11th Annual Edelbrock Car Show

Edelbrock has announced its 11th Annual Car Show, which will be held on Saturday, May 14, 2016. On Friday, May 13, 2016, Edelbrock will once again be opening the doors of its corporate headquarters and manufacturing facility to the public for free shop tours. Participants will get the opportunity to take a guided tour of Edelbrock’s Research & Development, Manufacturing and Quality Control departments.

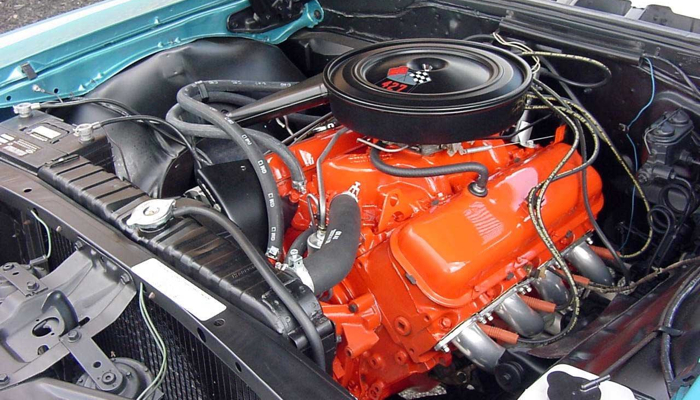

Old Cars Never Die – Not If I Can Help It

I have not worked on everyday, common engines for years. Everyone who comes into my shop is a hobby-level special car enthusiast. I build all types of performance American brand engines. A huge part of my business has become building and rebuilding engines for classic cars, which it turns out, there is an adequate market for engine builders.

Growing Your Perfect Customer

The most powerful advertising tool you have is existing customers talking about your business to others. When THEY tell YOUR story, it can be a powerful motivational tool.

Fastener Intricacies

At first blush, using fasteners properly seems like a straightforward task: tighten them to spec and all is well. But in reality, there are many nuances in the selection and application of fasteners that can make the difference between a well-built engine and a candidate for self-destruction.

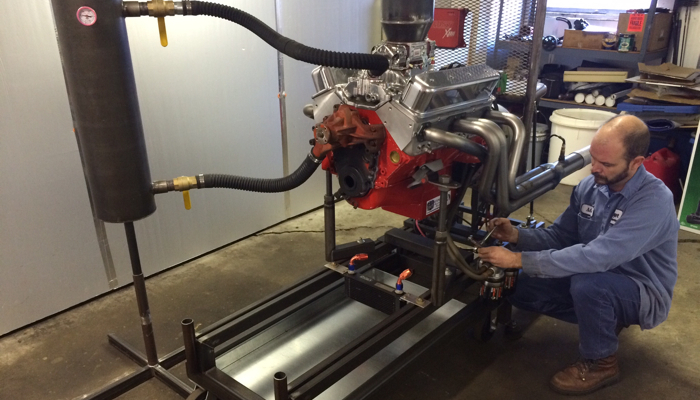

Off-Season or On-Season?

The phrase “off-season” implies that another year of excitement is over, whether that be football, baseball, basketball, or in this case, auto racing. It’s true, the racing season has come to an end for 2015, and the off-season is underway. However, while many drivers might have more free time now than they did during the race season, this time of the year is a very different beast for engine builders.

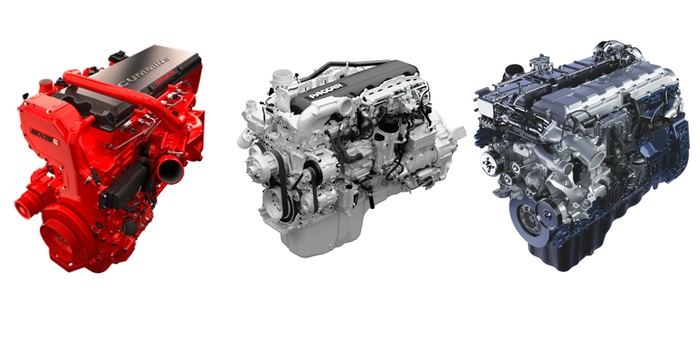

Dark Days of Diesel?

