Diesel of the Week is presented by

We see a lot of familiar faces at diesel competition events, mostly because the guys and gals that compete are closely tied to the community and show up at as many events as possible year to year. Because of this, there’s a few big names that have built up a following over the years for their various feats and exploits.

One of those is none other than the Dirty Hooker Diesel team, headed by Tony Burkhard. Tony, with his son and driver Tyler, pulled off a great weekend at the 2022 Ultimate Callout Challenge a few weeks ago. After more than respectable efforts in all three areas – drag racing, dyno day and sled pulling – the team stood upon the podium at the end of the weekend with a solid third-place finish overall, not far behind the likes of second-place Derek Rose and first-place Justin Zeigler.

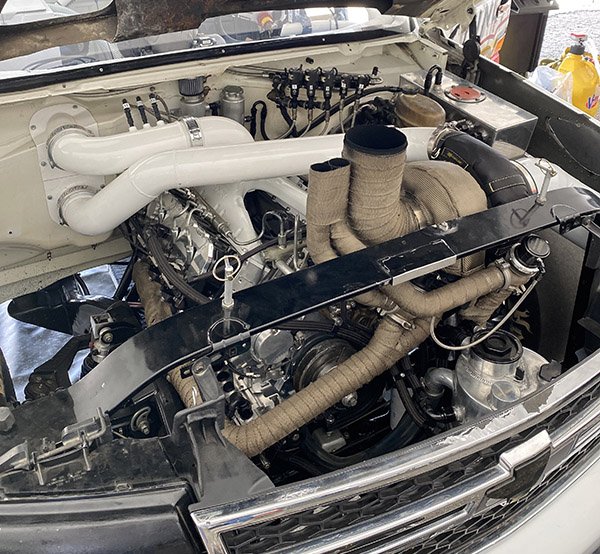

Once again, the team competed with Last Minute Hooker, their ’06 Silverado that’s become rather storied over the years at UCC. Most notably, from its explosion and subsequent fire that occurred on a dyno pull during the 2019 competition because of a loose turbocharger exhaust wheel. Remarkably, the team was able to drop in a new engine and repair the truck enough to compete in the sled-pulling event the next day.

This year, there weren’t any major mishaps, and the truck performed admirably. Like before, the team is running a billet-aluminum block from LSM Systems Engineering. The 460 cid Duramax engine has gone largely unchanged from years past, but still boasts several key parts that keep it running smoothly. On dyno day, the truck was able to produce 2,486.9 horsepower for a 5th place finish.

Wagler aluminum cylinder heads with larger valves are mated to the block, and a Wagler camshaft controls the valvetrain. The heads and block were both fire-ringed to support the ~2,500 horsepower range that the truck usually sits at. For the rotating assembly, Burkhard went with a Winberg crankshaft anchored in place by ARP main caps and main studs, R&R aluminum connecting rods, and Diamond Racing pistons.

The real standout of the build is the fuel and air setups, which helped the team run an impressive 4.96-second drag run at 152 mph in the 1/8-mile.

“That last pass at 4.96, we were at 77 lbs. of boost and 330 cubes of fuel,” Burkhard says. “We have five different nitrous jets we can play with and try to get it to come in. You put a big jet in but it hits so hard, so we try to modulate the nitrous solenoids so they ramp in smooth, but it still makes so much horsepower when you introduce nitrous in there.”

On top of the engine is a huge T6 Precision Turbo with a 106mm compressor wheel that’s limited at around 80-psi of boost by dual 45mm Precision wastegates. The turbo is driven by DHD high-flow exhaust manifolds with double stitch titanium manifold blankets and heat wrap to aid efficiency.

