The relationship between the cam(s) and the crankshaft is like a marriage. You might say they are heavily dependent on each other for their survival because any slip-up and their union could end in catastrophe.

If you’re building late-model dual overhead cam (DOHC) engines, you’ve probably noticed that a chain rather than a belt drives the camshaft. But why is this the case when chains are more expensive to produce?

Cale Risinger from Melling Engine Parts believes it is due to the complexity of the newer, primarily V-style engines. “Most are DOHC, and many have an idler sprocket that transfers the crankshaft rotation to the two chains that drive the cams. I cannot imagine the amount of packaging space required to do this with belts. I’m not sure if the carbon footprint might also come into play, either in belt production or the waste of throwing the belt away every 50k. I would also think a vehicle that does not require an expensive service, such as a timing belt replacement every 50k, would be more appealing to customers.”

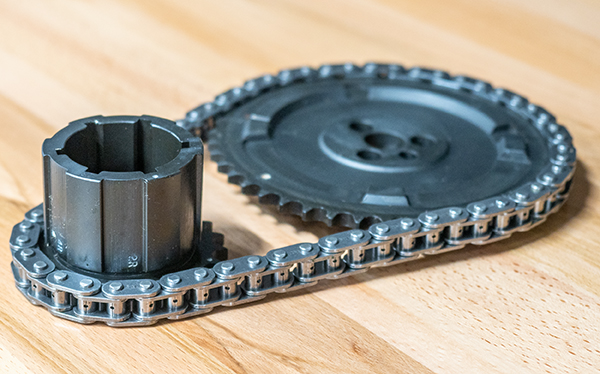

While timing belts have been steadily giving way to chains due to their longer service life, belt manufacturers have made strides to improve their belt life to more than 100,000 miles, in some cases. Even though belts will not last as long as a chain, they are quieter, create less friction, and often easier to line up with the cam and crank locked down.

“In most cases, if the engine is properly maintained, service intervals would be the main advantage to a chain over a belt,” says Risinger. “The chain is also, for lack of a better word, more durable. Thinking back to the days of timing belts, if the front crank seal leaked on an engine to the point of coating the belt, you would most likely find the belt nearly shredded when inspecting it due to the oil saturation. On a chain-driven timing set, you simply change the crank seal, clean up the mess from the oil leak and move on.”

Because modern vehicles use so many electronics to control the engine with crank and camshaft timing sensors, engine builders and technicians need to make sure the alignment of the timing chain is “dead-on” or, as some say, “dead-nuts.” The cam gear cannot be off by even a tooth, or the engine may set off an engine code or worse. The cam and crank must correlate to within a certain number of degrees set by the ECU, which could be less than 8 degrees in some vehicles. If the engine also has variable valve timing, it’s a little more challenging to be sure the cam is where it is supposed to be since the gear can move around on its axis and throw things off.

While OE timing components are available from the dealer and other channels, aftermarket suppliers such as Cloyes and Melling offer improved products for specific applications with known timing chain issues.

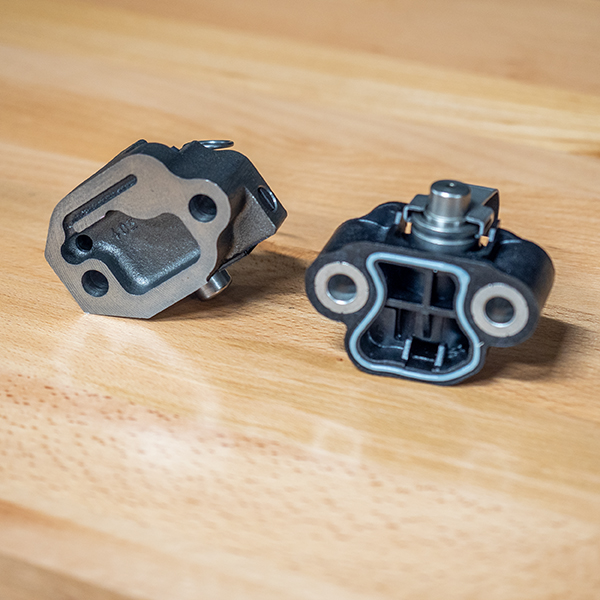

Risinger says one example would be the timing chain tensioners for the 5.4L modular V8 Ford engines. “The OE tensioners are plastic and have an integral seal. Over time the plastic breaks down and fractures which leads to seal failure, and ultimately timing failure. We have developed cast iron tensioners for these engines that don’t require a gasket. We have also incorporated a ratcheting mechanism that eliminates the possibility of a slack tensioner on startup due to oil bleed down.”

Slack in the system can cause the chain to ride up the sprocket and stretch or break it. Timing systems use hydraulic chain tensioners that are operated by using engine oil and oil pressure. Because of this, specific timing chain tensioner designs can present issues. The timing chain tensioner is essentially the heart of the timing system and is often overlooked. If proper tension isn’t maintained, the system will fail.

