From engine blocks and heads to oil pans and intake manifolds – engine components are common items that require repair, maintenance or replacement in the shop. Whether you’re working on a car, light-duty truck, heavy-duty diesel or a performance racing vehicle, you may frequently encounter a cracked block or cylinder head that requires a welding fix.

The materials typically used for engine parts can present unique challenges for welding. To overcome these issues, it’s important to choose the right filler metal and keep the base material clean.

Here’s a look at four materials commonly found in engine component repair and some key best practices for successfully welding each metal type.

Aluminum

Aluminum is the most common material used in engine components today. Lightweight and strong, aluminum runs cooler than other materials and is easy to modify. This makes it popular for parts from top to bottom in the engine – including oil pans, intake manifolds, engine blocks, cylinder heads and valve covers.

The selection of the right filler metal is critical when TIG welding aluminum. Most cast aluminum engine components are made from a casting alloy called A356. When welding aluminum, anything higher than 150-degrees Fahrenheit is considered a high-temperature application. To reduce the potential for cracking, choose a 4000-series filler metal that is considered a high-temperature alloy, such as 4043 or 4943.

One common mistake in welding aluminum is to use a filler metal with a higher manganese content, such as 5356. While this is a higher-strength filler metal, it’s typically not recommended for use in high-temperature applications because the higher manganese and magnesium content can result in a weld that is more prone to cracking.

Another issue to keep in mind is that aluminum castings tend to be more porous, which impacts how long the material can be welded before oils and contaminate material is pulled into the heat zone around the weld. This makes it very common to stop and start frequently when TIG welding aluminum in order to keep the area cooler or even to re-clean the weld area between weld passes.

Another issue to keep in mind is that aluminum castings tend to be more porous, which impacts how long the material can be welded before oils and contaminate material is pulled into the heat zone around the weld. This makes it very common to stop and start frequently when TIG welding aluminum in order to keep the area cooler or even to re-clean the weld area between weld passes.

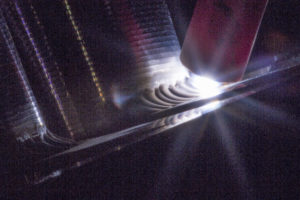

TIG machines with inverter technology and variable frequency controls provide advantages for welding aluminum. The output frequency can be easily adjusted to fine-tune the arc, which allows you to focus the heat and reduce the size of the welding bead.

Reducing the heat-affected zone around the weld with a tighter, more precise arc also helps save time in post-weld grinding and clean-up on aluminum parts.

Cast Iron

Cast iron is another common material used for engine components. Cast iron can be more prone to cracking, so it’s important to watch the heat input during welding. Using a TIG rod that is high in nickel content is recommended, such as Ni99 or Ni55.

The quality of the casting determines how porous a cast iron part is. The more porous the casting, the more difficult it is to weld properly.

This makes cleaning cast iron parts critical. It’s recommended to first soak cast iron parts in a hot tank to boil out some of the oils that are often embedded in the material. If you are working on a cracked or broken part, follow this step by using a carbide cutter to cut out the cracked area and clean it with an acetone or non-chlorinated parts cleaner

.

Because cast iron doesn’t transfer heat well, the heat can stay built-up in one area during welding. Anywhere in the part where cold meets hot, quench cracking can occur when the cold area pulls heat away from the weld zone, ripping the weld apart as it cools. Slowly pre-heating the component before welding can help address this. Pre-heating the part to at least 500-degrees Fahrenheit is helpful — but be careful to not go higher than 1,200 degrees.

Two additional techniques can help reduce the cracking risk in cast iron components. After the part has been welded and while the weld is still hot, peening the welded area can help prevent cracking. This helps knock the weld into the porous areas of the casting as the weld cools. Wrapping the welded part in a thermal blanket or cooling it gradually in a pre-heated oven also helps reduce the risk of quench cracking, since these techniques allow the weld to cool more slowly.

Due to the contamination and oils that may be in a cast iron part, you may also find more success by welding cast iron in very short passes. The material should be thoroughly cleaned before starting, but you may only be able to weld 1 inch or so in a single pass before you need to stop, brush and clean the area again. How much you must stop and start depends on how much contamination from the base material is pulled toward the weld puddle by the heat of the weld.

Steel

Among this list, mild steel tends to be the easiest material to weld. Engine components made from mild steel or stamped steel often include covers or brackets. While these can be MIG welded or TIG welded, keep in mind that TIG welding eliminates any spatter that can get stuck on the engine component and possibly break off later after the engine is reassembled. A 70S-2 carbon steel TIG rod is a good option for these applications.

If the engine part is made from cast steel, you will run into the same cracking issues that can occur with cast iron. Again, the casting quality makes a difference in the ease of welding these materials.

To address the potential for cracking, follow the same procedures for preparing cast steel as you would with cast iron. Use a hot tank bath to clean the part prior to welding and be sure to thoroughly clean the area to be welded.

Parts that are cast do not like to be welded fast because it doesn’t allow the piece to transfer heat slowly. TIG welding is recommended for any cast part because it allows for better control of the heat input. A regular mild steel filler metal such as ER70S-6 or ER70S-2 works well for cast steel parts.

Magnesium

Magnesium is not commonly used in engine parts today, but you may run into this material when working with older parts, such as during a restoration project. Magnesium is lightweight, very strong and less prone to cracking.

The proper technique for preparing and TIG welding magnesium is similar to TIG welding aluminum. The base material should be cleaned well prior to welding. Keep in mind that because magnesium is not as commonly used, filler metals for this material will be more expensive.

Be aware that the metal dust, grindings and shavings from magnesium are highly flammable, so it’s important to keep the weld area extremely clean and to complete weld prep in an area that isn’t vulnerable to fire, flame or high heat.

Final Thoughts

In engine repair or part replacement, weld quality is a critical factor. Potential issues with weld cracking or poor weld quality could result in problematic and costly engine failure later.

Choosing the right filler metal for the base material you’re welding – and following some key best practices for cleaning and welding the material – can help you achieve the best results, whether you’re working with aluminum, cast iron, steel or magnesium.