Crack Detection and Repair

When dealing with high-performance engines, it’s imperative to know a thing or two about crack detection!

Crack Detection and Correction

First off, let’s get one thing perfectly clear – there’s no such thing as “flawless.” Like those shocking tabloid photos of that Hollywood actress who gets blindsided beside a bistro, even the most conscientious engine builder sometimes has to deal with surprising surface imperfections. And just as she has paparazzi to expose the damage and

Crack Detection

Take a look in the mirror. Smiling back at you, you’ll notice that row of pearly whites. They probably look pretty good. Maybe a bit stained from coffee or smoking, but overall, they seem to be pretty solid, right? If you’re like many people, the fear sets in as soon as you sit down in

Engine Crack Detection Technology

It doesn’t matter if you’re rebuilding a high mileage engine and reusing salvaged components or using brand new parts right out of the box – any highly stressed component or casting that has to withstand high loads, temperatures and/or pressures should always be inspected to make sure it is free from cracks or other defects

Engine Parts Cracks – How to Fix

One of the essential elements of engine building is making sure heads, blocks, main bearing caps, crankshafts, connecting rods, pistons, cams, timing gears, rocker arms, and flywheels are free from cracks. If you’re doing a complete engine build, checking the intake and exhaust manifolds for cracks is also a good idea – and that includes

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

Tips and Tricks For Quickly and Accurately Detecting Cracks

Dry Method Magnetic Particle Inspection When "Magnafluxing" a casting, never blast with media prior to testing.Blast media peens the surface and can move metal, possibly closing thevery cracks or flaws that you are trying to identify. When very coarsewire brushes are used roughly, they can also mask these areas. Usuallythe casting itself, without cleaning, is