Another issue with timing chains is stretch, which is typically due to oil maintenance neglect. “The most common failure point seems to be chain stretch,” says Risinger. “I believe that this stretch is ultimately the result of lack of proper lubrication to the chain. This lack of lubrication directly correlates to proper vehicle maintenance.

Worn-out oil won’t lubricate the chain and cause the rollers and links to wear against each other. As the chain rotates around the gears on the camshafts and crankshaft, the movement between the rollers and links also causes wear and elongation.

Extended oil change intervals are not timing component friendly, says Risinger. “I think most drivers, including myself, got very used to changing their oil every 3k-5k miles. But most healthy engines will use little to no oil in that mileage interval, which in turn, got us out of the habit of regularly checking our oil level.”

With oil life monitoring systems pushed service intervals out 7k-10k miles combined with very light oil viscosities, Risinger says engines are using more oil during that interval, and drivers are still not checking their oil level. “I had a customer bring in a vehicle a few years back complaining of a rattling noise when making hard left-hand parking lot maneuver type turns. While test driving it, I noticed this noise sounded like timing chain noise. We found that the 6-quart capacity oil system had around a quart and a half of oil in it. When they made a parking lot maneuver, the oil ran away from the pickup, causing oil pressure to drop, which allowed the tensioners to lose tension. The chains then would slack, which caused the rattle noise. The sad thing was, this engine only had around 40k miles on it, and the oil life monitor still showed 20% engine oil life.”

Most OEMs don’t spec a replacement interval for their timing chains, which is why oil maintenance is so critical. However, when rebuilding a DOHC engine with a chain, you will want to replace most of the timing components, whether they are worn or not. In most cases, aftermarket kits from quality suppliers will offer the most coverage and solutions for problem applications.

Long-life oil is not necessarily a good idea on OHC engines with variable valve timing actuators because they rely on good clean oil to operate. Risinger says that oil maintenance is critical for VVT systems because the oil is fed through the camshaft to the actuator. “Lack of maintenance can lead to engine wear, which can increase the cam to journal clearances. This wear can, in turn, reduce the amount of oil volume supplied to the actuator.”

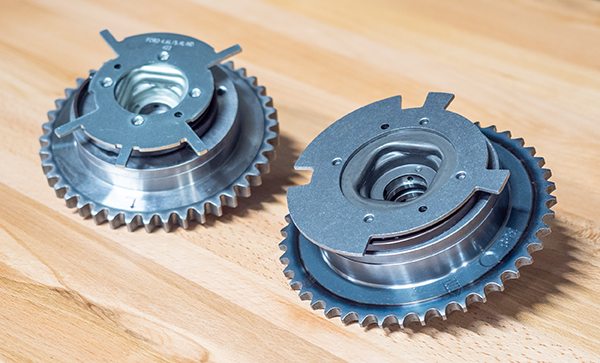

With many of the newer engines having direct injection, which we know causes increased soot, or turbos, which adds heat to the oil, more frequent oil changes are a must. “The lube paths to the actuators, and in the actuators themselves, are fairly small,” Risinger explains. “This dirty, deteriorated oil can cause these passages to plug and may also lead to internal actuator damage.”

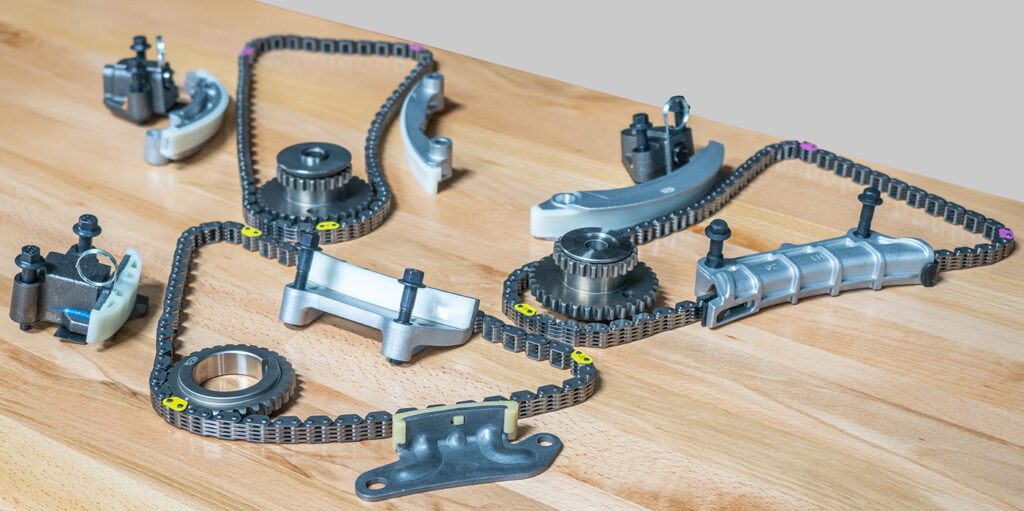

Some engines are better than others, and some are prone to oil consumption that can cause problems with the timing system. “Engines that are prone to oil consumption issues can easily be run low on oil, which will cause lack of lubrication to the chain and tensioners,” says Risinger. “Take the GM V6, 3.6L DOHC engine, for example. Like some bizarre math word problem, this DOHC, four-camshaft engine uses two idler sprockets requiring three separate timing chains to operate the timing system.

