Kaase Boss Nine Engine

The Boss 429 was a NASCAR special back in 1969 Mustangs and the Ford faithful have been lusting for the Blue Crescent/Shotgun engines ever since. While others dreamed, the die-hard Ford junkies at Jon Kaase Racing Engines worked, and brought the Boss 429 back to life in the form of the Kaase Boss Nine engine.

347 Small Block Ford Engine

Mike Consolo of QMP Racing Engines spent more than four and a half years rebuilding this 347 small block Ford for a customer’s road racing Sunbeam Tiger. All said and done, the engine puts out 625 hp and is race ready once again.

S&S-Based Harley-Davidson Evolution V-Twin Engine

A customer in Toronto recently turned to Gregg Dahl and GMS Racing Engines for a Fast Bracket Racing drag bike engine. Dahl answered the call as those engines are his specialty. The result was this 200 hp S&S-based Harley-Davidson Evolution V-Twin engine.

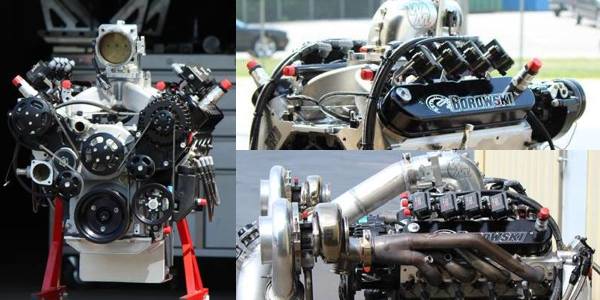

427 Twin-Turbo LS Engine

Ken McCaul of Borowski Race Engines built this hydraulic cam 427 twin-turbo engine with All Pro heads and Cometic MLX gaskets. It makes 1,530 hp on C16 fuel and features twin Bullseye turbochargers.

David Vizard to Present Performance Engine Seminar in Elyria, OH, Charlotte, NC

Internationally recognized author, engineer, racer and lecturer David Vizard will present an intimate Engine Performance Seminar May 5-7 at Motorhead’s in Elyria, OH. “This in-depth seminar focuses on informing the professional running a typical small shop (1 to 10 employees) of techniques and methods to get more power from their builds for (as often as

426 Chrysler HEMI Engine

Right now Ray Barton has 70 426 Chrysler HEMI engines sitting in his shop. In fact, Ray Barton Racing Engines, is world famous for these engines. From rebuilds to dyno services and valve train analyzing to cylinder head work, find out why his HEMIs are in demand.

Racing Rods – Engine Builders Have Options

Choosing a set of connecting rods is one of the critical steps in a performance engine build. The rods have to be strong enough to handle the anticipated speeds and loads, but also affordable for customers who have a limited budget. Most stock rods in late model engines can safely handle 400 to 500 horsepower.

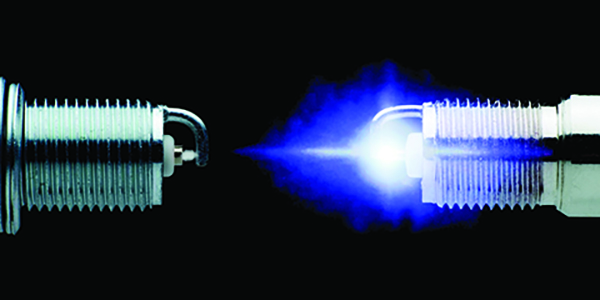

Racing Spark Plugs

Choosing a set of racing spark plugs for a particular application is not as easy as it sounds because the plugs have to be closely matched to the application. Stock plugs are fine for stock applications and ordinary driving conditions. But when an engine is modified to make more power and is run under racing

To The Victor Go The Spoils – Victory Engines

Ray Banyas was given two weeks to decide if he wanted to buy Myles Engineering and go from long-time employee to owner of the Cleveland-based engine shop. The alternative? The business would shut down after being open 70 years. “A friend of mine said, ‘You might as well try it. You’ll kick yourself if you

Wet & Dry Sump Oiling Systems – Choosing the Right System for the Right Job

If you are building a customer’s “dream engine” what type of oiling system should you use? The answer to that question will depend on the application (street, drag, circle track, road race, off-road or marine), engine RPM and how much your customer is willing to invest in a lubrication system. Your choices may also be

Midget Engines – Perfect Power from Pint-Size Performers

Midget open-wheel racecars and the Stock (S Class) and Modified (A Class) inboard hydroplanes have provided thrills and chills for racing fans since the 1930s. And as the speed and performance of these radically-different racing machines has improved, so have the engines that power them. These engines have varied from stock four and six-cylinder automotive-type

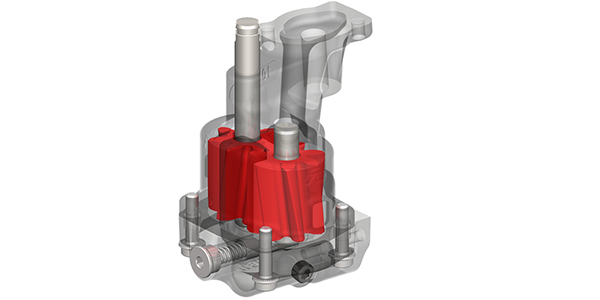

The Science Behind Wet Sump Oil Pumps & Oiling System Upgrades

All automotive internal combustion engines are equipped with some type of pressurized oiling system. Oil lubrication is essential for reducing friction, preventing wear and cooling vital engine components. Pumping oil to the main and rod bearings creates a friction-reducing hydrodynamic film between the bearings and crank that allows the crank to spin with minimal friction.