Think about the diesel engine over the last 30 years. From a rattling bucket of bolts that often got a frown from people it’s become a highly sought-after engine among the younger high school generation. Who would ever have imagined that one?

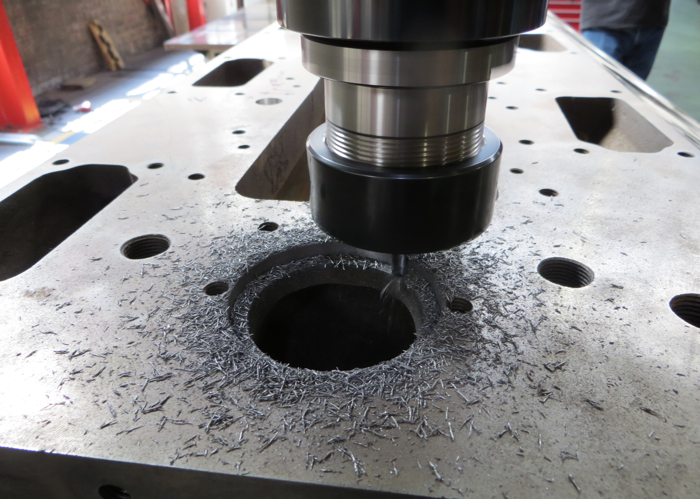

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

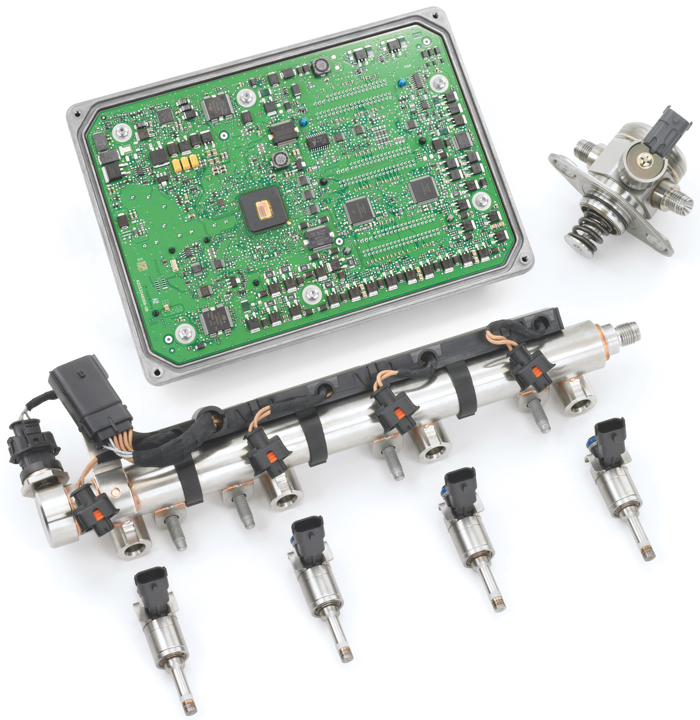

Direct Injection Gas and Diesel Technology

Direct injection is becoming standard on more and more late-model vehicles in both gasoline and diesel versions. These systems can be a diagnostic challenge, but with the right foundation, problems can be solved profitably. A better understanding of how they work can help you help your installer customers do a better job.

