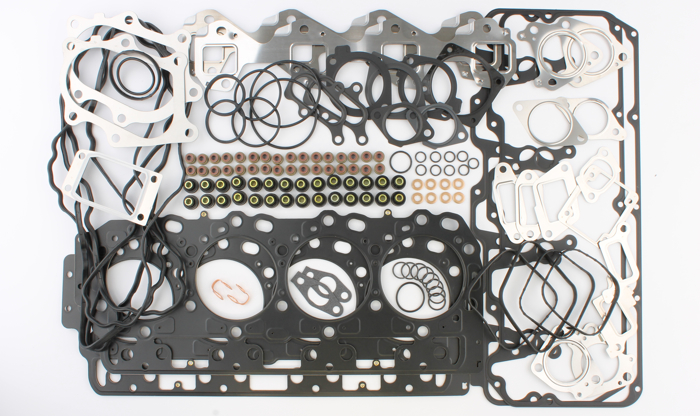

Cometic 2001-2007 GM Duramax 6.6L Diesel V8 Gaskets

The new 2001-2007 GM 6.6L Duramax MLS head gasket utilizes a load control embossment for superior combustion chamber sealing and improved clamp load around the cylinder without increasing bore distortion.

Jiffy-tite Signs Endorsed Product Sponsorship with DIESEL Motorsports

Jiffy-tite finalized an endorsed product sponsorship deal with DIESEL Motorsports recently, making the Lancaster, New York company the official quick-connect fluid fitting sponsor for all events of the 2016 DIESEL Motorsports season.

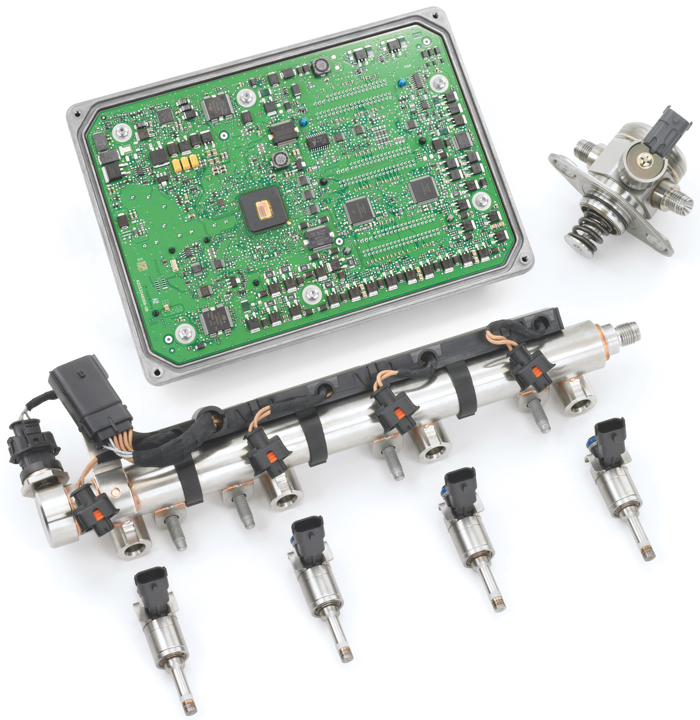

Direct Injection Gas and Diesel Technology

Direct injection is becoming standard on more and more late-model vehicles in both gasoline and diesel versions. These systems can be a diagnostic challenge, but with the right foundation, problems can be solved profitably. A better understanding of how they work can help you help your installer customers do a better job.