Cracked Cylinder Head Repair

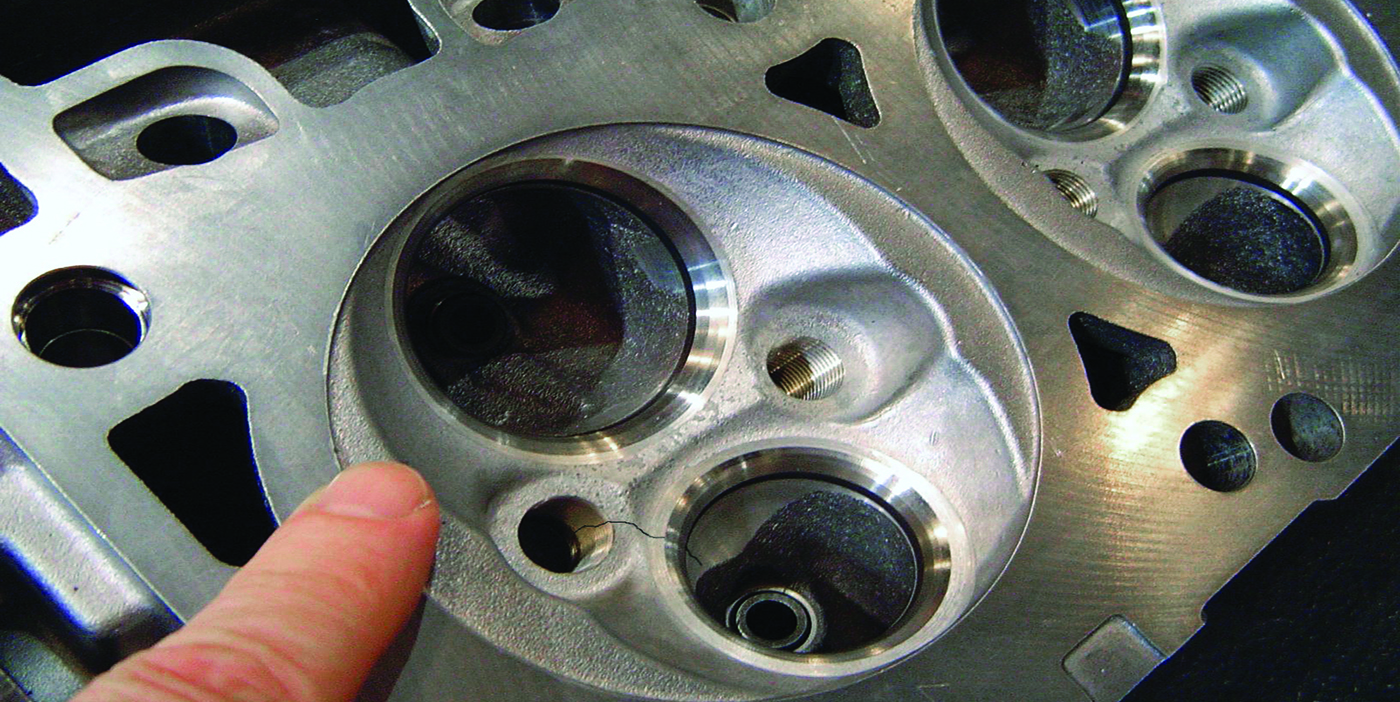

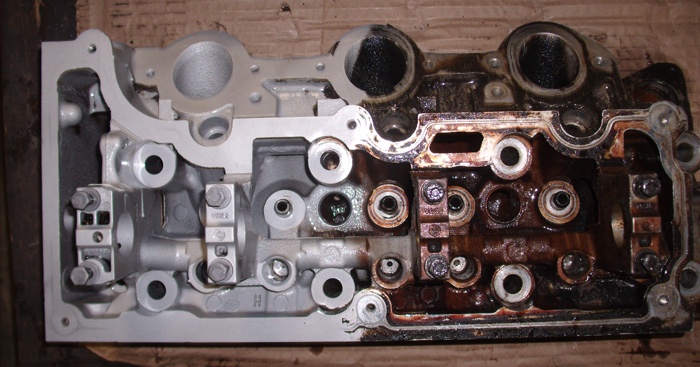

It seems as if many cylinder heads are doomed to crack from the very start because of their lightweight construction and design. Aluminum overhead cam (OHC) heads, in particular, are often found to be warped as well as cracked. But so too are many pushrod cast iron heads. Cracks are often blamed as the cause

Cylinder Head Crack Repairs

It seems as if many cylinder heads are doomed to crack from the very start because of their lightweight construction and design. Aluminum overhead cam (OHC) heads, in particular, are often found to be warped as well as cracked. But so too are many pushrod cast iron heads. One of the causes of cracking in

Safe Cleaning – Are the Concepts Compatible?

The subject of cleaning is never far from the mind of the modern engine builder or machine shop supervisor. Obviously, parts must be as clean as possible so they can be inspected, repaired if possible and reassembled. The subject of SAFE cleaning is a little less definitive, however.

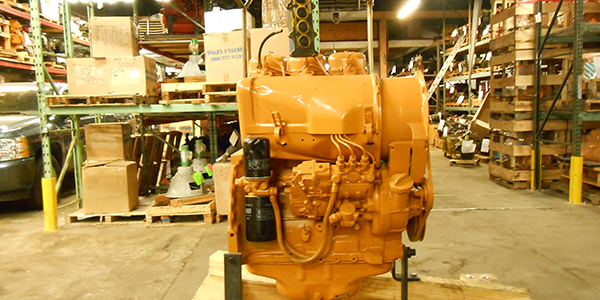

Industrial Engine Rebuild Opportunities

Rebuilding industrial engines is a growing business for many engine builders and shows no signs of slowing down.