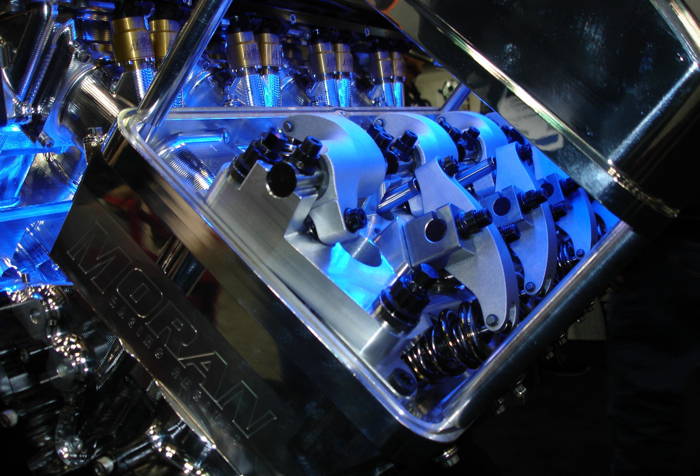

Keep the Valvetrain on Track

The key to choosing the right valvetrain components is to match the parts to the application. It sounds simple enough, yet many valvetrain component suppliers tell us there are a lot of misconceptions about what kind of parts are best for different kinds of performance applications.

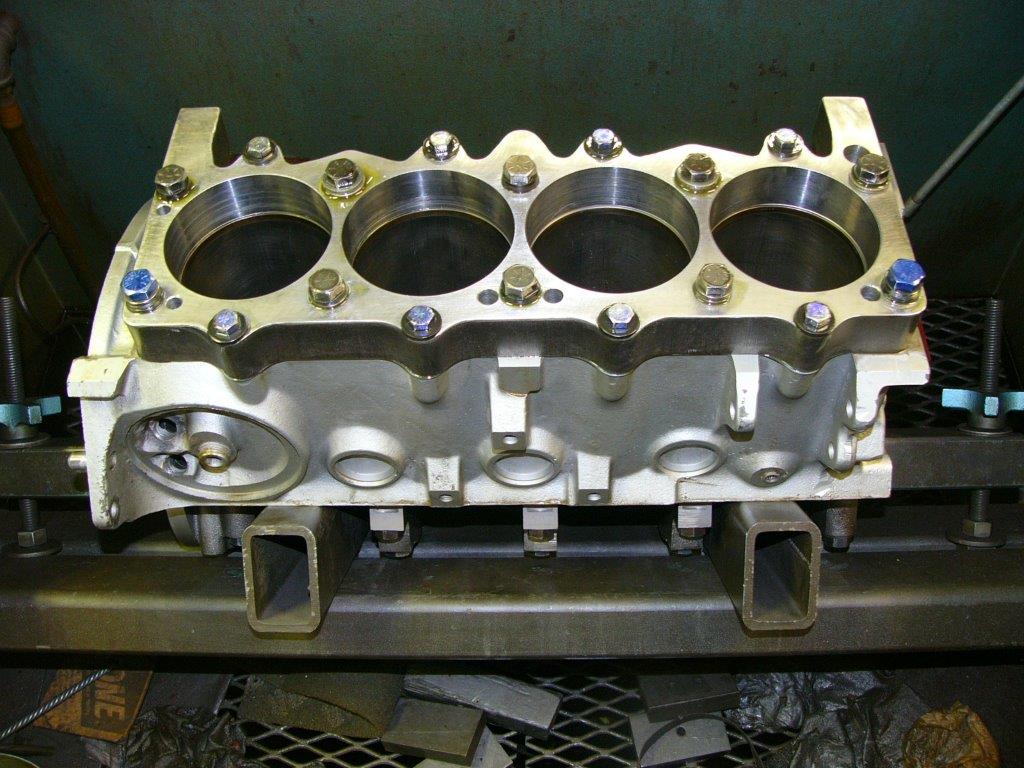

Liners and Sleeves

Sleeves are certainly not new technology and experts say that, for the most part, engine builders and machine shops understand the use and functionality well. But is a liner and a sleeve the same thing? Is a hole just a hole? Publisher/Editor Doug Kaufman takes a deeper dive.

