Sleeves & Liners

I often hear customers ask about the difference between a sleeve and a liner. It’s an understandable question. Automotive guys call them sleeves and diesel guys call them liners. And while they may be used for similar purposes, the perception of what they do may be very different among different groups. Many automotive enthusiasts understand

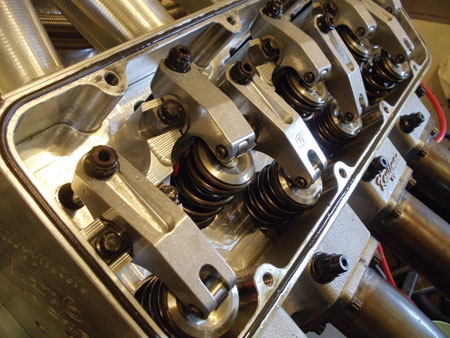

‘Heads Up’ On Today’s Cylinder Heads & Bolts

Some say the air cleaner of an engine is like the front door of a house. That is, it’s what you see first and foremost. And the home owner can use that door to make a statement about the house without anyone seeing what’s inside. Much like what an air cleaner says about an engine

Valve Seat & Guide Machines

A valve seat and guide machine is an essential piece of equipment for any shop that does cylinder head work. So whether you are thinking about upgrading your existing equipment, buying a brand new machine or finding a good used machine, there are a number of important factors to consider as you make your decision.

Keeping Valve Jobs Profitable

Okay, so head work accounts for a large percentage of your business. But is it as profitable as it should be or could be? Do you have a good handle on cylinder head related costs (parts, labor and cleaning)? Are the employees who are doing the head work competent and productive? Is your valve guide

Engine Building Measuring Tools

The French created a measurement system in 1790 called the metric system. While the U.S. has never managed to switch over to it completely, as we were supposed to in the latter half of the 20th century, most automotive techs are familiar with it today because of the fasteners and components on late model vehicles.

New Products for Modern V8 Engines

The numbers aren’t there yet, but engine builders and suppliers are taking notice of the new V8s. What has taken so long? For one, the new engines are more expensive and more complex. Some shops do not have the capability or expertise to work on them just yet, but more and more shops do. One

Installing Exhaust Guides in GM Big Block Engines

The only practical method to determine if this is a problemis to install new a new guide, grind the valve seat, and pressure testthe cylinder head. If both a uniform seat width and leak-free sealaround the guide can be obtained, then the original concentricity wasnot a problem. Also note that the exhaust valve guides are

Your Shop Machines Have No Idea If They

Shop machines don’t have a clue that your tooling is dull, bent, nicked, burred, or the wrong size. It does exactly what you direct it to do, and if your tooling isn’t up to spec you’ll surely junk out a work piece in record time. Let’s start with tooling made from carbide. Carbide tooling comes

Boring and Honing Tips and Tricks

One of the goals of boring and honing cylinders is to size the bores to a specific dimension. If an engine is being remanufactured to meet specific criteria, that usually means boring and honing to achieve a standard oversize (.010?, .020? or .030?). The oversize will depend on the thickness of the casting, how much

Eric Simone Named Sales Engineer at United Engine & Machine Co.

Eric brings more than 15 years of racing and motorsports experience, specializing in race engine construction, development and dyno testing. Eric brings his expertise in racing-piston design along with his natural ability in Customer relations. His responsibilities include Performance Sales & Design, OE accounts and Special Markets. Simone’s initial assignment will include all regions of

Selecting Valve Seats for Gas and Diesel Engines

Hard working diesel engines, performance engines, and engines that run on dry fuels such as propane or natural gas produce a lot of heat in the combustion chamber and often require valve seats that are harder and more heat-resistant. Stellite, chromium, cobalt, tungsten and nickel alloy valve seats are commonly used for such high heat

Valves: When to Reclaim, When to Replace

Performance engine builders can’t afford to take chances with questionable valves because they have to withstand high rpms and temperatures. Likewise, rebuilders who overhaul high dollar heavy-duty diesel and industrial engines want to minimize their comeback risks by making sure the valves they use are either new or have been carefully inspected and reconditioned to

Cylinder Sleeves and Liners

Iron sleeves provide a wear-resistant surface for the piston rings, and they don’t have to be very thick because they are supported by the surrounding block. Cast iron blocks, by comparison, don’t need cylinder sleeves because the iron is hard enough to resist ring wear. If a cylinder is cracked, damaged or worn to the

Take Care of Your Tooling and It

Let’s face it, when you invest in new state-of-the-art equipment, some or most of that investment is in the tooling. That tooling needs proper care – especially if you want your new machine to perform according to the manufacturer’s specs. These newer machines don’t have a clue that your tooling is dull, bent, nicked, burred,

Valve Seat Selection and Machining

When rebuilding a cylinder head for a stock automotive application, a performance engine, or a heavy-duty diesel, what kind of replacement seats should you use if the original valve seats need to be replaced? Should you install new seats that are the same as the original seats, or should you use a different type of

Valve Seats & Machining Guide

Engine cooling doesn’t only happen at at the radiator. The valves (particularly the exhaust valves) take a lot of heat from the combustion chamber and the valve seats have the responsibility of helping to cool them off. The seats draw heat away from the valves and conduct it into the cylinder head, providing most of

Machine Maintenance: Be Straight With Your Jobs By Being Level With Your Machines

Before we get into the meat of this article, let me say thanks to all the fine folks who sent pictures of their shop pets in machine shops around the world. There are some good-looking shop pets out there. Let Me Level With You! Are we on the level? Are you half a bubble off?

The Inside Angle on Valve Seats: What you need to know to go with the flow

No one knows airflow better than the legendary Joe Mondello, who rose to fame back in the 1960s for his race-winning cylinder head work. “Back in those days, we didn’t have flow benches to test our work. Our test bench was the drag strip. If a modification worked and made the car run faster, that’s

Valve Seat & Guide Equipment Selection

Cylinder head work is one of the mainstays of any engine building operation, and these components often require valve guide and seat work to restore them for service or to improve performance. In order for a valve to seat correctly, for efficiency and power, engine builders must replace or bring back to spec all valve

Bringing A GenIII LS1 Stroker Back to Life

Performance engine builing is as old as the first Model T rebuild, but thanks to today’s new engine platforms and a plethora of aftermarket equipment, many engine builders can be intimidated by the scope of the possibilities. But, as we highlight in this article, there are basic engine practices and philosophies that work whether it