Cryogenics is Real and It Works – You Just Can’t See It

Cryogenics is a process in which material such as steel and aluminum are exposed to severe cold, down to -320 degrees F to make them more durable and stabilize the metal or aluminum. The closer you get to absolute zero (-459.67 F) the better, but you better not cross that line of -460 F.

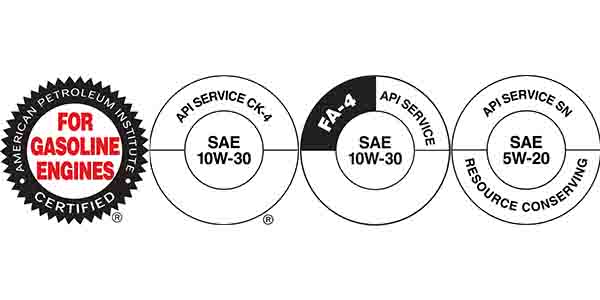

What Your Diesel Customers are Asking About FA-4 Engine Oil

The ROI benefits may outweigh the maintenance challenges With a year of the new American Petroleum Institute (API) CK-4 and FA-4 oil categories under the industry’s belt, many of your diesel customers, especially fleets, have likely switched over to the CK-4 formulation, as that was the engine OEM-approved backward compatible formula. The transition to FA-4

Engine Oil Changes and Innovations

It’s always helpful at the end of each year to reflect on what’s been accomplished and where we think our industry is headed. I think we should do this for the three types of oils you Engine Builder readers typically encounter.

Updates on Proposed API SN PLUS Standard

At the Pan-American Base Oils and Lubricants Conference in Jersey City, N.J., Kevin Ferrick, Sr. Manager of the API Engine Oil Program provided an update on the proposed API SN PLUS standard.

Holley 1050 CFM Gen 3 Marine Dominator Carburetors

Holley/MSD has announced the release of Holley 1050 CFM Gen 3 Marine Dominator Carburetors, which exceed performance demands whether you’re out for high-speed fun or just hitting the lake for an easy cruise. All-aluminum and hard-coat anodized in a gray finish to protect against corrosion in both freshwater and saltwater conditions.

Final Wrap: History Lesson

Retired engine builder and mechanical engineer Bill Hancock sent me a curious picture the other day, one that points out how far we’ve come – and, how we may not really know what we think we do about this industry.

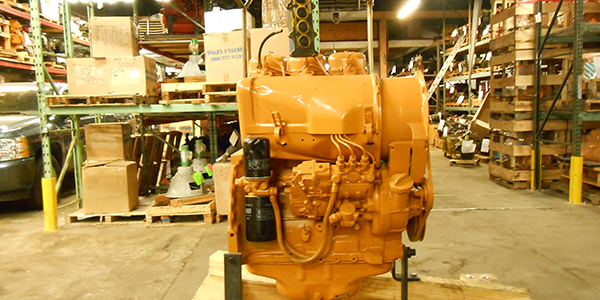

Industrial Engine Rebuild Opportunities

Rebuilding industrial engines is a growing business for many engine builders and shows no signs of slowing down.

REBUILDING THE 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would

Wet & Dry Sump Oiling Systems – Choosing the Right System for the Right Job

If you are building a customer’s “dream engine” what type of oiling system should you use? The answer to that question will depend on the application (street, drag, circle track, road race, off-road or marine), engine RPM and how much your customer is willing to invest in a lubrication system. Your choices may also be

Industry Still Strong, Say Readers – Engine Builder Readers Tell Us Business Has Changed, But Opportunity Still Remains

For more than 50 years, Babcox Media has covered the rebuilding industry on a monthly basis. At least 633 issues of Automotive Rebuilder and, since 2000, Engine Builder has been dedicated to the business of machining, building, rebuilding and remanufacturing engines. In our very first issue, we made the promise that we would be devoted

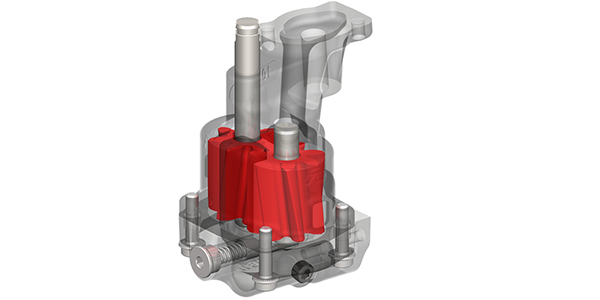

The Science Behind Wet Sump Oil Pumps & Oiling System Upgrades

All automotive internal combustion engines are equipped with some type of pressurized oiling system. Oil lubrication is essential for reducing friction, preventing wear and cooling vital engine components. Pumping oil to the main and rod bearings creates a friction-reducing hydrodynamic film between the bearings and crank that allows the crank to spin with minimal friction.

V-Twin Validation – How a Harley Discussion Changed an Engine Builder’s Fortunes

What we will be covering here is a general overview of the most common practices and procedures we use in servicing and rebuilding Harley-Davidson engines and things that are unique to V-twin.

Making the Plunge into CNC

Computer Numeric Controlled (CNC) machines are changing the way many machine shops build engines. CNC provides a level of automation, sophistication and accuracy that manually operated machines can’t match. CNC also has the potential to dramatically increase productivity and profitability.

Engine Bearing Technology – The Spin on Spun Bearings

One of the worst failures that can occur inside an engine is a spun bearing. It can happen in a stock engine, race engine, gasoline engine or diesel engine. A spun bearing is bad news because it usually seizes itself around the crankshaft journal. What happens next depends on the bearing’s location.

Preventing Connecting Rod Failures

Connecting rods are some of the hardest working parts inside an engine. Fortunately, rod failures from severe overloading don’t happen that often. However, they can occur in racing or extreme street performance applications. So here’s what you need to know.

Maximize Your Grinding Efficiency

Today’s shop owner is always looking for the edge, the next big business opportunity – and you may not even realize that your flywheel grinder can be one of the most profitable machines in your business.

In Memoriam: Aaron Stolberg, Founder of A&A Midwest/EngineQuest

Aaron Stolberg, founder of A&A Midwest/EngineQuest in Chicago and later Las Vegas and longtime PERA member, has passed at age 90.

Bill Riordan Joins NPR of America

NPR of America has announced that Bill Riordan has been appointed to the role of, Sales High Performance Piston Rings. With an extensive career in the automotive engine parts and the high performance industry, including 24 years with MAHLE Clevite/Dana Corporation, Bill is a welcome addition to the sales team at NPR of America.

Engine Builder Readers Qualify for Special AETC Discount

Thanks to a special discount code, all readers of Engine Builder magazine and subscribers to the Engine Builder newsletter are eligible to attend this year’s Advanced Engineering Technology Conference at a special savings!

Foley Engines Celebrates a Full Century of Service

Foley Industrial Engines located in Worcester, MA is celebrating its 100th anniversary as a warehouse distributor of industrial engines and parts. Founded in 1916, the company has evolved over the years to become a leading specialist in Perkins and Deutz engines.