GROB Systems’ G550 5-Axis Universal Machining Center

The G550 is controlled by the powerful GROB4Pilot machine control panel, which offers a multi-functional user interface that provides machine operators with a convenient working environment.

Romi DCM 620-5X Hybrid Vertical Machining Center

The DCM 620-5X Hybrid is one of Romi’s complete line of hybrid manufacturing machine tools that combine traditional machining operations with 3D metallic additive manufacturing.

Equipment & Machine Maintenance

If you take care of your machines, they’ll take care of you.

Buying Machining Equipment

With the cost of some of these pieces of equipment equaling that of a house, it is crucial that engine builders and machine shop owners understand what options are available to them when looking to purchase new or used equipment.

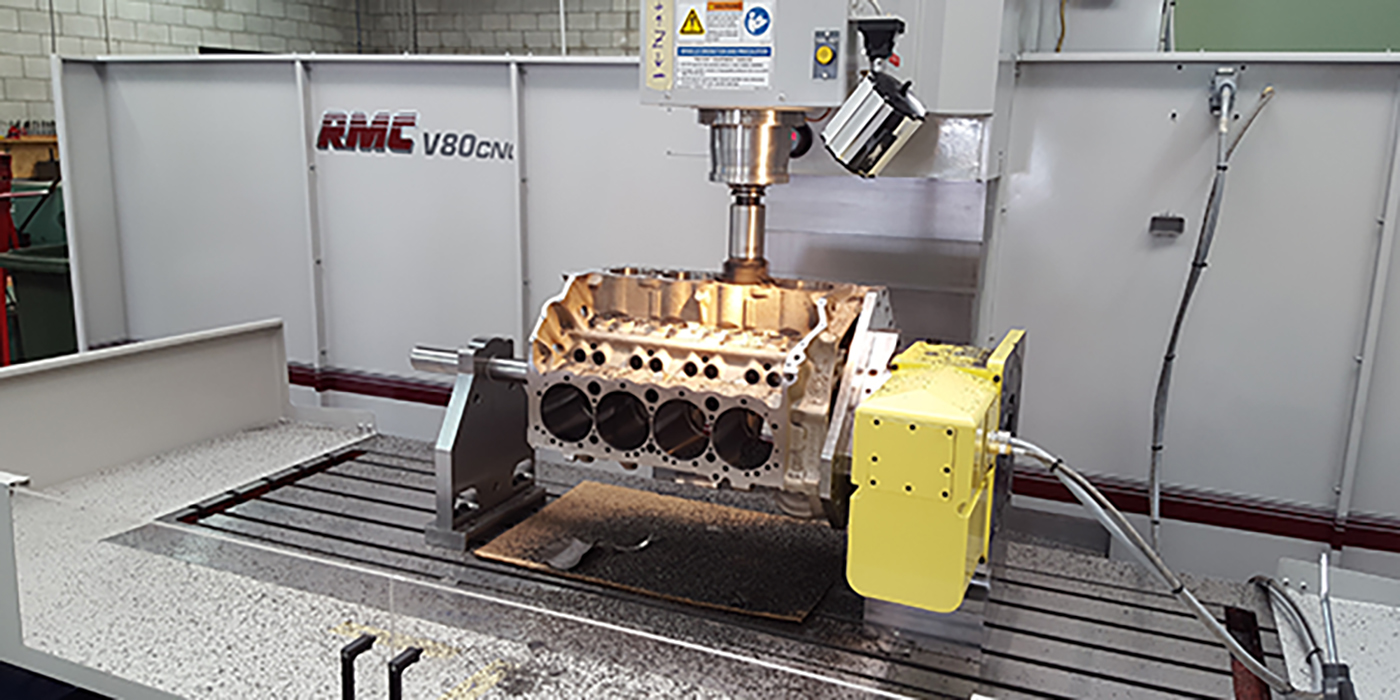

Machining for Other Industries

Modern CNC equipment and machining systems are capable of doing work on anything you can run a program for. Some shops have started to find additional uses for these machines.

Methods 5-Axis Bridge-Type Machining Center

Each machine is made to Methods’ design and engineering standards and is fully backed by Methods industry-leading service and support.

