The timing components that drive a camshaft affect valve timing, ignition timing (if the engine has a cam-driven distributor), compression, engine performance and fuel economy. Because of this, the timing components must be in good condition with minimal wear and slop, and they must be durable enough to maintain accurate timing for the service life of the engine.

The timing components that drive a camshaft affect valve timing, ignition timing (if the engine has a cam-driven distributor), compression, engine performance and fuel economy. Because of this, the timing components must be in good condition with minimal wear and slop, and they must be durable enough to maintain accurate timing for the service life of the engine.

Camshafts rotate at half the speed of the crankshaft in four-stroke engines, so there is always a two-to-one gear ratio between the timing components that connect the crank and cam. The cam drive may be a chain and sprockets, a belt and sprockets, a gear drive, or a combination of any of these such as Chevy’s 3.4L DOHC V6 that uses a timing belt to drive the cams and a chain to drive the intermediate sprocket that drives the belt. Any type of cam drive is capable of doing the job, but there are advantages and disadvantages with each type.

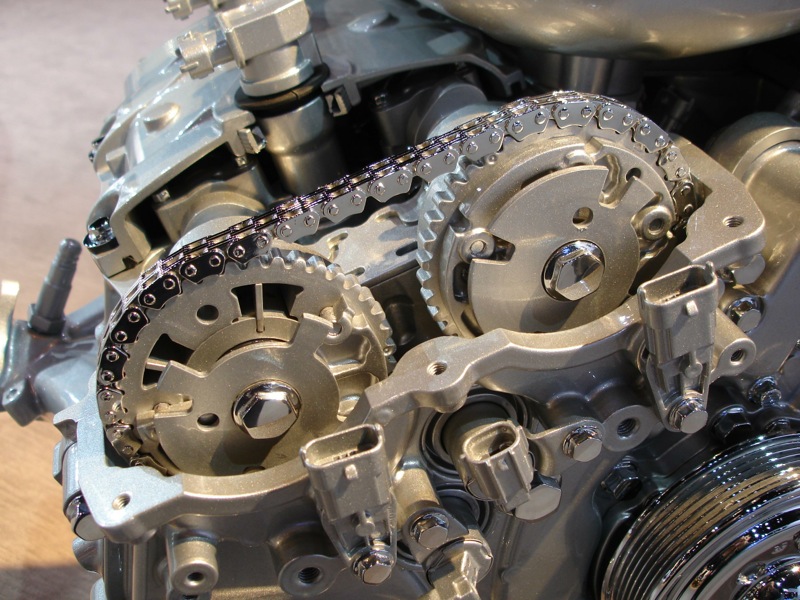

Timing chains are reliable and can be used in pushrod engines or overhead cam engines. A chain is usually quieter than a straight cut gear set but not as quiet as a belt.

Chains are usually less expensive than gears but more expensive than belts. Their downside is that they stretch, which typically occurs after many miles of service but can happen fairly early in the chain’s life in a high-performance engine with high valve spring pressures. Chain stretch is not good because it creates slop, noise and retards valve timing and ignition timing. Chain rattle is a common complaint in high mileage pushrod engines when the chain has stretched and is rubbing against the timing cover. Chain rattle can also occur in OHC engines as a result of stretching, but is often caused by worn or damaged chain guides or a bad chain tensioner.

Timing belts have been used on a wide variety of OHC cam engines over the years. Timing belts are quiet, and they generate less friction than a timing chain or gear drive, which reduces parasitic horsepower losses inside the engine and improves fuel economy and power. Timing belts may be made of synthetic rubber such as neoprene, Highly Saturated Nitrile (HSN) or EPDM, and reinforced with tough fiber cords (often Kevlar). The tensile cords inside a timing belt prevent it from stretching, which allows a belt to maintain accurate valve timing for a longer period of time than a chain typically would. But belt life is limited by the material the belt is made from. On older applications (1990s vintage and earlier), the recommended replacement interval for OHC timing belts was typically 60,000 miles. Today, it ranges from 100,000 to 120,000 miles thanks to belts constructed of stronger and more durable materials.

