Tips for making the right deal for your shop

For many of you in the engine rebuilding industry, having access to the proper machines and equipment is the missing piece to creating the best engines possible for your customers. While you may get by with the machines or pieces of equipment you have now, you’re probably dreaming of what could be.

You might need a piece of machinery you currently don’t own to start doing work you’ve been farming out to another shop. Maybe you need to upgrade an existing piece of equipment because it no longer holds the necessary tolerances? You might even be looking at a used piece of equipment to add to the shop.

With the cost of some of these pieces of equipment equaling that of a house, it is crucial that engine builders and machine shop owners understand what options are available to them when looking to purchase new or used equipment, and the best ways to go about spending that much money.

Cash is King

Nobody wants another payment, but one of the biggest pitfalls is taking every last dime of your available working capital to pay cash for new equipment to avoid a monthly payment. If something happens six or nine months down the road and you’re strapped for cash, you’ll be in some trouble without any working capital to fall back on.

It may seem counterintuitive to want another monthly payment, but business-wise it makes more sense to finance income-producing equipment, let the work from that equipment help pay the monthly payment, and save the working capital and extra cash for situations you might really need it.

When looking to purchase a new machine, there is a happy medium when dealing with payment and financing. If an engine builder is looking at a $50,000 machine and he’s got $55,000 in the bank and wants to pay for it in cash, there are, perhaps, better ways to buy that machine than spending all your money.

Why not put 50% down, finance the other $25,000, enjoy the tax write-off and you’ll still have $30,000 of working capital in the bank should something else come up. If you have extra money, you may be better served putting it into inventory or something else that will make you a better return than paying interest.

On the other end of the spectrum, there are shops that don’t have much money, but need a machine to increase business or keep up with business. That’s actually a good sign for not only our industry, but the economy as a whole.

That tells us guys want to venture out on their own. They may not have the money or may not have the experience, but we are seeing more and more guys who work in a shop who want to start their own based on new business credit applications.

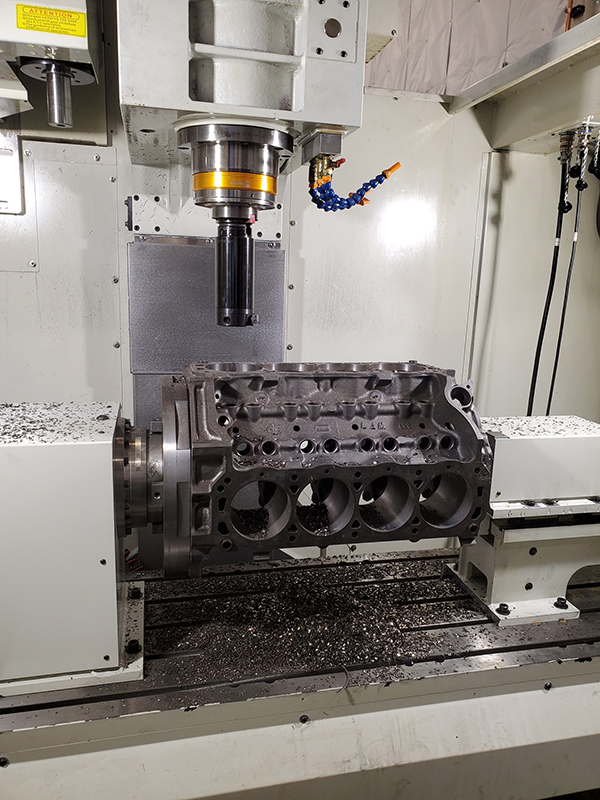

With the demands for more horsepower and performance coming from customers, and the technology advancements in today’s equipment, machine shops have to be able to keep up, not only for quality control, but the time involved. The difference from 20 years ago to today with a surfacer, balancer, seat and guide machine, CNC centers, and more, is night and day. With technology being what it is, the turnover in equipment is more so than it used to be. The return on the investment is also much greater than it used to be.