“There are four camshaft sensors and a crankshaft sensor used to operate the VVT system, etc. The front of the engine is shown below and includes 15-pieces needed to service this timing system – which doesn’t include any of the VVT components.”

As Risinger noted, late-model applications use multiple camshafts and balance shafts that need more sensor input to improve performance and reduce emissions. Sensors control VVT operation, but the oil is the lifeblood that advances or retards the timing. A check engine light is triggered if new timing components are not installed correctly. Each engine is a little bit different, so be sure to look at how it is all oriented before replacing.

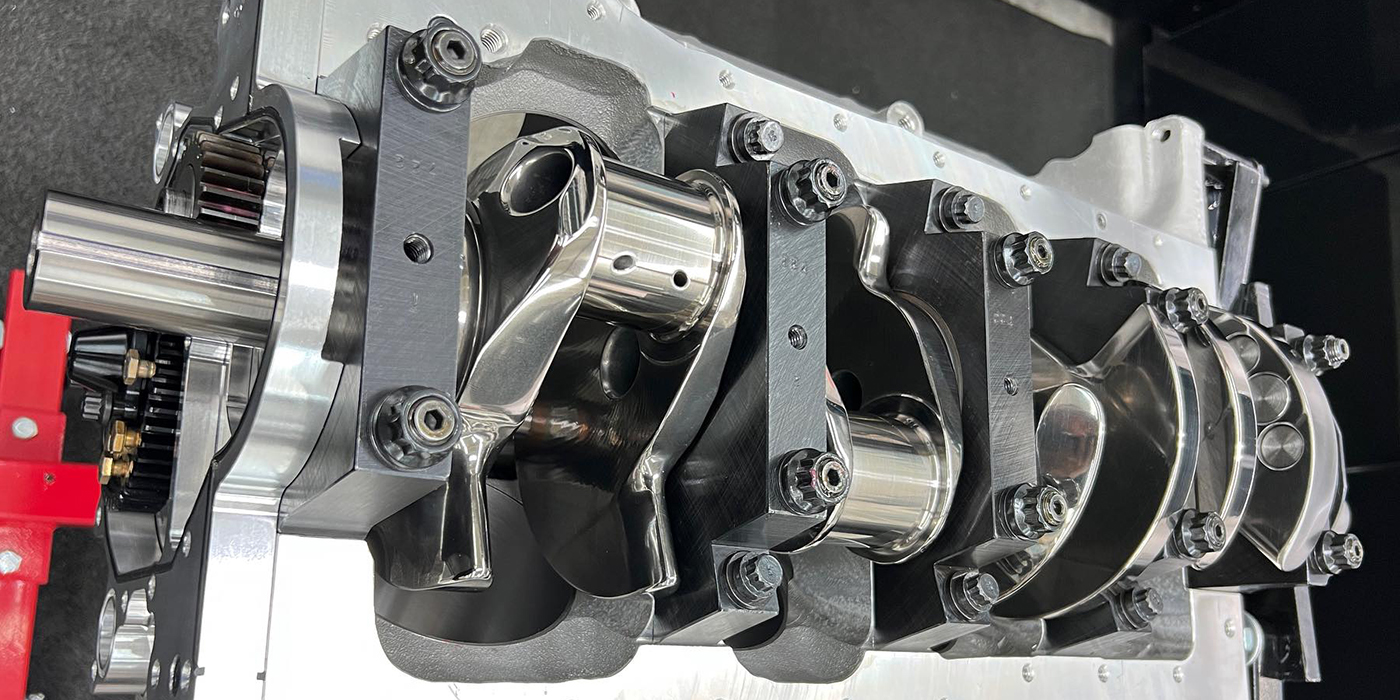

Overall, timing systems have become much more complex. As we have transitioned away three-piece sets in many late-model engines to overhead cams, there are now many configurations of timing sets that have incorporated VVT or even twin VVTs per head.

This extra rotating mass is more demanding on the chains. Variable valve timing loads the system dynamically as the valvetrain changes. The relative motion itself strains the system when the VVT is in operation.

All the timing chain systems depend heavily on good, clean oil to act as the hydraulic system to support the system’s stability. It puts more demand on the oiling system as you depend on the timing system to keep it all stable. And when it fails, it’s like a perfect storm.

In general, overhead cam engines will pose greater repair complexity. Indeed, newer engine designs will require specialized knowledge about timing. But, the OEMs are continuing to drive forward to come up with innovations. With direct injection and more turbocharged engines, the demand for stable and robust timing systems becomes even more significant. EB