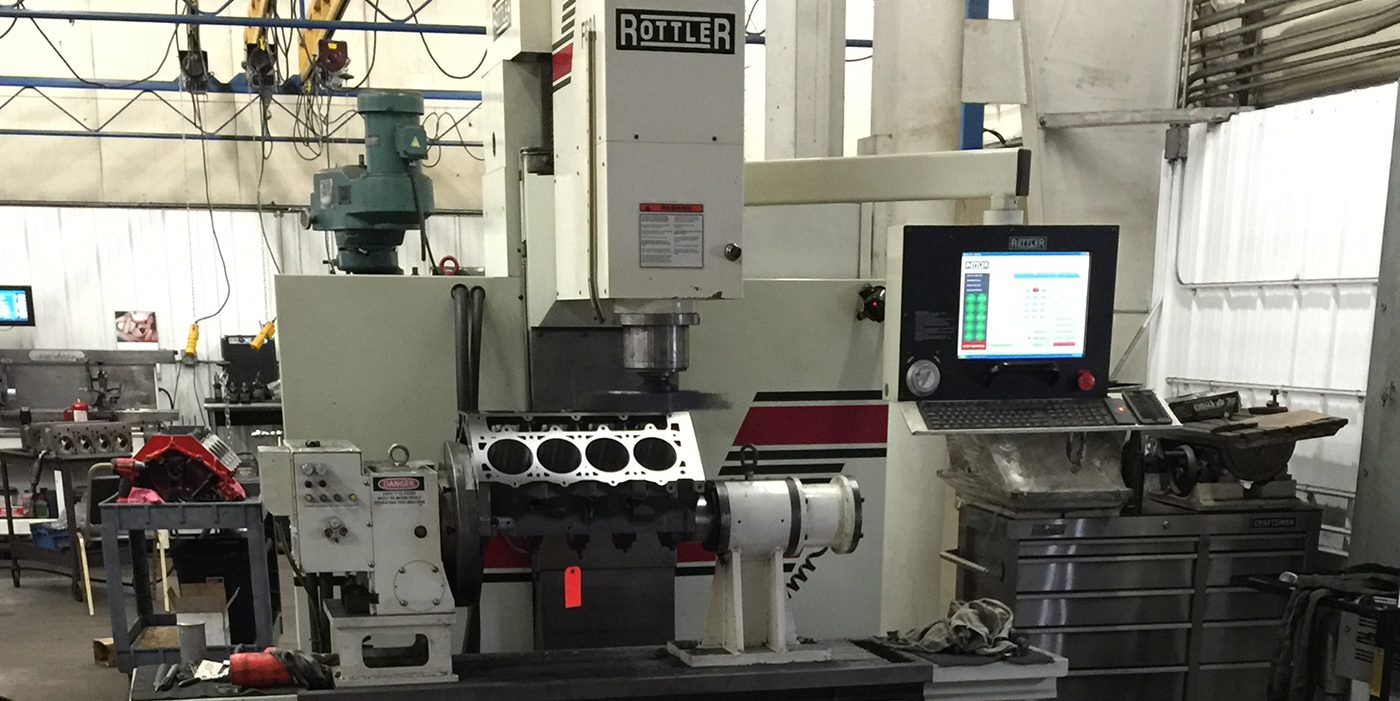

Boring & Honing in the Digital Age

Engine builders have as many preferences for the way they machine and build their engines as a baker does for making dough.

Methods Machine Tools Vertical Machining Centers

Methods Machine Tools, Inc., a supplier of precision machine tools and automation, has introduced a new line of Methods Branded 3-Axis Vertical and 5-Axis Bridge Type Machining Centers.