If you’re looking to finance your new equipment purchase(s), typically 5-7-year terms are available with a minimum, upfront, down payment.

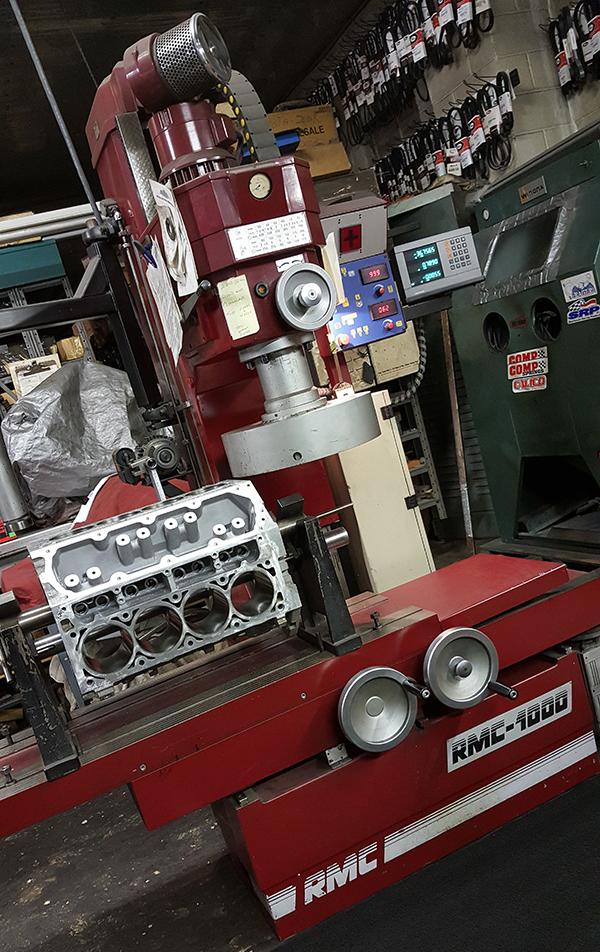

New vs. Used

Another route often taken by many people is finding a good, used piece of equipment rather than spending a small fortune on brand new equipment. These purchases can also be financed.

To most lenders, it makes no difference whether it’s a new piece of equipment or used piece of equipment, as long as the borrower is credit worthy. The only caveat is if it’s a really old piece of equipment, sometimes those purchases require shorter financing versus the usual five years.

While used equipment can be a great way to go depending on what kind of equipment it is, there are upsides and downsides to used versus new equipment.

If the price difference is small, it’s recommended you go new. You get the latest technology, the best warranty and you know exactly what you’re getting with no surprises. In this industry, equipment holds its value and 99 percent of the machine manufacturers back up what they sell.

Do your homework for used or rebuilt machines. Compare the price against known values for similar listed rebuilt equipment and compare it to a brand-new machine. Ask about any warranty. Ask what tooling is included in the purchase price. Get a list of the rebuilding procedure. Find out the exact year, make and model of the machine. Call the original manufacturer to make sure spare parts will continue to be available. Make an appointment to run the machine. Ask about loading, delivery and unloading. And, have your financing all lined up before you arrive.

If you’re looking at used machines, these are generally sold as is and where is. This machine will not have anything rebuilt and the tooling may be compromised or missing altogether. Yes, the used machine may have an attractive price, but be very cautious, and if you cannot run it first, then it’s better to stay away. Same rules apply here as they did for rebuilt machines.

You need to understand, if new machines are available then there will be used and rebuilt machines available. Just ensure you do your due diligence and if you shop wisely maybe you can find the next great machine your shop needs.

However, there’s often little replacement for stepping up and buying the new machine. Buying a brand-new machine has all the advantages you will need to stay up on the ever-changing world of today’s engine rebuilding procedures. New machines will always deliver the latest abilities to hold tolerances, newest features, redesigned tooling and holding fixtures, a full warranty, set up and training included, support from the manufacturer/sales rep, potential upgrades, and a long life.