Timing belts will often last much longer than the recommended replacement interval, but they won’t last forever. Eventually, the belt will fail — usually with little or no warning — and when that happens, it can bend the valves and cause a lot of expensive damage if the application is an interference engine.

To go the distance, a timing belt must be properly tensioned and protected from outside contaminants (no missing dust covers and no oil or grease contamination from engine oil leaks). If belt tension is not adjusted properly when the belt is installed, or the belt loosens up, it can jump time. It can also jump time if the cogs on the underside of the belt are worn or damaged.

Gear drives are the most robust type of cam drive because there’s no chain stretch or belt breakage to worry about. That’s why a lot of diesel engines use gears to drive the cam instead of a timing chain.

Gears are long lived but will wear over time. It’s important to make sure the gears have the proper backlash and receive adequate lubrication. The initial timing accuracy of a gear drive is no different than that of a new chain or belt drive. The only difference is that the gears should maintain timing accuracy over a longer period of time than a chain.

The downside of a gear drive is that they are more expensive than most chain or belt drives, and heavier. Straight cut gears can be quite noisy (even the so-called “silent” versions), producing a loud whine as the teeth mesh against each other. Most OEM gear drives have more expensive helical cut gears that are machined at an angle to reduce friction and noise.

Because a gear drive has less “give” than a timing chain or belt, gears also tend to transmit more vibration and harmonics to the valvetrain. In low RPM engines (such as diesels), this usually isn’t an issue.

But in a high-revving performance engine with a gear drive setup, it may create harmonics that affect valve timing and valve seating. Some manufacturers of aftermarket performance gear drives that use a dog-bone style floating gear set between the cam and crank gears do not recommend using their products on engines that rev higher than 7,000 RPM.

Stocking Up

Stock timing components are usually fine for stock applications, so most aftermarket replacement parts are OEM-equivalent in design and the type of materials used. In situations where the OEM parts have had a history of premature wear or failure (such as composite nylon-filled plastic timing gears used with chains), upgrading to a timing set that includes redesigned and/or stronger components such as steel or powder metal gears may improve durability and reduce the risk of cam drive problems down the road.

If you’re building a performance pushrod V8 engine with a hotter cam and stiffer valve springs, it goes without saying that the stock timing components are probably not up to the task. You should replace the stock inverted silent tooth or single row timing chain with a stronger double row roller chain. A double roller chain is usually recommended for engine speeds above 6000 RPM. Billet steel gears are also recommended for engines that are upwards of 600 or 700 horsepower or use heavy (over 200 pounds of closed seat pressure) valve springs.

The aftermarket offers a lot of options when it comes to cam drives, and each of the various approaches has their supporters and detractors. Many racers replace a timing chain with a gear drive conversion because they want the increased strength and durability of a gear set. Some like the gear whine because it makes people wonder what you have under the hood (a blower maybe?). Others hate the noise of a gear drive and prefer to stick with a double roller chain setup. The more exotic the setup, the higher the cost. Many ProStock drag racers use a high performance belt drive setup and have great success with it. Others are leery of belts for fear they will break so they stick with a gear drive or double roller chain.

One of the advantages of a belt drive is easy adjustability. Unlike a timing chain or gear set, a belt drive requires no lubrication so it doesn’t have to be sealed up behind a timing cover. This makes cam timing adjustments much easier, as well as belt inspections. If a belt drive is being used on the street, off-road or on a dirt track, a dust cover should be used to protect the belt.

Converting to a high-performance belt drive does require some minor modifications such as installing a front cover seal plate and oil seals behind the crank and cam sprockets to seal the engine. The front plate that typically comes with a belt drive kit is machined to fit specific block applications, including standard blocks and aftermarket blocks with a raised cam bore. The more complex the cover, the higher the cost of the kit. Some belt kits are available with torrington bearings or even ball bearing thrust bearings for the cam to precisely control cam end-play.

