Diesel of the Week is presented by

In covering high-performance, purpose-built engines the majority of the time, it’s easy for us at Engine Builder to get caught up in the numbers. Horsepower, torque, displacement, etc… they’re all important, but power isn’t always everything. Sometimes it’s nice to just sit down and appreciate a well put-together engine that knows it’s place and is reliable.

We recently stopped over at R&R Engine and Machine to catch up with good friend and owner Bryan Menke. We’ve been working with him for the better part of a decade, and it’s easy to collaborate on articles and video projects as R&R is located in Akron, OH, just 20 minutes from our headquarters.

R&R was established back in 1966, and nearly 60 years later they’re still putting out quality engine work. They have a full-service parts department, machine shop, engine and truck shop, and a fuel injection/turbocharger shop. Each segment of the business is under the same roof, but they operate almost as separate businesses.

While they work on all kinds of different engine platforms, diesel makes up the bulk of the business. Cummins engine rebuilding is their bread and butter, and industrial brands like Perkins, Kohler, Caterpillar, Kubota, etc. follow suit.

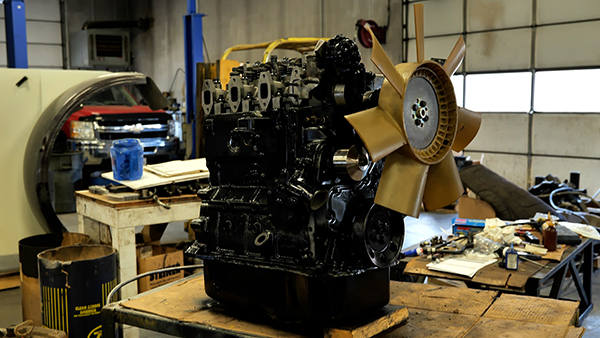

When we stopped by a few weeks ago, Menke had a cleaned up and re-machined 4B Cummins to show us.

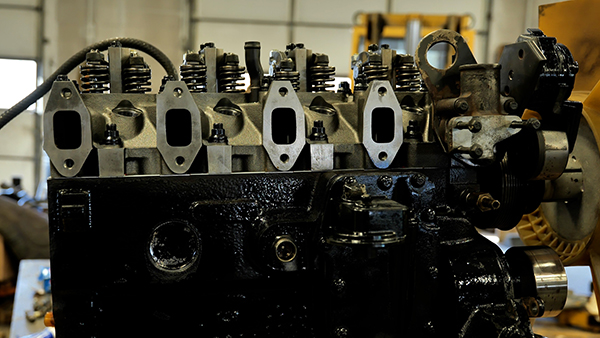

“This particular engine came in recently and it was out of a woodchipper,” Menke says. “It had a lot of blowby and just kind of wore out. Probably some dirt and contamination in there from all the trees.”

The 4B is a stock rebuild, which is the majority of the work R&R gets in. Menke noted that the shop is particularly busy at the moment and this project took around two to three weeks to complete, although this sort of job would normally take a shorter amount of time.

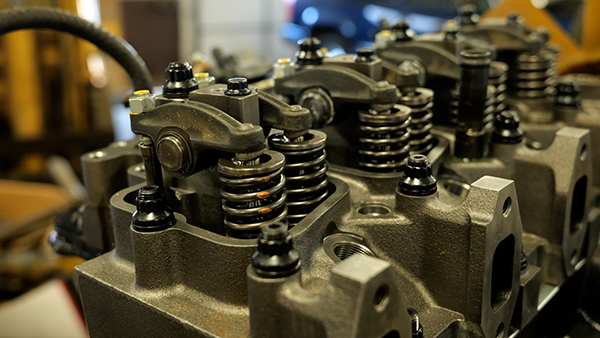

As for work done to the engine, Menke and the team completed necessary machine work and component replacements to get it up and running again. The engine was bored .010″ over and given new pistons, rings and bearings. For the head work, the 4B received a complete valve job with new seats and guides. For the rebuild, Menke utilized AFA and PAI Industries for the replacement parts.

“The 4B can be found in air compressors, stump grinders, chippers, and industrial machines,” he says. “We haven’t put one in an automotive application before, but I’ve seen guys who have. They make between 80-120 horsepower, but they have a lot of torque and they’re good mechanical engines with no electronics.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].