Diesel of the Week is presented by

Engine building and diesel performance in general is not for the faint of heart. Any number of things can go wrong with an expensive build leading to partial or complete failure. Running down the drag strip even once is super stressful on the engine under these extreme loads, and it isn’t uncommon for parts to quickly wear out or break completely.

That means reworking and rebuilding engines for competition events is typical, and oftentimes a full year between annual events still isn’t enough time to get builds in working order. Unfortunately, that doesn’t bode well for us as we’re always pumped to see a badass truck run down the drag strip, but nonetheless we’re happy to see a great engine build up close.

That was the case this year at the Ultimate Callout Challenge at Lucas Oil Raceway. Early on in the weekend we stopped by the Maverick Diesel tent to see what the guys over at the Southern Illinois-based shop had going on. Maverick Diesel offers custom tuning, performance parts and upgrades, fabrication work and engine assembly; the shop was opened in 2016 by owner Paul Cato.

Paul graciously offered to show us a truck and engine setup they’ve had for a few years, which had recently gone through a refresh.

“This engine isn’t new, and we’ve been running it since around 2021,” Cato told us. “Last year, we started to make some passes with it and ended up having a tappet failure that got into the actual bore of the block, so we basically took last year off and did a whole revamp and redid everything.”

The team at Maverick went from a stock computer to a MoTec system, and part of the reason for bringing the truck to UCC was having the S&S Diesel Motorsport team tune the new setup. Once they got back to Illinois, the following week was all about testing it.

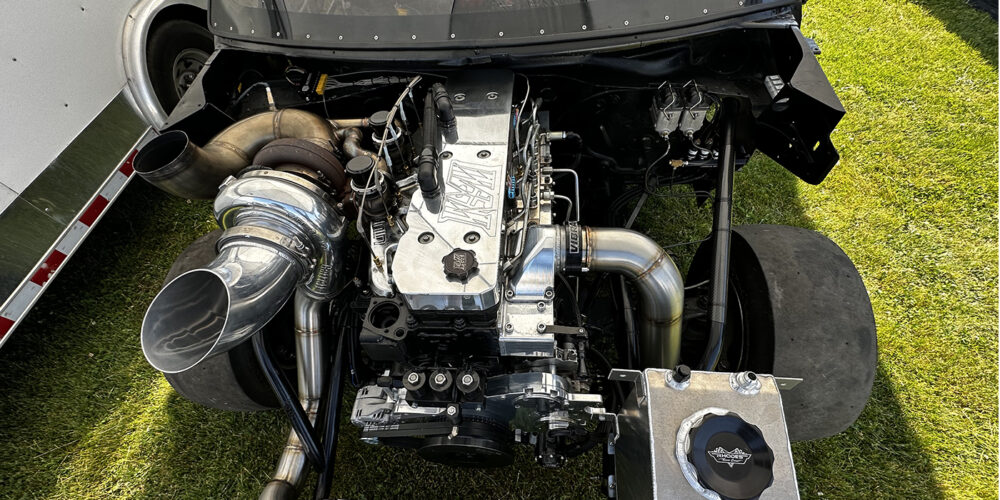

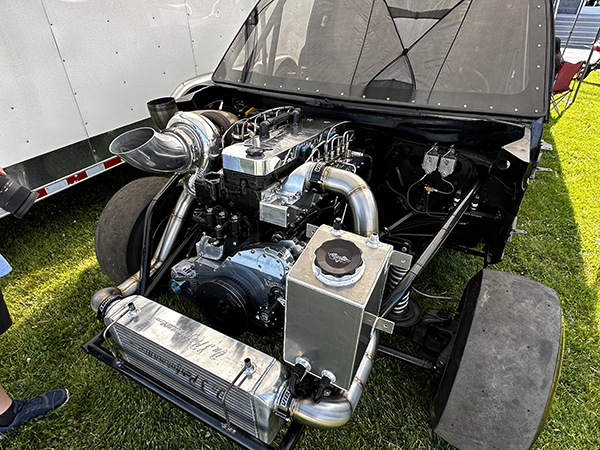

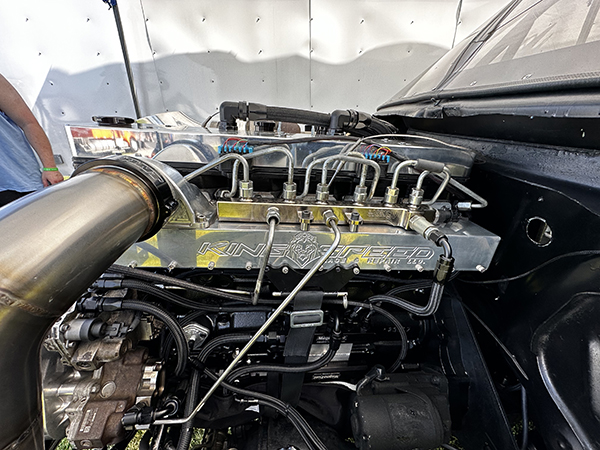

As for the engine itself, it’s a 6.7L Cummins with a Wagler deck plate set up. The cylinder head also came from Wagler.

“We have a 14mm Exergy race pump and a stock pump to support it, then it’s got an 88mm GT55 turbo. We originally had an intercooler with water injection – that was a bit cumbersome, so we went back to air-to-air. We have three stages of nitrous, it’s called the Tripler from Hammertech Racecars. Basically, its three lightning .375 solenoids on his distribution block, and then we’ve got some really big jets we run with lines down to each nozzle.”

Dual wastegates keep the ~115 lbs. of boost under control, more depending on how hard the team is pushing the truck. Huge 500% over Exergy injectors make sure the engine gets a healthy supply of fuel.

Again, it’s been rebuilt multiple times since the initial build, all thanks to LinCo Diesel Performance. After the tappet failure, the team at LinCo bored and sleeved the block back to factory size.

“He’s fixed the crank for us once after we spun a rod bearing, and he’s gone through this cylinder head a couple times as we’ve been pretty hard on it,” Cato says.

The engine isn’t the only interesting part of Cato’s race truck, however. Interestingly enough, he installed a power steering pump off a 2008 Mini Cooper. In the case of blowing up the engine (which Cato admits they often do), he simply flips a switch that fires it on and then the truck still has power steering when the team goes to tow it home.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].