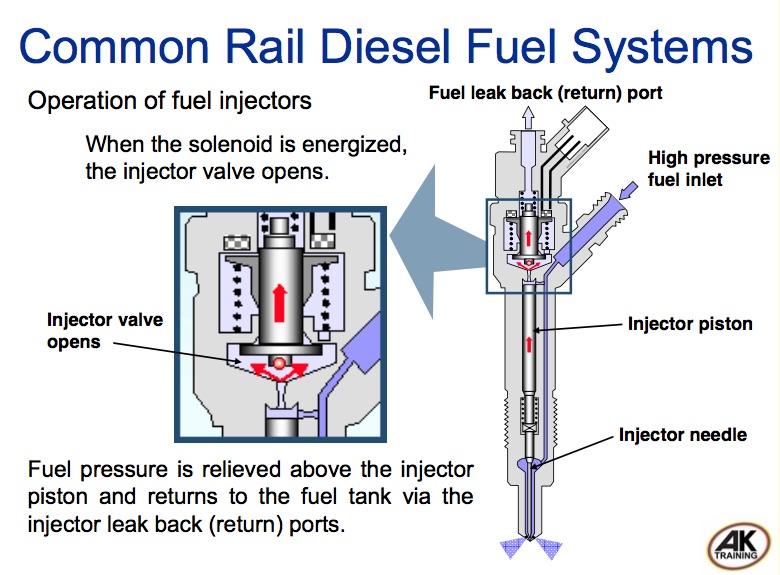

Five Fuel Events That Happen In Common Rail Direct Injection

Common rail injection for mid-size trucks has been around for nearly 15 years. While many owners appreciate the quietness and dependability of their diesel engines, many have no clue as to what changes have taken place to the fuel system in order to not only make their diesel perform, but also be emissions-compliant.

Understanding the Mack MP8

The Mack MP8 13-liter engine at first glance seems to be very similar to any other modern day diesel power plant. It uses the standard emissions devices including the EGR system, DOC (Diesel Oxidation Catalyst), DPF (Diesel Particulate Filter), electronic injection and VGT (Variable Geometric Turbo). But, behind the scenes are some interesting details that make the engine unique.

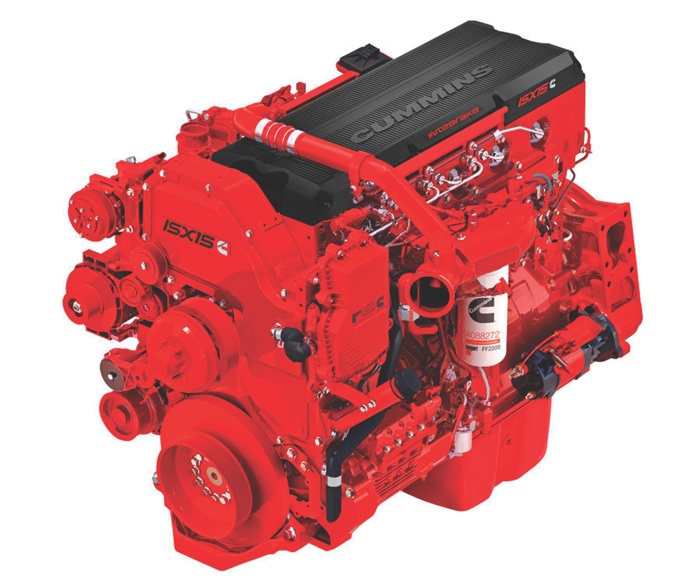

Cummins Powered ’07 Ford on the Dyno

Cummins-powered 2007 Ford does a dyno run with nitrous to see if it can break 1200 hp.

Performance Diesel Upgrades

Why should you offer more when rebuilding a diesel engine? Because any shop can rebuild the OEM block or buy a direct replacement. However, rebuilding a diesel engine with slight power modifications will get you more customers and offer you higher profits because of the modifications made that not everyone can do or has the knowledge to do.

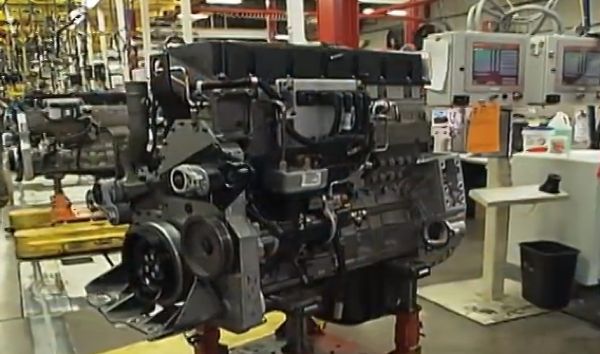

Inside the Cummins Heavy-Duty Engine Plant

Take a look inside the Cummins Heavy Duty Engine Plant in Jamestown, NY. See the production process and machining of Cummins heavy duty diesel engines.

