45-Degree V-Twin Engine Named ‘The Gunfighter’

Running on 100 percent nitromethane with an estimated 375-400 hp, this V-Twin engine named ‘The Gunfighter’ built by Kirby Apathy set a blistering Pro Fuel class quarter-mile record. Find out what went into this history making engine.

Small Block 363 Ford Engine

Just three short years ago, Aaron Yaghoubian was a kid with a hot rod hobby. He didn’t know much about engine and machine work, but after buying Arlington Machine, he got a mentor and put forth his full effort to make himself and his shop a success. Today, he’s rebuilding engines like this small block 363 Ford engine.

S&S-Based Harley-Davidson Evolution V-Twin Engine

A customer in Toronto recently turned to Gregg Dahl and GMS Racing Engines for a Fast Bracket Racing drag bike engine. Dahl answered the call as those engines are his specialty. The result was this 200 hp S&S-based Harley-Davidson Evolution V-Twin engine.

Shop Solutions June 2017

To check lifter bores for finish, burrs or obstruction, I made tools by removing the plunger and internal parts from some lifters. You can stick the lifter on the end of your finger then slide it, with twisting motion, in and out of the lifter bore.

Engine Parts Cracks – How to Fix

One of the essential elements of engine building is making sure heads, blocks, main bearing caps, crankshafts, connecting rods, pistons, cams, timing gears, rocker arms, and flywheels are free from cracks. If you’re doing a complete engine build, checking the intake and exhaust manifolds for cracks is also a good idea – and that includes

Waupaca’s “Time Machine” Machine Shop

The readers of Engine Builder include thousands of skilled machinists who are also car enthusiasts. Over the years, there have been countless stories printed in this magazine about vintage cars. Rarely, if ever, do you read a story like this one about a vintage machine shop that’s been miraculously preserved by just a handful of

V-Twin Validation – How a Harley Discussion Changed an Engine Builder’s Fortunes

What we will be covering here is a general overview of the most common practices and procedures we use in servicing and rebuilding Harley-Davidson engines and things that are unique to V-twin.

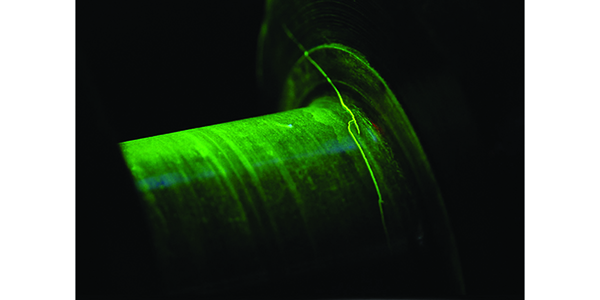

Maximize Your Grinding Efficiency

Today’s shop owner is always looking for the edge, the next big business opportunity – and you may not even realize that your flywheel grinder can be one of the most profitable machines in your business.

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

Shop Solutions March 2016

When vacuum checking 4-valve-per-cylinder heads, it’s hard to tell if it’s both or just one valve that’s leaking. Use your vacuum tester and one of those long inexpensive BBQ or candlestick lighters. Hold the lighter close to the valves and the leaking vacuum will pull the flame in, making it easy to tell which one is leaking.

Five Points to Ponder Prior to PRI

Being an FE Ford fan, and having raced them, and still owning several, “Animal” Jim enjoyed Engine Builder’s article about FE Fords in the April Issue. Jim has been in love with FE’s since his brand new ’63 R code he had when he was 22. In this article he share’s five points prior to the 2014 PRI show.

Advantages of Using an Aluminum Flywheel

By Sam Logan Using aluminum sheds 10-15 lbs. from the rotating assembly of a conventional steel flywheel, but it is the effect the weight loss has on the moment of inertia – the measure of an object’s resistance to changes to its rotation – that contributes the real gains. The lower moment of inertia in

Fidanza Engineering Gets New Ownership, New Name

Now doing business as Fidanza Performance, the company will be lead by ten year company veteran, current president and now owner, Jeff Jenkins. “Lou has been producing great products under the Fidanza name for nearly 20 years and has grown Fidanza to a world recognized brand.” says Fidanza Performance’s new owner/president, Jeff Jenkins. "And we

Removing Dowel Pins With a Claw Hammer (#13)

This way can only be a solution if the hole in the block goes all the way through. OR you can use a readily available claw hammer! Here’s how: Insert the dowel pin between the claw and tap on head of hammer with another hammer until the dowel pin is secured, then pull back on

The Nitty Gritty of Abrasive Safety

Conventional abrasives have kind of taken a back seat to PCD and CBN cutters in the automotive world in the last few years. Since most engines being rebuilt these days are made from multi-alloy components they are more easily machined with PCD or CBN. But PCD and CBN can’t do everything, so abrasives are still

HPBG:Grassroots Engine Market – The Grass MAY Be Greener

Since most people who are involved in racing do not run in NASCAR Sprint Cup, IndyCar or NHRA Top Fuel, we think that it is fair to say anything below these high profile professional racing series is a large group of grassroots racers who support the industry through the dollars they spend, not the sponsorships

Evolving Crankshaft Designs and Applications

In the early days, a crank didn’t have to be very sophisticated or strong because most engines were an inline design, and the loads and speeds were relatively low. Fast forward to today. The evolution in engine technology, power and performance has led to a whole new generation of performance crankshafts that are a mechanical

Engine Builder Shop Solutions: March 2011

Inspection: Vacuum Check That Engine With the advent of foreign castings, some less than stellar, it is important to be more critical than before during inspection. I have a large vacuum pump that I use to vacuum check every engine’s water jacket before it leaves my shop. My pump pulls around 22 inches of vacuum.

Engine Builder Shop Solutions: February 2011

Making the Most of Every Job Quote Often times when my people are quoting a job, I will ask if the customer wanted gaskets, to which the reply is typically, “uh, I don’t know.” That’s just a lost sale every time the phone hangs up if you ask me – it’s only selling part of

Nailing Down The Buick Nailhead

Likethe Small Block Chevy, the Rocket 88 Olds, the Ford Flathead and the ChryslerHemi, the Buick Nailhead engine is one of those that has the immortal smell ofhistory all over it. Yet,unlike its more familiar brothers, cousins and even competitors, the Nailheadhas an aura of mystery about it as well. TheNailhead had a