September 2014 Shop Solutions

One of the most important factors in engine bearing design is a proper fit between the bearing and housing. Except for thrust washers, nearly all bearings are an interference fit. This means the bearing is slightly larger than the hole it fits into. In bushings, we refer to this as “Press Fit.”

MSD Pro-Billet Distribution for Ford Y-Block Engines

The Pro-Billet Y-Block Distributor, PN 83831, is built around a CNC-machined billet aluminum housing that is fit with a sealed ball bearing guide for stability and endurance.

MSD Pro-Billet Distributor For 392 HEMI Engines

For anyone with a 392 HEMI, they’re going to be excited to hear about MSD’s new Pro-Billet Distributor, which is based on a CNC-machined billet aluminum housing for incredible strength and precision tolerances.

Chevy’s 348 and 409 ‘W’ Motors

Chevy’s 348 and 409 ‘W’ motors are having no problem keeping their popularity going. In fact, judging by the numbers of high quality parts being made for these motors today, they may even be more popular than ever. The quick and dirty of W motors and their parts today is that you can sit at

Replacing Crankshafts, Connecting Rods and Bearings

The crankshaft, connecting rods and bearings are extremely important in every engine build, whether mild or wild, because they convert the reciprocating motion of the pistons into rotational torque. The longer the stroke, the greater the leverage effect and the greater the torque output of the engine. There are three things that need to be

Chrysler Delivers V8 HEMI Hellcat on Wheels

The much-anticipated HEMI Hellcat engine is Dodge and SRT’s first application of V8 supercharger technology, delivering an amazing 600-plus horsepower. This supercharged 6.2-liter HEMI V8 Hellcat engine is the most powerful V8 engine ever produced by the Chrysler Group. According to Chrysler, its breakthrough supercharged engine features a forged-steel crankshaft with induction-hardened bearing

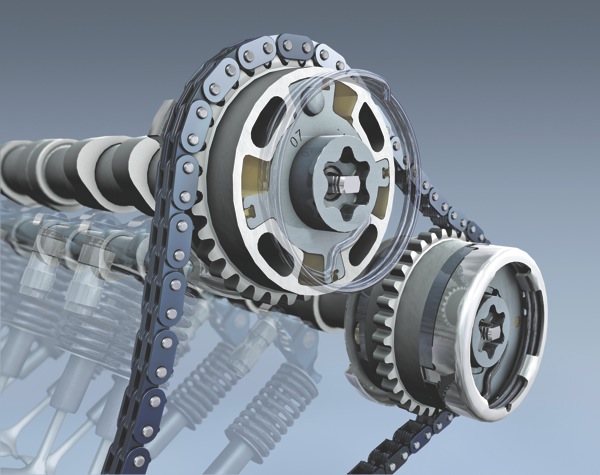

The Inner Workings of Variable Valve Timing

Variable Valve Timing (VVT) is a way to advance/retard valve timing, and change duration, overlap and even lift in some applications while the engine is running. VVT is computer-controlled and typically uses oil pressure to change the position of a phaser mechanism on the end of the camshaft to advance or retard cam timing. VVT

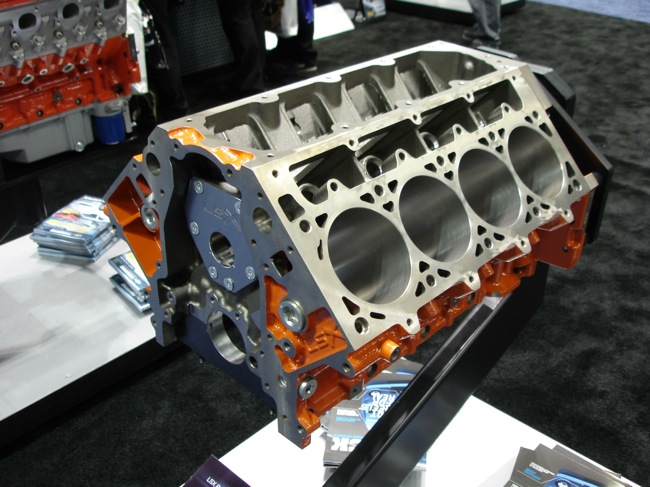

Building Blocks: The Foundation of Any Engine Build

Every engine project starts with the block because the block is the foundation for everything else that follows. The block determines bore and stroke, camshaft and lifter location, oil pump location and oil galley configuration, what kind of main bearing caps can be used to support the crankshaft, and what kind of cylinder heads, oil

