Every engine project starts with the block because the block is the foundation for everything else that follows.

The block determines bore and stroke, camshaft and lifter location, oil pump location and oil galley configuration, what kind of main bearing caps can be used to support the crankshaft, and what kind of cylinder heads, oil pan and bellhousing can be bolted to the block.

If you’re starting with a used block, you have to clean it and thoroughly inspect it to make sure the block is free from cracks or excessive wear in the cylinders, cam, crank and lifter bores that would make it unsuitable for rebuilding. A seasoned engine block that’s accumulated a lot of miles can provide a stable foundation for a performance rebuild.

But the accumulated stress and wear that comes with lots of miles also increases the odds that the block may have reached the end of the road and is better suited to serving as a boat anchor. With every passing year, it gets harder and harder to find good rebuildable used blocks for engine projects — especially the more desirable engines and displacements. What’s more, some types of racing specify a certain type of block (such as Midwest 305 Sprint Cars which require a cast iron 305 block). So if you can’t find a stock block that meets the requirements, your only option is to go with an aftermarket block.

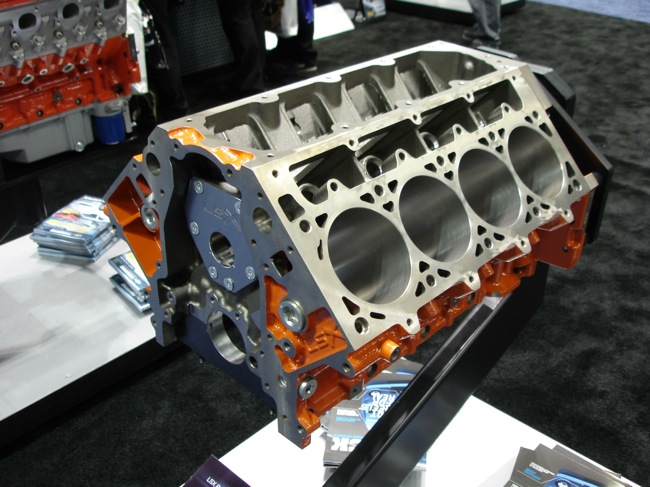

Aftermarket Engine Blocks

If you can’t find a good original equipment engine block for a project, or the original equipment block doesn’t have enough clearance, strength or rigidity to handle the kind of power you want to make, there are plenty of aftermarket blocks from which you can choose. Aftermarket blocks are usually purpose-built blocks that feature numerous improvements over the original equipment design that they are based upon.

Today’s thinner OEM castings save weight and cost, but also allow more cylinder bore distortion when power levels exceed factory limits. Push them too far and they often blow up!

A stock Chevy small block with two bolt or four bolt main caps can usually handle 450 to 500 horsepower, but when you start pushing it to much higher horsepower levels with nitrous oxide, or lots of boost pressure from a turbo or blower bad things start to happen in the cylinders and bottom end. For such applications, an aftermarket block may be the only safe way to go.

Cylinder bore distortion affects piston ring sealing, so the more the bores distort under high loads, the greater the blowby past the rings. Blowby wastes power so the more rigid the block, the better.

An aftermarket block that has more metal around the cylinders will experience less bore distortion and produce more usable horsepower – up to 20 to 30 more hp in some cases with no other changes!

Many aftermarket blocks have thicker deck surfaces to maintain a better head gasket seal and to reduce the risk of cracking. More metal in the deck also means they can be resurfaced down the road without weakening the block.

If you’re building a stroker motor and need a taller deck height to accommodate more piston travel, you can usually get that too. It’s the same with raised camshaft locations for added crank clearance. Many aftermarket engine blocks are available with standard deck heights or taller deck heights, standard cam locations or raised cam locations, and/or with oversized cam bores to accept cams with oversized journals.

Another plus with some aftermarket engine blocks is that you have greater flexibility with the kind of cylinder heads that will fit the motor. One supplier makes a modified LS Chevy block that uses a SB Chevy crank and oil pan but accepts late model LS cylinder heads. The cam in this particular block is 0.135 inches higher, allowing the use of a larger 55 mm camshaft with a 4-inch stroke crank. Some suppliers also add extra bolt holes around the cylinders so you can use special heads with additional head bolts for better head gasket sealing.

What kind of crankshaft do you want to use? Many aftermarket blocks for SB Chevy applications give you the choice of using a 350 or 400 Chevy crank. You can also get blocks with billet steel main caps and a splayed bolt pattern for added strength.

Some blocks have special reinforcements in the lifter valley and on the outside of the cooling jackets to improve stiffness and support. These kind of improvements are especially valuable in high horsepower applications were rigidity and strength are critical.

The back of the block is another area where aftermarket suppliers give you more flexibility. You can get blocks with a standard bell housing configuration, a late model configuration or a sprint car bell housing mounting pattern. The blocks may also have multiple motor mount bosses so it can be used with a variety of different mounts.

