Shop Solutions July 2016

Sometimes machine shops are called on to solve more than engine issues. Toyota rear axles are difficult to disassemble and usually require replacing the reluctor gear when replacing the bearings. I made a jig to drive the axle out of the housing using my press.

Industry Still Strong, Say Readers

Engine Builder readers tell us business has changed, but opportunity still remains.

S.B. International Names Tom DeBlasis VP of Sales

S.B. International, Inc. (SBI) of Nashville, Tennessee, recently announced the appointment of Tom DeBlasis as vice president of sales effective July 15, 2016.

A Job Well Done

If Timm Jurincie stopped accepting engine work today at his Avondale, AZ shop, Tuf-Enuf Auto & Marine Performance, he would still have enough work to last until September. Tuf-Enuf, which focuses on performance marine engines and street strip motors, is a sought-after engine shop in the Avondale and Phoenix area despite not advertising.

Shop Solutions May 2016

One of the most difficult heads to pressure test is the BMW DOHC 6 cylinder. It is nearly impossible to plug the water outlet on the side of the head, until now. A “T handle drain plug” from a boat is the perfect size, and easy to install and remove.

SOPUS Products Recalls Shell ROTELLA Ultra ELC 50/50 Pre-Diluted Antifreeze/Engine Coolant

SOPUS Products is requesting return of all batches of one gallon bottles and 55-gallon drums of Shell ROTELLA Ultra ELC 50/50 Pre-diluted Antifreeze/Engine Coolant and one batch (B2811293U063/30Sept15) of 55-gallon drums of Shell ROTELLA Ultra ELC Antifreeze/Coolant Concentrate currently in the marketplace because these products were undertreated with bitterant.

Shop Solutions January 2016

Sometimes the front of Oldsmobile blocks get warn and chewed up by the camshaft flange. This is often caused by additional load from a high pressure or high volume oil pump, which makes the distributor work harder and pulls the cam back towards the block.

A Peek at the Small Bore Diesel Market

If I’ve learned one thing above all else since writing for this industry, it’s that there are always new opportunities. The trouble sometimes is just finding where those opportunities lie. One of these opportunities recently brought to my attention can be found in the small bore diesel market.

Shop Solutions November 2015

When assembling an engine, one of the most overlooked items is the timing chain sprocket alignment. The upper and lower gears should be installed and alignment checked with a straight edge. I have seen them as far as .020˝ off.

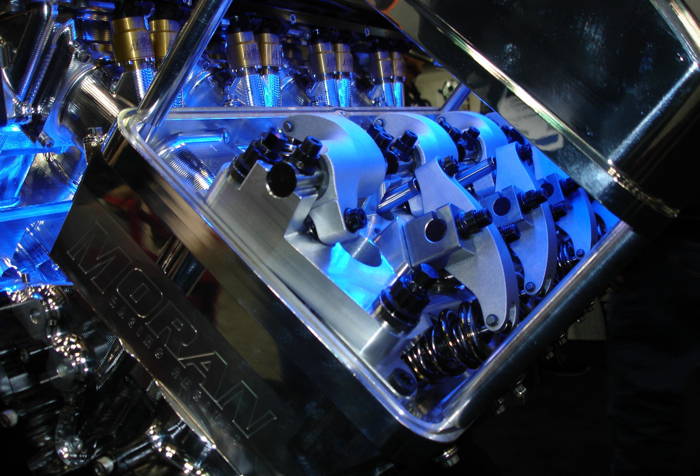

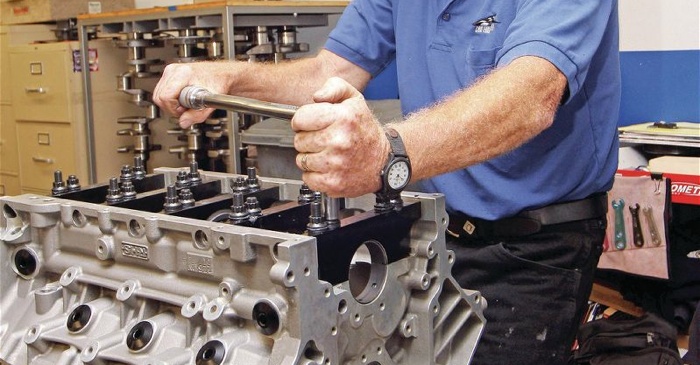

Keep the Valvetrain on Track

The key to choosing the right valvetrain components is to match the parts to the application. It sounds simple enough, yet many valvetrain component suppliers tell us there are a lot of misconceptions about what kind of parts are best for different kinds of performance applications.

