Engine of the Week is presented by

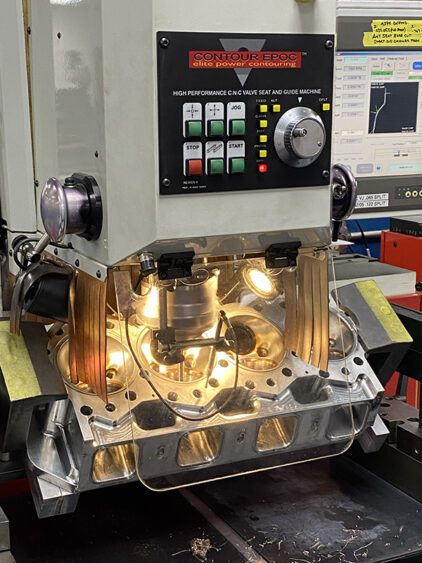

There was plenty to look at when we visited Pro Motor Engines in Mooresville, NC this year. After all, the shop has been around for decades, and had a rich history in NASCAR for many years. Today, Pro Motor Engines (PME) has over 21,000 sq.-ft. of space, 15 employees, and a full machine shop filled with lathes, mills, balancers, surfacers, line bores, hones, seat and guide machines, and CNCs. When we got a tour from shop owner Dennis Borem, it was evident that Pro Motor Engines still does excellent work across a number of race and performance engine applications.

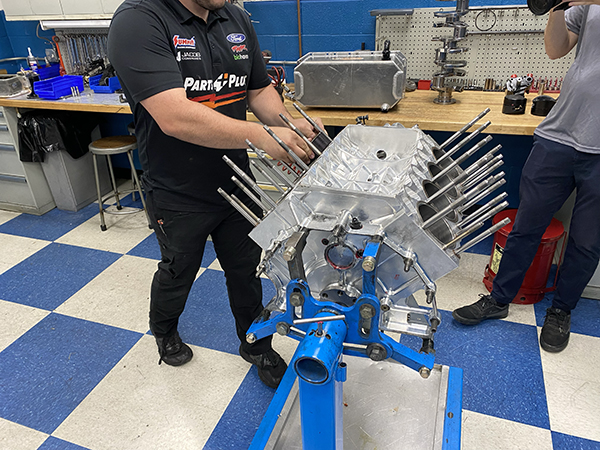

On one of the shop’s two engine dynos was a TA2 LS3 engine, which we featured earlier this year as an Engine of the Week, but around the corner in its own assembly room area was one of Clay Millican’s Top Fuel Hemi engines in for machine work. Obviously, the engine caught our eye, and a member of Clay’s team was there to assist with the reassembly, and even crew chief Jim Oberhofer was on hand to see how things were going. Dennis was able to give us the rundown on the Top Fuel Hemi engine.

“Between this Top Fuel Hemi engine and the TA2 LS, you couldn’t get further polar opposites than these two builds,” says Dennis Borem. “This Hemi makes lots of horsepower and has much different demands.”

How does an engine shop with NASCAR history land a Top Fuel drag racing team’s engine program? Well, Rick Ware in short. As Dennis told us, Rick has a background in stock car racing and road racing, and PME had done the engines for Rick for many years. Rick talked about wanting to get into drag racing and specifically a fuel team.

“The last couple of years we talked and when he decided he was going to go forward, we sat down and we talked about basically giving him support,” Borem says. “Between races, the engines come here and I guess you could say we do some of the heavy maintenance. After these things run X number of runs, the main lines get all out of whack from making in excess of 10,000-12,000 horsepower.

“Basically every run they come apart at the track. You go out there and do your burnout and run hopefully 3.7 seconds and you come back and tear it apart, pull the pistons out of it, check the bearings, and maybe put a sleeve or two in it. They have a mountain of cylinder heads that are in their cabinets, so at the track they’re constantly changing cylinder heads and working on them at the track.

“When they come here, it’s heavy maintenance. We’ll check the cam line, the main line at different intervals, the registers on the sleeves, we’ll pull the sleeves out and send them over to the CNC shop and check everything out and re-machine the engine itself.”