When Bigger is Better

Do you need more displacement? Adding cubic inches is a great way to add horsepower and torque. You can get SB Chevy blocks with 4.5 inch bore spacing and BB Chevys with 5-inch (or larger) bore spacing.

One supplier has a block with 5.300 inch bore spacing that can handle cylinder bores up to 5.080 inches and a crank with a full 6-inch stroke. Do the math and it adds up to 973 cubic inches.

Others are pushing the envelope to over 1,000 cubic inches! The point is, if you can dream it somebody is probably making it or will custom make it for you.

A lot of street performance applications are running BB Chevys over 600 cubic inches these days, so to achieve that kind of displacement you need a block that can handle bigger bore diameters and a long stroke crankshaft.

You can also get blocks with standard or oversized lifter bores, and fitted with bronze bushings for added durability if that’s what you want. Some also offer blocks with relocated lifter bores to improve valvetrain geometry.

Getting Better Lubrication

Stock oiling systems often leave much to be desired when it comes to performance engine applications. Some aftermarket blocks have reconfigured oil galleries for better oil flow to the lifters and valvetrain.

On factory LS engines, for example, cam and lifter bore wear is often a problem, making up to 50% of salvage blocks unusable. By changing the way oil is delivered to the lifters, these kind of wear problems can be eliminated.

On SB Chevy engines, oil is fed to the cam bearings at the 6 o’clock position, which is fine for a stock valvetrain. But when stiffer valve springs are used, the cam can be pushed down against the oil feed holes and restrict oil flow to the cam bearings. Relocating the oil feed holes to the 5 o’clock position solves this problem as assures a steady supply of oil for the cam.

Many blocks give you a choice as to the type of oiling system you can use (internal wet sump or external dry sump), and the oil pump and filter location on the block. Different oil pan rail configurations may also be available giving you more freedom as to the type of oil pan that can be bolted under the motor.

Addressing Cooling Issues

Cooling problems in many original equipment blocks are caused by limited coolant circulation between the cylinders.

Some aftermarket blocks have larger water jackets and extra ribbing to help cool the engine. These kind of improvements are especially important with large displacement stroker engines that need more cooling.

Cast Iron and Aluminum Blocks

You can buy aftermarket performance blocks in a variety of materials including cast iron, Compacted Graphite Iron (CGI), cast aluminum or machined billet aluminum.

Cast iron blocks are usually the most affordable option, and often use a higher grade of cast iron that what is used in many OEM blocks. CGI blocks use a stronger, higher density form of iron which improves overall strength and wear resistance. CGI also allows portions of the casting to be thinner for added weight savings. But CGI can be very difficult to machine because of its hardness so there are some tradeoffs if you choose to go this route.

You can buy unfinished blocks and do your own machining, partially machined blocks that only require final honing and clearancing, or fully machined blocks that are ready to assemble.

Often, the cost difference between a raw casting and a fully machined casting isn’t that much (less than $100 in some cases), so you need to consider the advantages of doing the work yourself or having the supplier do it for you.

The main advantages with aluminum blocks are lighter weight (up to 100 lbs. or more depending on the engine), easier machinability and better cooling.

Aluminum blocks may be made from a high grade 357-T6 aluminum or other alloy. Aluminum blocks are usually sleeved, typically with centrifugally cast ductile iron sleeves. Iron sleeves are compatible with all ring types and added much needed stiffness to an aluminum block. Most are dry pressed in sleeves which means the sleeves can be replaced if necessary if a cylinder is damaged or worn.

There are also some wet sleeve kits for cast aluminum blocks, but they require extensive CNC machining to install. You can also get aluminum blocks with cooling jackets, partial cooling jackets or a solid block with no cooling jackets at all (for drag racing).

Cast aluminum blocks are expensive, however, and may cost $4500 to $5500 or more depending on the application and whether you are buying an unfinished block or a machined block. Additional weight reduction by CNC machining adds to the cost.

The most expensive aftermarket blocks are ones that are CNC machined from a solid chunk of aluminum. Most of these engines are a work of art to behold – and are priced accordingly. Some billet aluminum blocks can cost upwards of $12,000 dollars, so they are mostly toys for the big boys like Top Fuel and Alcohol dragsters and IHRA Pro Stock race cars.

A billet aluminum block is typically much stronger than a cast aluminum block (36% higher tensile strength and 66% higher yield strength according to one supplier of billet blocks). It’s also 20 to 30 pounds lighter than a typical cast aluminum block thanks to the intricate and precise machining that goes into making one of these blocks. The stiffness of the block also means less bore distortion and more usable horsepower.

Ductile iron dry sleeves are used in most billet aluminum blocks for the same reasons they are used in cast aluminum blocks, to add stiffness, durability and serviceability.

Because billet aluminum blocks are all CNC machined, they are custom made one-at-a-time and offer a lot of machining options (bore size, deck height, cam and lifter location, etc.). These are built to spec engines so you can get just about anything you want.