Another advantage with belt drives is that they make it easy to use a front-mounted distributor. This gives you more flexibility in planning the overall configuration of the engine, and comes in handy if an engine will be equipped with a long supercharger that would otherwise interfere with the location of a stock distributor. The belt drive can also be used to drive a front-mounted fuel pump.

The trade-off with belts is that they are not as long lived as chain drives or gear drives in performance applications. The belt has a limited life, and should be replaced after a certain period of time depending on use. For drag racing, one recommendation is to replace the belt every 200 runs. For circle track racing, replacing the belt at the end of the season is recommended. For endurance racing, most racers will change the belt every race.

Time to Replace

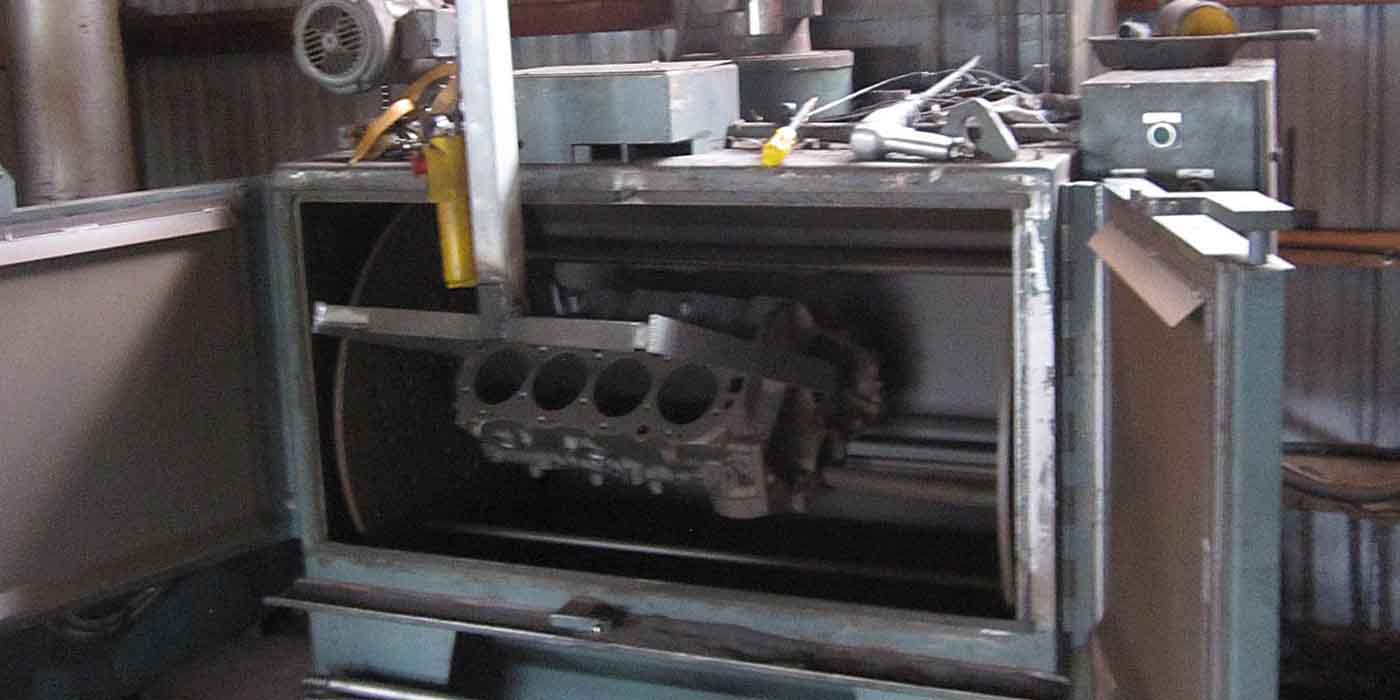

With a typical engine rebuild, the parts that have to be replaced generally depend on their condition. You replace wear components such as rings and bearings, and other components based on their condition. This includes the timing components, which should always be treated as a system. With a chain drive, the chain, crank and cam sprockets should always be replaced as a complete timing set. Installing a new chain on worn sprockets is not going to provide accurate cam timing or long-term reliability. The same goes for overhead cam engines with timing chains. The chain, guides, tensioners and other components should all be replaced at the same time.