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

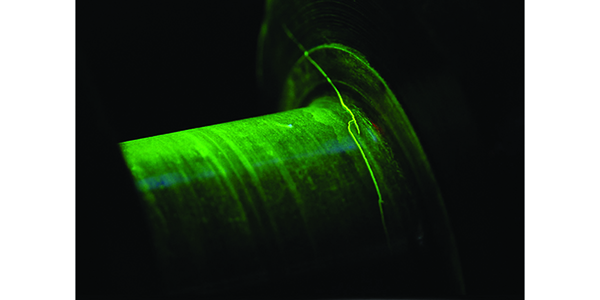

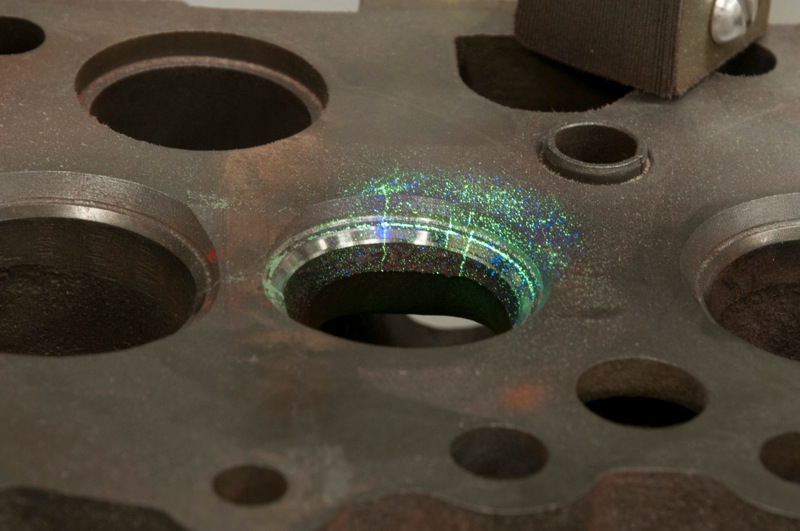

Goodson Tools & Supplies Green Fluorescent Magnetic Powder

Goodson Tools & Supplies for Engine Builders has expanded its options for dry magnetic inspection with the addition of high-visibility green fluorescent magnetic powder. According to Chris Jensen, Goodson Tech Services, “Fluorescent crack detection powder has been around for years but what sets this powder apart from the others is how bright it is, even

Handling Stress Fractures

Salvaging Cracked or Flawed Engine Parts through Detection and Repairs Cracks are often blamed as the cause of a head failure. In many instances, the cracks are not the cause of the failure, but a symptom of another underlying problem such as overheating, detonation or incorrect installation (wrong torque on head bolts, dirty bolt threads,

Pursuing The Small Engine Market

Small engines are everywhere. They power lawn mowers, garden tillers, portable generators, all kinds of pumps, go-carts, ATVs, snowmobiles, motorcycles, forklifts, even refrigerated trailers on reefer trucks. Most of these engines are single-cylinder four-stroke air-cooled motors that range in power from 5 to 15 hp or more. Some have vertical crankshafts and some have horizontal

Keeping Valve Jobs Profitable

Okay, so head work accounts for a large percentage of your business. But is it as profitable as it should be or could be? Do you have a good handle on cylinder head related costs (parts, labor and cleaning)? Are the employees who are doing the head work competent and productive? Is your valve guide

With Today’s Customer

Although you’ll find many definitions, I believe we can all agree that in the mind of your customers, value means getting the most bang for their buck. In the auto service business, there are a number of ways we can create value for our customers in both marketing and sales. Here are some recommendations you

Media and Solutions For Cleaning Engine Parts

One essential aspect of engine building and rebuilding that cannot be avoided is the need for cleaning. Used engine parts have to be cleaned before they can be inspected. Parts that will be reused also have to be cleaned to remove dirt, grease, oil, carbon, rust, scale and other gunk that could contaminate a newly

AERA Announces Engine Rebuilding, Machining Certificate Program

Rather than a test to prove understanding, AERA has chosen to offer a comprehensive online training program leading to diploma-quality certificates in Cylinder Heads and Engine Machining. Technicians who successfully earn either certificate will hold proof that they have an elevated understanding of fundamentals of machining, measuring tools, shop safety, fasteners, engine theory, engine diagnosis,