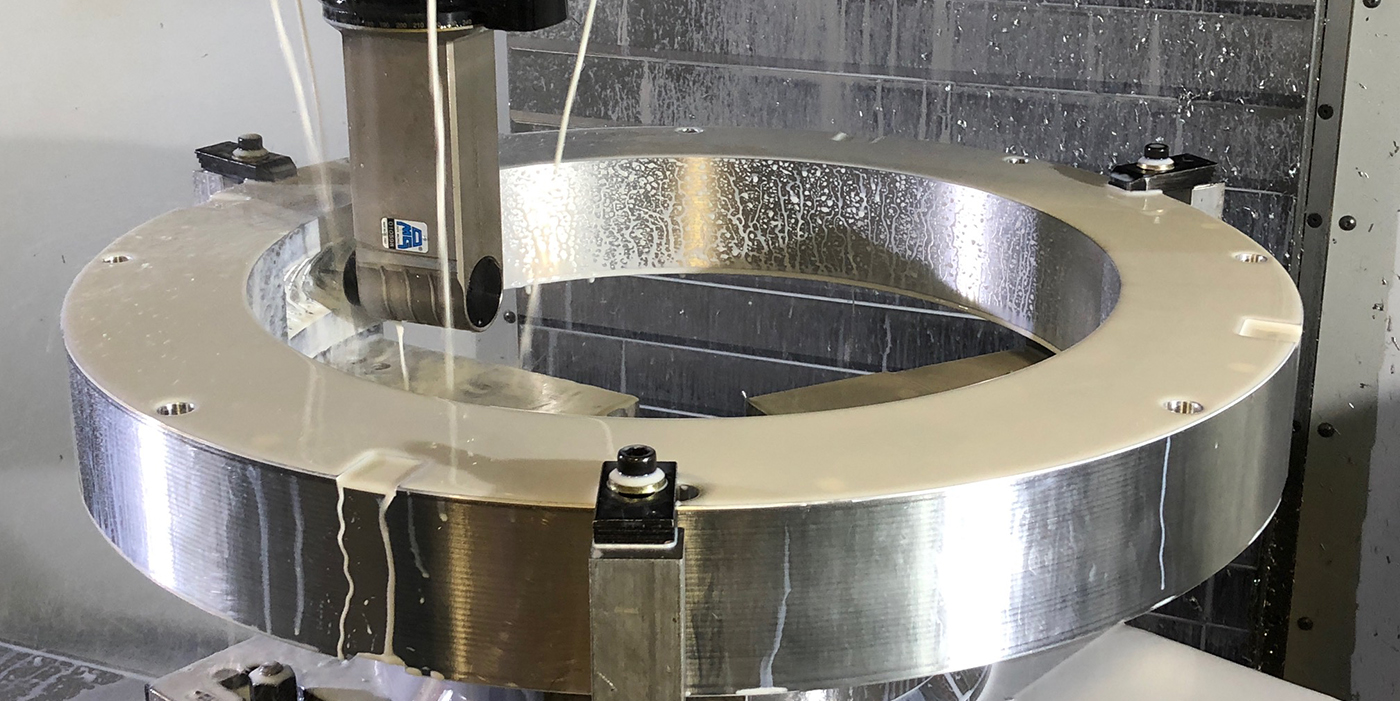

Surfacing Equipment For Today’s Engine Shops

Your shop owns many thousands of dollars worth of machining equipment, but if the newest one is more than a dozen years old, is it still up to the task for the jobs today? Looking back on some of Engine Builder’s past articles on surfacing equipment, one thing you’ll notice is that the OEMs have

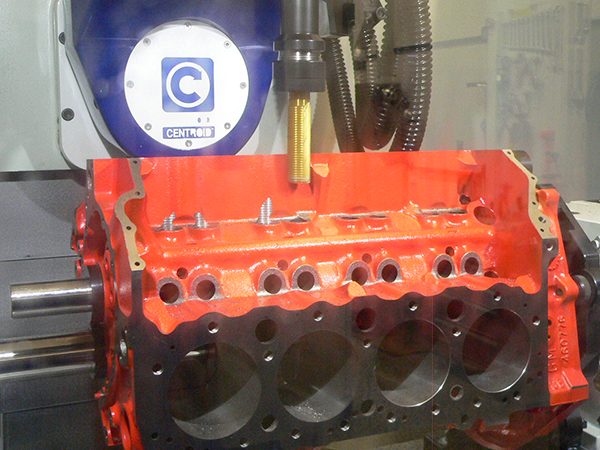

Learning Curve – Understanding the Evolution of Cylinder Head Seat and Guide Machines

Like many of you, I’ve been watching the transition in head machines for the engine machinist industry with great interest. And you and I both are looking at how changes in equipment will impact your business. You see, I teach in an engine machinist program and when I took over the program in 1993 our

Head & Block RESURFACING EQUIPMENT

Regardless of what type of engine work you do in your shop (stock, performance, diesel, marine or anything that comes in the door), you need the ability to surface heads and blocks. Deck surfaces on high mileage heads and blocks are often corroded, pitted, scratched and/or out-of-flat – especially if the engine blew a head