Stroker Mania

Years ago, it was a big hassle and expense to stroke an engine. But one reason stroking is so popular today, is the convenient availability of the parts – usually sold in kit form to acquire those extra cubes. Many different strokes are offered from many different suppliers.

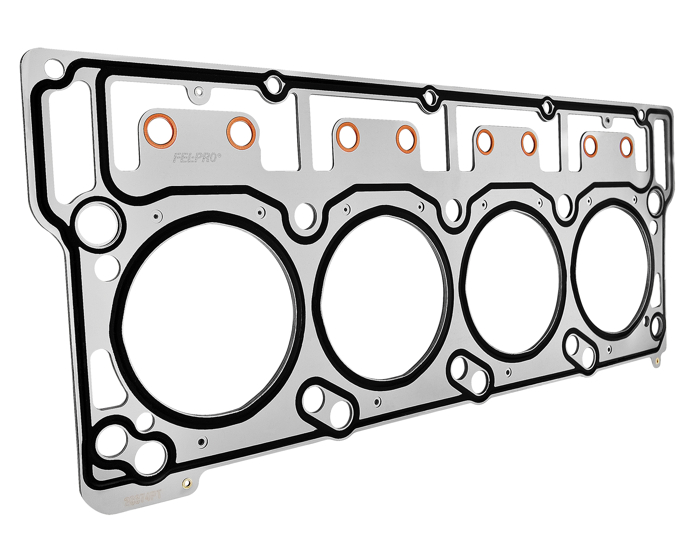

Diesel Performance Head Gaskets

The stock head gaskets that are used in most light truck diesel engines are robust enough to handle peak combustion pressures in the 1800 to 2200 PSI range, but may not do so well at higher pressures if the engine has been tweaked to produce more power.

Shop Solutions July 2015

I made a quick and accurate piston ring aligner for checking end gaps out of a .030 over, 454 Chevy flat top piston. Just chuck the piston in a lathe and turn the ring lands down to a little under 4.000˝. The bottom of the oil ring land is about .950˝ from the top of the piston, and will align the ring in the block.

King Bearings Oversized XPG Main Bearings for Subaru EJ

King Engine Bearings has released two new oversized main bearing kits for the Subaru EJ series engines. King’s new oversize bearings can reduce machining and labor costs and therefore lower the overall repair costs passed on to the vehicle owner.

Choosing the Right Oil Pump

Choosing a replacement oil pump for an engine you are building or modifying is a process that requires some thought. Original equipment oil pumps are usually adequate for most stock applications – but some are not, especially if an engine is being modified.

Losing a National Treasure – True Craftsmanship

No, this isn’t an adventure story about great works of art or even our national monuments – it’s even more dramatic. I’m referring to the GREAT ones: the machinists we all know who have been around far longer than these fancy new CNC machines. I’m talking about the true craftsmen that built this industry long before many of you were born.

DBB Acquisition LLC Acquires Dura-Bond Bearing Company

DBB Acquisition LLC has announced that it has completed the acquisition of Dura-Bond Bearing Company, a division of privately held Melling Engine Parts. Dura-Bond is a manufacturer of Cam Bearings, Bushings, Valve Seats and Hardware for engine and transmission rebuilding since 1947. The Company is based in Carson City, Nevada. Terms of the transaction were

Building Stocks and Sprints

To be successful in the performance market, you need to deliver a product or service that a competitor not only needs, but will help make him a winner. To find that product or service, you need to spend time with them to understand the needs of the racers.

Why Diesels Have Become ‘Greener’ and How You Can Benefit

For several years now, clean air and better fuel economy have been the primary focus of the transportation industry. Back in the 1970s, the clean air agenda came into full swing and it literally crippled performance as well as reliability. At that time, the diesel industry wasn’t being regulated by any of these emissions standards, but changes were on the horizon.

Think Your Business Won’t Change? Think Again

All great companies have one thing in common: They realize industries and consumers need change, so they follow their customers. Your business is no different. Over the decades, the engine building business has transformed as well. So how are you changing with it?