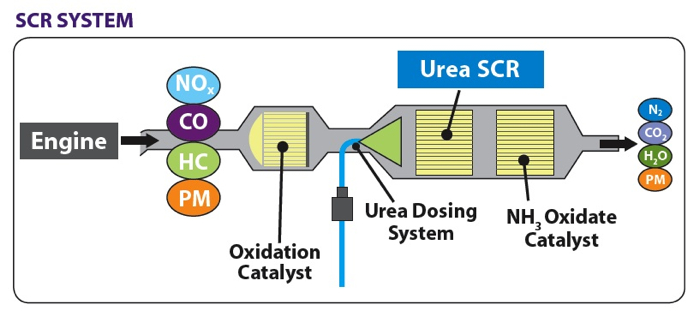

What Is Selective Catalytic Reduction?

Selective Catalytic Reduction (SCR) is a proven and advanced active emissions control technology system that injects a liquid-reductant agent through a special catalyst into the exhaust stream of a diesel engine. The reductant source is usually automotive-grade urea, otherwise known as Diesel Exhaust Fluid (DEF).

Shop Solutions July 2015

I made a quick and accurate piston ring aligner for checking end gaps out of a .030 over, 454 Chevy flat top piston. Just chuck the piston in a lathe and turn the ring lands down to a little under 4.000˝. The bottom of the oil ring land is about .950˝ from the top of the piston, and will align the ring in the block.

Machine Shop Market Profile

As we move through our 51st year of covering this industry, the staff of Engine Builder recognizes that old adage – the more things change, the more they stay the same. What’s changed about this industry is, well, pretty much everything. What’s stayed the same is the dedication and hardwork of the professionals who keep engines running and customers happy.

Allison Power

In December, we discussed the use of Allison engines – originally designed for use in WWII fighter planes – in watercraft applications. Now, we’ll pick up the story of these versatile powerplants finding success on dry land.

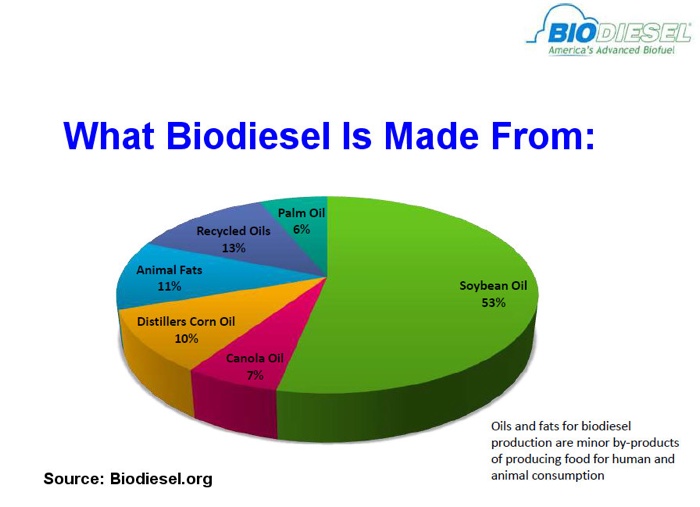

Building for Biodiesel

Some people have a negative view of biodiesel. They say it gums up the fuel pump and injectors. They say it gels in cold weather. They say it’s diverting food resources to make fuel. They say it’s too expensive and can’t compete economically with conventional No. 2 diesel fuel. Then they hear that diesel engines burning biodiesel are winning pulling championships, drag races and setting new land speed records. Maybe biodiesel isn’t so bad after all.

EngineQuest 2015 Parts Catalog

EngineQuest’s 2015 parts catalog is packed with new and hard-to-find parts for many domestic and foreign applications and also contains detailed product specifications that will help you select the right part for the powertrain you’re working on.

Turning Over Industrial Engine Business

Engine builders today are diversifying their businesses in order to maintain a healthy, steady stream of business and cash flow. One such area of opportunity lies within the industrial engine market. Industrial engines are a broad category that essentially covers any off road engine. Read how your shop can get in on the action.

Choosing the Right Camshaft for a Performance Engine

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

November 2014 Shop Solutions

One of the main problems with blocks that need to be align-bored is the lack of squish between the main cap and the block. What I am referring to is the interference fit between the cap and main register that holds the cap in alignment, and is the reason a light tap is needed to seat the cap. If the caps do not fit tight, the crank will not be held as solidly as it was intended, and also results in inconsistent bearing clearances.

Company Innovations

While technology in general was the primary answer to what innovations helped grow the industry over the past 50 years, when asked about innovations within their own companies that have helped the industry, the answers were more specific to certain engine parts. “Over the years a number of Sunnen innovations have been standards of the