Guide Discusses Securing Cylindrical Assemblies

20-Page Brochure Highlights Increase in Joint Strength and Reduction in Assembly Costs Henkel Corporation has created the Loctite® Retaining Compound Design Guide, a new 20-page brochure available in print and online that provides detailed information on anaerobic retaining adhesive technology and its engineering and cost benefits, real world applications and product and equipment options. Loctite

New 2014 Dura-Bond Catalog Available

The new catalog features many new applications complete with photos, competitors’ interchange, conversion reference charts, and a powder metal valve seat technical information and installation instruction manual. Company: Dura-Bond Bearing Company www.dura-bondbearing.com Dura-Bond Bearing Company recently introduced its new 2014 engine parts catalog that includes the following feature items: • The “All-Round Cam Bearings” • Oversize

Diesel Cranks and Connecting Rods

The demand for mid-size diesel performance products continues to grow. There tends to be two sides of the mid-size diesel spectrum: on one side there is street performance and on the other there is all-out race. Street performance diesels deal mainly with engine parts that are primarily for bolt-on applications and can make great power

Engine Builder Shop Solutions: June 2013

Removing Stubborn Dowel Pins Do you ever have solid dowel pins that are worn or tapered, and the slap hammer slips off no matter how tight you make it? Add a dab of valve lapping compound to the dowel pin. It works wonders. Most of the time the pin slaps right out. Jeffrey Myers MAR

What’s on the Dyno?

While automotive trends come and go, true collectors develop a personal taste that grows more interesting and eclectic as time passes. Sometimes it comes down to owning things truly unique and one-of-a-kind. This GMC inline-6 is all of that and more. The 302 cid inliner is one of the most sought after inline-6 engines, and

Parts Making With Your CNC

Computer Numeric Controlled (CNC) machining allows engine builders to achieve almost unbelievable levels of accuracy and consistency. The programmability of a digital computer not only automates the operation of the equipment but also provides a level of repeatability that can’t be matched by manual equipment. That’s why CNC has been the backbone of virtually all

A New ‘Finish’ in Honing

For years, engine builders have been honing cylinders with a coarse stone followed by a finishing stone. Then ring materials changed, requiring an additional very fine finishing stone to follow. Now current technology demands an added step to create an even cleaner, burr-free finish. However, even with these conventional honing techniques, peaks of folded and

Rebuilding Chrysler’s ‘Revived’ Engine Family

Casting numbers, VIN codes, components and processes to rebuild/remanufacture these engines are compiled for Chrysler’s newly revised engine family including 4 cylinders, V6s and V8s Chrysler made some major changes in their engine line-up starting in ’07. They replaced their four cylinder engines in everything but the PT Cruiser in ’07, updated the 4.7L V8

Engine Builder Shop Solutions: February 2013

5 Tips For a Manual Milling Machine Editor’s Note: A manual milling machine is typically at the heart of every machine shop. In the following, Jim Kovach gives some useful tips on how to get the most from your mill. 1. Always use a high-quality machinist’s square on the mill. You will be surprised how

Engine Blueprinting Basics

The top professional divisions in racing today for the most part run engines that are built to comply with a very strict set of rules for each series. In NASCAR, where the engines have been roughly the same 358 cid V8 for decades, the power output has steadily increased. Engines of the same brand that

Takin

Back in the old days, the late ’90s, when the economy was strong and incomes were high, people had a lot more money to put toward their favorite hobby, which for many was a souped up car that could be driven on the street but maybe also a little on the track as well. Today,

Diesel Connecting Rod Reconditioning

As a result, connecting rodreconditioning is a critical part of all diesel overhauls. Uponteardown, the old connecting rods are inspected, magnafluxed, checkedfor alignment, parting surfaces re-machined, and new rod bushingsinstalled and pin-fit. At the same time, the rod bolts are measured forstretch. This is all normal, day in, day out activity at any heavy duty