Again, we want to stress the importance of keeping cash on hand. If paying off a machine purchase means using the last of your available cash, our advice is to not do it and hang on to that cash in case the unforeseen happens. You can also put that money into inventory, another piece of equipment, or even expand your business into things like a dynamometer.

And, speaking of dynamometers, the most popular pieces of equipment to finance are dynos, CNC machines and anything automated. With technology these days, there’s been a greater uptick in those kinds of machines and it’s another sign that the industry is healthy.

CNC Machines

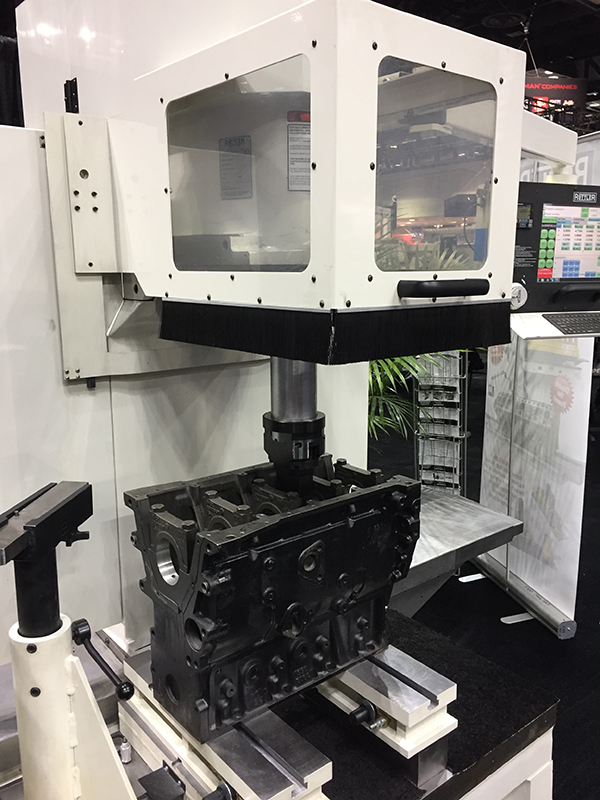

Thinking about buying a CNC machine? Some people think the way to make the plunge into CNC is to start small and work your way up from there. Buy a basic CNC machine that can do a certain job such as boring, honing, surfacing, etc., then buy a more capable CNC machine with more bells and whistles later on if the need arises.

The question you have to ask yourself is this – is a basic CNC machine all you will ever need, or could you use the additional features and capabilities of a more advanced machine to expand your business? It all depends on your business plan and the realistic potential for growth. Wishful thinking is not a business plan, but if you think you can offer something your competitors don’t, maybe that machine purchase is an opportunity to win over new customers and expand your business.

Some CNC machines are available with a “modular” or “adaptable” platform. This means you can purchase options in stages to match your current needs or budget. The basic machine can be a 3, 4, or 5-axis machine and accept the same fixturing, tooling and programming. The only differences would be in the machine travels, overall machine capacity, chip handling, different coolant dispensing options, enclosures, tool changers, speed, and horsepower. Obviously, you have to size the equipment to the type of engine work you do.

One machine that does a variety of jobs can certainly eliminate the need for several different machines while saving valuable floor space. On the other hand, if a job is in process and the CNC machine is tied up until the job is finished, it may become a bottleneck if you have other jobs waiting their turn in the machine. If floor space is not an issue, many shops will have both a multi-purpose CNC machining center as well as individual machines (CNC or manual) for certain dedicated tasks.

The cost of CNC equipment depends on its capabilities and features. How much bang you get for your buck will depend on what you buy. You can spend $60,000 or less on a basic CNC machine, or as much as $300,000 or more for a high-end, 5-axis, fully automated CNC machining center. Basic tooling is usually included, but additional tooling and fixturing may be needed depending on what you want to do.

According to CNC suppliers, about 80 percent of CNC equipment is financed. The rest is leased (5-7-year terms most commonly). Purchases and lease payments are also eligible tax write-offs, so don’t forget to figure those numbers in when calculating your ROI.