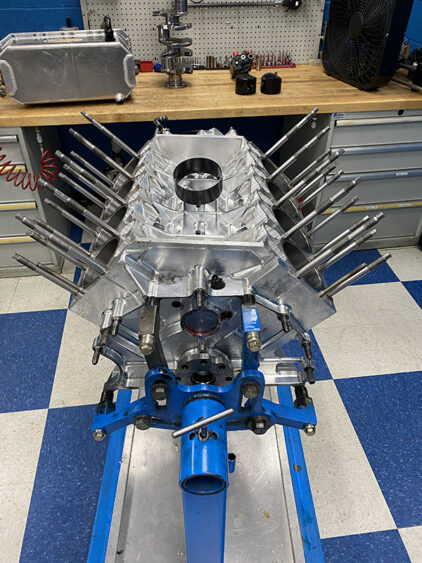

The engine used by Top Fuel teams is loosely based on the 426 Hemi. The NHRA rules dictate that it can be no more than 500 cubic inches, and camshafts can only be as big as 54mm, but aside from that, teams can generally build the engine how they want and use whatever components they want.

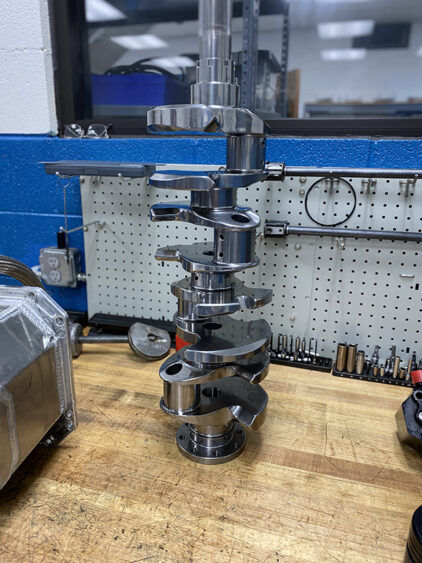

“There’s a few different companies that make these billet blocks,” he says. “For crankshafts, we’re typically using a Winberg, Bryant or Callies billet crank, and these cranks have a life. You might put a crank in and get three or four runs out of it and it comes back for service and it’s got a big crack in it, or you might get nine or 10 runs out of it. All the parts in these engines are very consumable. You’re not making it too long on the same components.”

For those reasons, Top Fuel teams like Clay Millican’s will keep track of the various engine parts and note how many runs a certain component has on it, so they don’t risk catastrophic failure on the track.

“For connecting rods in these engines, Alan Johnson, Schumacher and Bill Miller are the primary manufacturers. Pistons are either Diamond or CP-Carrillo. These pistons are very consumable. For cylinder heads, those are billet and come from Alan Johnson as well. For the valvetrain, we use Victory valves and Xceldyne valve springs.”

When it comes to the more expensive components of these engines, like the billet blocks and heads, it’s on folks like PME to keep those in service for as long as possible via rewelding, resurfacing and other machine work.

“You’ll torch a gasket and it’ll usually blow it out,” Borem says. “If it’s not bad enough, we can bring it back here, pull the sleeves out, weld the deck, prep it, weld it, recut the counter bore and bring it back. However, at some point, you don’t bring it back. The mains are really the worst part of these as far as the life of the block from what we see. They really take a beating at some point. You can repair the mains, put sleeves in them and do different things there, but I couldn’t tell you how many runs you can get out of this block. There’s probably blocks that have 50-60 runs on them, but there is a life on these too where it’s just not worth fixing it at some point.”

Due to the extreme conditions these engines are under, they need some equally extreme studs to help hold the engine together. PME uses ARP to get the needed clamping pressure to hold the head down.

“With a lot of things in these, we’re probably asking more than what we should, but that’s where things evolve,” Borem says. “We try to get better and go faster. We try to be an extra set of eyes on these engines, and then at the racetrack, we go and help where we can.”

There’s a lot going on between rounds at a drag race of NHRA Top Fuel caliber. These supercharged, nitro-burning, billet Hemi engines make upwards of 11,000 horsepower. Trying to keep up with that much power certainly takes a team, and PME does the job well for Clay Millican and Rick Ware Racing.

Engine of the Week is sponsored by PennGrade1, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].