Why Diesels Have Become ‘Greener’ and How You Can Benefit

For several years now, clean air and better fuel economy have been the primary focus of the transportation industry. Back in the 1970s, the clean air agenda came into full swing and it literally crippled performance as well as reliability. At that time, the diesel industry wasn’t being regulated by any of these emissions standards, but changes were on the horizon.

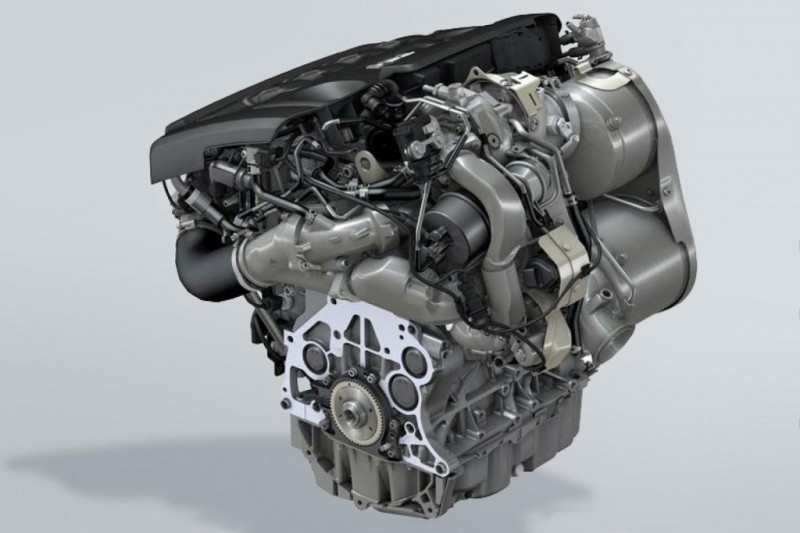

VW’s New 2.0L Diesel Will Bring New Engine Tech to U.S. – Eventually

As a rejuvenation of the current VW 2.0L diesel found in the non-U.S. Passat, the new engine adds several salient new features and upgrades. Variable valve timing is a new feature, and so is a special start-stop system, which shuts off the engine in the event the car’s speed falls below 7 mph.

Cavitation Erosion in Diesel Cylinders

Cavitation erosion is often found in diesel engines on the exterior walls of wet cylinder liners. The amount of erosion and decay will vary from engine to engine and may also vary from cylinder to cylinder.

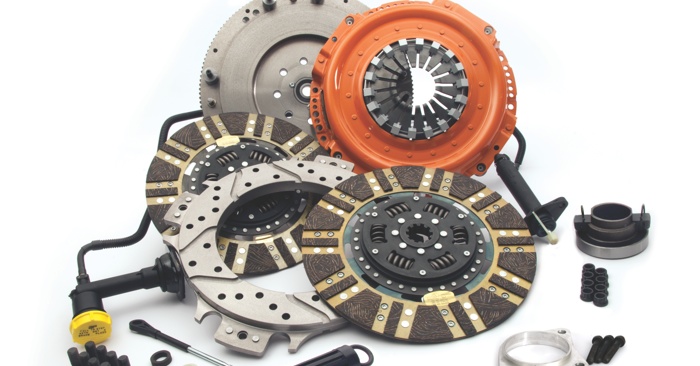

Centerforce 1,700 lb. ft. Rated Diesel Twin Clutch for Cummins-equipped Rams

The Centerforce Diesel Twin uses two sprung hub discs with a patented floater design that uses spring-loaded bushings to absorb typical “floater rattle.” The floater is drilled and slotted like a brake rotor to dissipate heat. This configuration helps to retain stock-like drivability. Smooth engagement comes from the two-stage sprung hub friction discs.