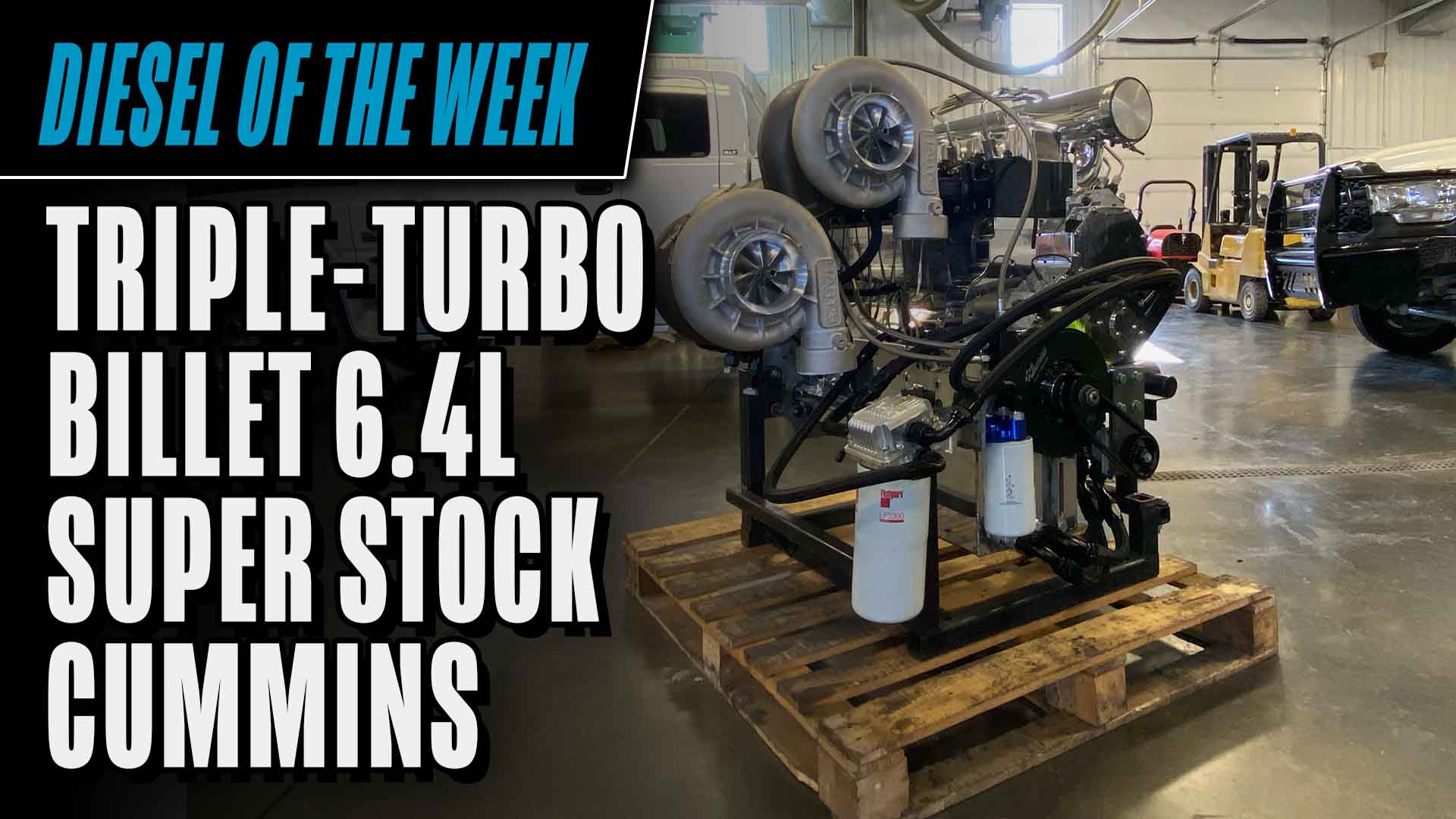

On dyno day, the DHD team switched its single turbo setup for a triple-turbo setup, which had fellow competitors, fans and even the DHD team themselves, anxious to see what numbers it would make.

As for fuel, the team at DHD is rocking an Exergy fuel system consisting of two stroker 14mm CP3 pumps, which deliver fuel to Exergy injectors that are fitted with 400% over nozzles. Inside the cockpit, a Bosch standalone system controls the shifting and nitrous.

“We’ve done a few weight improvements and we have a little work here and there to do to make it a little bit faster. We have plenty on tap, it’s just working on keeping it hooked to the track.”

Like many other teams competing at UCC, Tony and the crew at DHD took advantage of the new two-truck rule for this year’s competition. All competitors were able to bring a second truck specifically for the sled-pulling event.

“Cheap Hooker” is now the team’s go-to sled truck. Aside from having a filled, sleeved and deck-plated factory OEM block and factory oil pump, the truck is very similar to Last Minute Hooker. Wagler heads and intake, an Exergy fuel system, and 400% injectors all appear on the engine.

This is the first time the team has put nitrous on their pulling truck, and 1,900 horsepower allowed them a nice sixth-place finish with a pull of 281.6 ft. The effort got them third overall, and the Dirty Hooker Diesel team will be back looking to improve even more.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].