Where to Buy Equipment?

First and foremost, from a machine/equipment manufacturer and/or the sales rep. You can go this route for new or used equipment, and remember, price should never be your deciding factor when purchasing a piece of equipment. You need to look at the specs of the machine and determine whether or not an investment of this particular machine produces the work you want and a viable ROI.

You might ask, “Why do I need a sales representative just to buy a piece of equipment?” There are several reasons: They’re highly trained; They have automotive and machining backgrounds; They understand your business; They know and work with various finance companies; They provide set up and training; They are your go-to for follow up questions and support; They can deal with warranty issues; and, they want you to be successful.

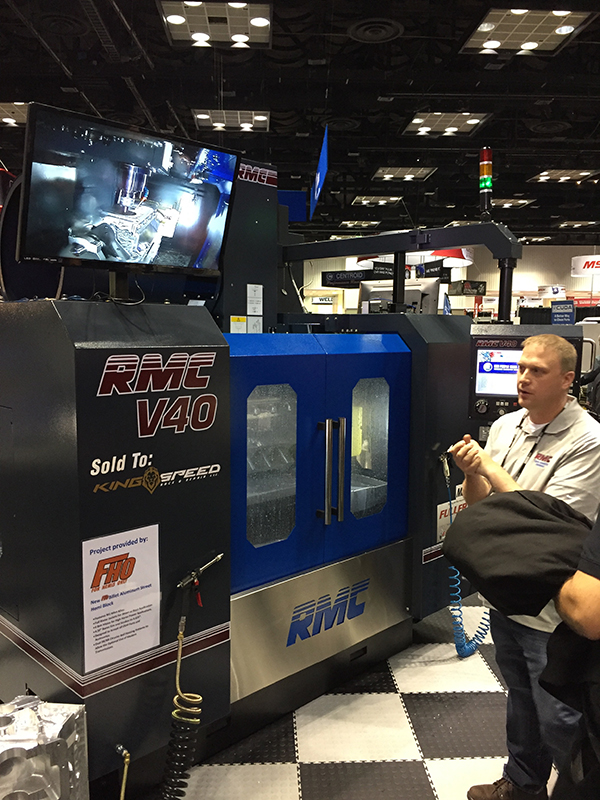

Outside of a sales rep and the manufacturer of the equipment, where can you go to find these machines? eBay? Classified ads? Auctions? Trade shows? All very good questions indeed.

Online auctions such as eBay should be approached with caution. You only get to see what the seller wishes you to see. It can be very difficult to understand the use or abuse the machine may have seen. Prices are at times very attractive (cheap) and also can be very out-of-market as well. Most of the time, you’re dealing with someone who may or may not know much about the machines. Buyer beware, especially if you cannot actually see the machine work. If a deal seems too good to be true, it probably is.

Classified ads, while “old school,” are usually better as most of these ads are placed directly from the machine shop selling the equipment and most still have them hooked up so you can go see and run the machine. Plus, you will be able to look the guy right in the eye to better understand the history and maintenance schedule. You’ll also get to see how well he takes care of the rest of the machines in his shop.

Auctions are an area where you need to be on top of your game. Auctioned machines will have no warranty, no tooling guarantees, and yes, during the bidding frenzy you can actually pay more than you would for a brand-new machine. Do your homework and research before you go, and know your spending limits and keep to them. Auctions can be a real bargain or a real nightmare.

Another spot to look for equipment is on social media. Many manufacturers and shops alike will now use sites like Facebook and Instagram to spread the word about equipment deals. As with eBay and classifieds, just make sure you’re doing your due diligence before you pull the trigger.

Trade shows are one of the best places to shop for your new machines. At nearly every trade show the equipment is hooked up and running. Equipment manufacturers have their best techs doing demonstrations and they can answer your questions right there. You can also run the machine yourself to see if it is what you and your shop are looking for. You have the ability to overhear other questions from shop owners just like you and they can provide financing if needed right there on the spot. That is, once trade shows return again. EB