Understanding How Valve Seats Are Made, How They Work and What Can Happen When They’re Wrong

When it comes to engine cooling, the radiator is kind of a showoff. It sits right up front, catching the best breeze, dominating the conversation. And when it erupts in a cloud of coolant and steam, everyone knows about it. However, the engine valves (particularly the exhaust valves) shouldn’t be overlooked for the role they

How to Create Dollar Bills Out of Four Common Materials

From engine blocks and heads to oil pans and intake manifolds – engine components are common items that require repair, maintenance or replacement in the shop. Whether you’re working on a car, light-duty truck, heavy-duty diesel or a performance racing vehicle, you may frequently encounter a cracked block or cylinder head that requires a welding

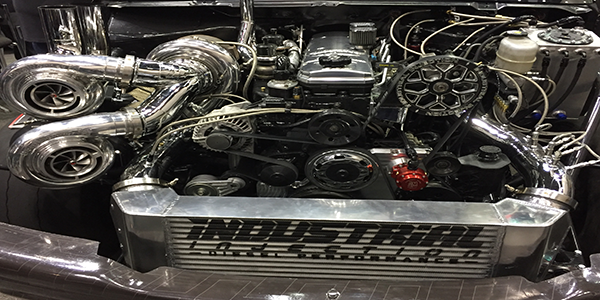

Power Up Those Engines

Selecting the Correct Power Adder for Your Customer There’s no replacement for displacement,” goes the adage. However, this may no longer true considering the kind of horsepower being pumped out of today’s boosted engines. Whether you’re building engines for stock, performance or a diesel application, chances are you’ll be working with an engine that is

Engine Math for Engine Builders

Engine building is a numbers game. Whether you like math or not, you often have to use it when figuring things like engine displacement, airflow, compression ratios and valve lift. Knowing how to calculate these values and how to use the numbers to match pistons, cylinder heads, cams, carburetors and valve train components can help

Cryogenics is Real and It Works – You Just Can’t See It

Cryogenics is a process in which material such as steel and aluminum are exposed to severe cold, down to -320 degrees F to make them more durable and stabilize the metal or aluminum. The closer you get to absolute zero (-459.67 F) the better, but you better not cross that line of -460 F.

We Have Lift Off – Head lift and a look beyond the gasket

In the 1980s, many racers were experimenting with turbochargers on stock engines. Colossal horsepower and torque numbers could be produced for a short period until the engine self-destructed. One of the weakest links they focused on was how to keep the head attached to the block under extreme pressures. Many engine builders experimented with copper

Rocker Arms – Connecting Up Your Valve Train

Understanding how rocker arms work The rocker arms in an engine have one simple but very important function: transferring the opening and closing events from the camshaft to the valves. Well, we all SAY it’s simple, but is it? Questions about what works best are still asked by even the most seasoned professional. With all

Taking Over the World of Engine Building

What you should know if your business is going international Not many businesses are satisfied with simply maintaining a local clientele. Just as customers typically want bigger and bigger engines, engine shops are looking to grow their business reach outside their town, city or state. In some cases, engine shops reach an international clientele, making

What Your Diesel Customers are Asking About FA-4 Engine Oil

The ROI benefits may outweigh the maintenance challenges With a year of the new American Petroleum Institute (API) CK-4 and FA-4 oil categories under the industry’s belt, many of your diesel customers, especially fleets, have likely switched over to the CK-4 formulation, as that was the engine OEM-approved backward compatible formula. The transition to FA-4

Ford FE Stroker Build

Guardian of the Galaxie How Ford’s FE Engine Rose from the Ashes of Disaster to Become a Versatile Veteran Ford’s FE engine has had a rich history that, today, is often overlooked or at least misunderstood. Many of us who have been around awhile have heard the term FE, but not a lot of people of today’s

Taking Over the World of Engine Building

Not many businesses are satisfied with simply maintaining a local clientele. Just as customers typically want bigger and bigger engines, engine shops are looking to grow their business reach outside their town, city or state. In some cases, engine shops reach an international clientele, making their engines and services available to the world. While there’s

Safe Cleaning – Are the Concepts Compatible?

The subject of cleaning is never far from the mind of the modern engine builder or machine shop supervisor. Obviously, parts must be as clean as possible so they can be inspected, repaired if possible and reassembled. The subject of SAFE cleaning is a little less definitive, however.