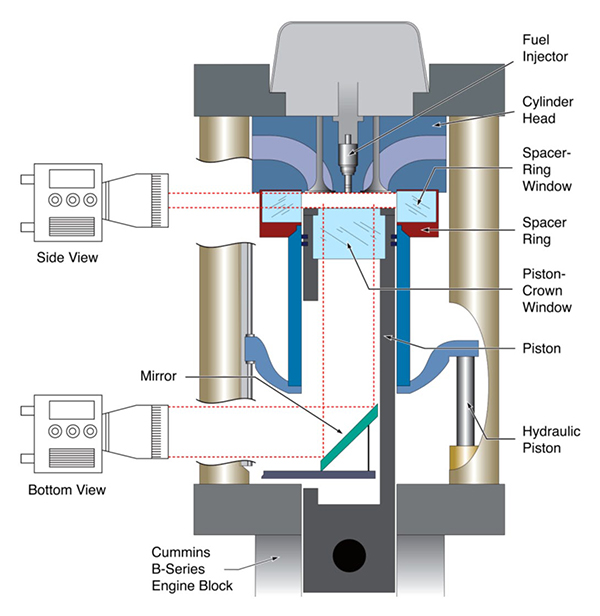

Catalysts are also incredibly helpful in the field of engines. They assist in reducing the harmful emissions contained in exhaust fumes. In a study done by Zeng and Xie, the pair coated the piston crown from an HCCI engine in a platinum catalyst and recorded its effect on the exhaust emissions. They concluded that unburnt HC emissions were reduced by 15% with a full coat of platinum on the piston crown, and a 20% reduction with a partial coat of platinum. Also, the exhaust CO emissions were reduced by 13% with a full coat and 7% with a partial coat, showing how imperative it is to use a catalyst for less toxic exhaust emissions.

Additionally, different types of fuels can also be utilized. Biofuels, being environmentally friendly and a promising substitute for conventional fuel, can also promote strong changes benefitting ICEs. For example, biofuels containing oxygen enhance the combustion process in HCCI engines while also bringing improvements such as lower equivalence ratios between fuel and air, lower operating temperatures and reducing the CO and hydrocarbon emissions. Biodiesel such as liquid petroleum gas, hydrogen and methane used in gasoline engines have a general reduction of CO and HC emissions by 20-30% and 30-35% respectively. So, a move toward a cleaner fuel will also benefit in cleaner engine exhausts and emissions.

Future of HCCI Engines

HCCI engines are an incredibly promising engine, with many benefits including its decrease in emissions as well as an increased efficiency. While it does have its downsides such higher emissions of HC and CO as well as having an uncontrolled combustion process, advances have been made to improve the design.

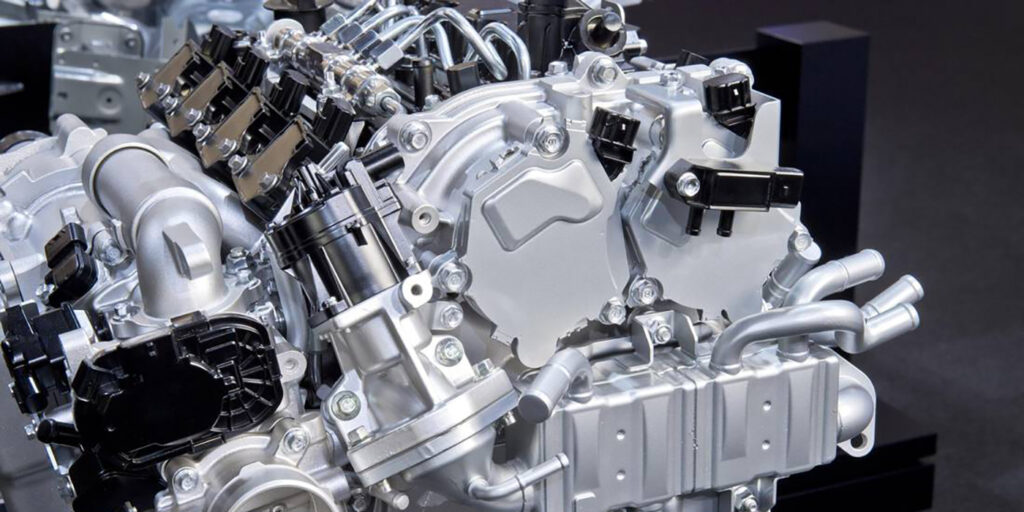

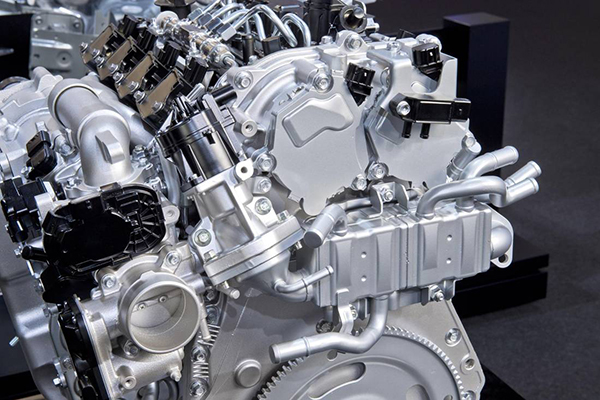

As HCCI engines continue to develop, its applications are continuously being implemented. No cars have utilized HCCI engines as it is a situational and often impractical engine until last year when Mazda Motor Corporation promoted its new cars with the SKYACTIV-X engine, which utilizes SPCCI (spark-controlled compression ignition) by combining the lean fuel to air mix from the HCCI engine to the spark ignition from the SI engine. It compresses the mixture at a much higher ratio than it would in a regular SI engine and ignites only a small dense amount of fuel-air mix in the cylinder. As a result, the temperature and pressure will be raised, which will cause a spontaneous reaction for the rest of the mixture.

Mazda released cars with this engine earlier this year, bringing great results as a powerful and fuel-efficient engine. Before electric cars completely become the staple choice, HCCI stands as a strong contender against the more conventional combustion engines, given that more research and ironing out of issues are to be done.

About the Authors:

Dr. Raj Shah is a Director at Koehler Instrument Company in New York, where he has worked for the last 27 years.

Blerim Gashi and Kyle Lin are Chemical Engineer students from SUNY Stony Brook University, where Dr’s. Shah and Mittal are on the external advisory board of directors.

Dr. Vikram Mittal is an Assistant Professor at the United States Military Academy in the Department of Systems Engineering.