It’s the same story with timing belts. Replace used high-mileage timing belts with a timing belt kit, not just the belt itself. Many timing belt kits include a new tensioner and/or idler pulley with the belt. Timing belt failures can be caused by a faulty belt tensioner or guide, or a bad sprocket. Idler pulley and tensioner pulley bearings are “sealed for life” and are not serviceable, so there’s no way to clean, inspect or re-lubricate the pulley bearings when a timing belt is changed. If a pulley is noisy, binding or wobbles, it needs to be replaced.

Another reason for installing a complete timing belt kit is that it reduces the risk of mismatched parts. Timing belts can have one of several different tooth profiles in addition to different lengths and widths. If there’s a mismatch between the belt and drive sprockets, tensioner or idler pulleys, it will ruin the belt.

Replacement belts must be the same as the original. Compare the old and new belts carefully to make sure the length, width and tooth profiles all match. The camshaft and crankshaft drive sprockets also need to be cleaned and inspected for wear or damage that could shorten the life of a new belt.

If you are doing the final assembly on an OHC engine with a timing belt, NEVER stretch a belt over a pulley or sprocket as this may damage the cords inside the belt. Also, do not twist or crimp a new timing belt when you are installing it.

If a timing belt does not seem to fit properly (and it is the correct belt for the application), there may be misalignment between the camshaft and/or crankshaft sprockets. A cam sprocket may have been installed backwards, the wrong thrust washer may have been used, or the crank sprocket may be too far in or out on the crank for proper alignment.

If you’re replacing a spring-loaded hydraulic chain tensioner on an OHC engine, note that the replacement tensioner may have a release pin that must be removed AFTER the tensioner has been installed on the engine. If this pin is not removed, the tensioner will not be able to expand and tighten the chain which will lead to premature failure and possible engine damage.

Also, make sure the replacement parts you get are the latest ones for the application. Check the latest factory service literature for any engine-related TSBs or bulletins that might include revised parts or installation procedures.

For example, older Ford 4.0L SOHC V6 engines often suffer from timing chain rattle. The teflon chain guides that were used in these engines wear and fail prematurely, causing the noise. Ford redesigned the cam chain tensioners and guides to fix the problem, so if you don’t get the improved replacement parts (or their aftermarket equivalent), the engine will have the same noise problem as before.

Something else to keep in mind is that all timing sets are not the same. Differences in price usually reflect differences in quality, materials and workmanship. A cheap timing chain set or timing belt from a no-name supplier may turn out to be no bargain at all if it doesn’t fit right or fails prematurely.

Cam Timing Notes

With a stock engine build, there’s usually no need to play around with valve timing other than to verify it is accurate. You line up the timing marks on the sprockets and chains, or count chain links between sprockets and follow the factory timing procedure to make sure cam timing is right on. Always double-check the alignment of the timing marks, and turn the engine over twice by hand to make sure nothing is binding and that the timing marks realign the same as before.

With a performance build, you may want to advance or retard cam timing depending on where you want the engine’s power curve to peak. Most aftermarket performance timing sets have an adjustable cam gear that can be installed in different index positions to provide up to 8-10 degrees of advance or retard in 2 degree increments. Offset dowel pins and keyways can also be used for the same purpose.

Never assume cam timing is correct even if the timing marks all line up perfectly. Use a degree wheel and dial indicator to check cam timing with the number one piston at Top Dead Center (TDC).

Once you’ve verified base timing, you can make additional adjustments from there. Most aftermarket street performance cams come with 4 degrees of initial advance already ground into the cam to help low RPM torque and drivability. If you want more or less timing advance, you need to verify what the timing actually is, then make any changes as needed to set the timing where you want it.