Marine engine building is a niche market that is much smaller than the automotive market, but it can also be a very lucrative business for those with the know-how and experience. The type of engines we’re talking about are mostly big block Chevy-based high performance mills in some type of pleasure craft or offshore race boat. These are big buck motors that can cost $30,000 to $80,000 or more, and they are often sold in pairs! It definitely takes deep pockets to afford the high end marine engines.

Although the basic machine work required to build a marine engine is essentially the same as an automotive engine, that’s where the similarities end. Marine engines have an entirely different operating environment than automotive engines. They typically spend most of their time at cruise or full throttle. Cruising speed for a boat is a lot different than that for an automobile cruising down the highway. Cruising RPM for many of these marine engines is 3,500 to 4,000 RPM depending on the drive ratio and prop size. By comparison, a typical automotive engine will only be turning 1,600 to 2,000 rpm at highway speeds.

Full throttle is also different. It’s truly full throttle all the way – maybe 5,500 to 7,500 RPM for long periods of time (possibly hours!), which puts a lot of stress on an engine and its internals. Most street performance, circle track and road race engines, by comparison, only see peak RPMs in short bursts, and are constantly changing RPM as the driver is on and off the throttle. Most passenger car engines rarely see the high side of 4,500 RPM, and spend most of their time idling or loading along at relatively low RPMs. With drag race and tractor pull motors, full throttle only lasts for a matter of seconds until the throttle snaps shut and the engine comes back down to idle.

Another important difference between boats and cars is that boats don’t coast. The motor is always pushing the boat forward. There’s no backing up and a boat can’t use the engine for braking. If an inexperienced driver is running full throttle and suddenly lets off on the throttle, a small boat can nose dive and may even flip end over end!

The strain of running under constant load and high RPM means marine engines have to be built tough – really tough. That means nothing but the best parts such as forged and billet cranks, forged and billet connecting rods, forged pistons, ductile iron and steel rings, ARP rod bolts and head bolts, stainless steel valves, top quality valve springs, forged aluminum or steel performance rockers, thickwall or oversized pushrods, roller lifters and double roller or belt cam drives. There’s no cutting corners if you want a marine engine to last.

Anything that is exposed to water (especially salt water) has to be corrosion resistant. That means anodized coatings for aluminum heads and intake manifolds, stainless steel or bronze plumbing and fittings, brass or stainless freeze plugs, and some type of marine paint or anti-corrosive coating for the block, oil pan, valve covers and timing cover.

Because marine engines are running hard most of the time, they require a lot of cooling. Boats that use external water cooling suck water into the cooling system through an inlet port under the boat or in the stern drive. A separate water pump pulls water in and routes it to a second water pump on the motor (mechanical or electric). The water pumps have to have corrosion-resistant impellers, covers and housings.

Water-cooled exhaust manifolds are used with many inboard engines. A heat exchanger may be used to raise the temperature of the incoming water. The water-cooled manifolds also help prevent heat buildup in boats where the engines are in a covered compartment.

The constant load on a marine engine means it runs hot, even with lots of cooling. More heat causes greater thermal expansion so you have to allow a little more piston-to-cylinder clearance to reduce the risk of scuffing. Ditto for the valve guides. Exhaust valve seats should also be wider for better heat transfer, and seats should be a copper alloy to promote rapid heat transfer.

Special coatings can also help prevent heat damage on critical parts. A friction-reducing anti-scuff coating on the piston skirts and bearings can provide added insurance, while heat reflective and dissipating coatings can help manage heat elsewhere in the engine.

Most of the high performance marine engines that are being built today are running fuel injection rather than a carburetor. Fuel injection is easier to tune, and maintains a predetermined air/fuel ratio more accurately than a carburetor. Boats bounce around quite a bit, which causes fuel to slosh inside a carburetor. Marine carburetors are designed to keep the fuel in the bowls, but even so they can’t match the accuracy of a good fuel injection system. Starting is also easier with fuel injection, and you won’t have to wait for the engine to warm up so it doesn’t bog or stall.

Marine distributors must have spark arrestors (same for alternators and starter motors) and be cost guard approved so they don’t accidentally ignite any fuel fumes that may have accumulated in the engine compartment. Most of the engines that are fuel injected don’t use distributors and instead use some type of coil-on-plug ignition.

Keeping a marine engine lubed is also a challenge because of all the up-and-down vibrations that waves produce. Oil pans have to be stronger, and have plenty of capacity so the motor doesn’t run out of oil, and have baffles and a windage tray to keep the oil where it belongs. An external oil cooler is also essential to manage the heat, and an oil temperature thermostat is usually part of the system so cold oil can bypass the cooler and come up quickly to normal operating temperature. The oil pump and pickup tube should also be braced and the tube brazed to the pump to withstand all the vibration and pounding it will experience in a boat.

On really high output engines (1,000 horsepower or more), a dry sump oil system is usually the best way to go to assure a constant supply of oil to the motor.

The service life for a marine engine may range from 500 to 600 hours, while that of a 1,000 hp-plus engine might only be 200 to 300 hours. Some marine engine builders recommend freshening up the valve springs and hydraulic roller lifters after 200 hours of use.

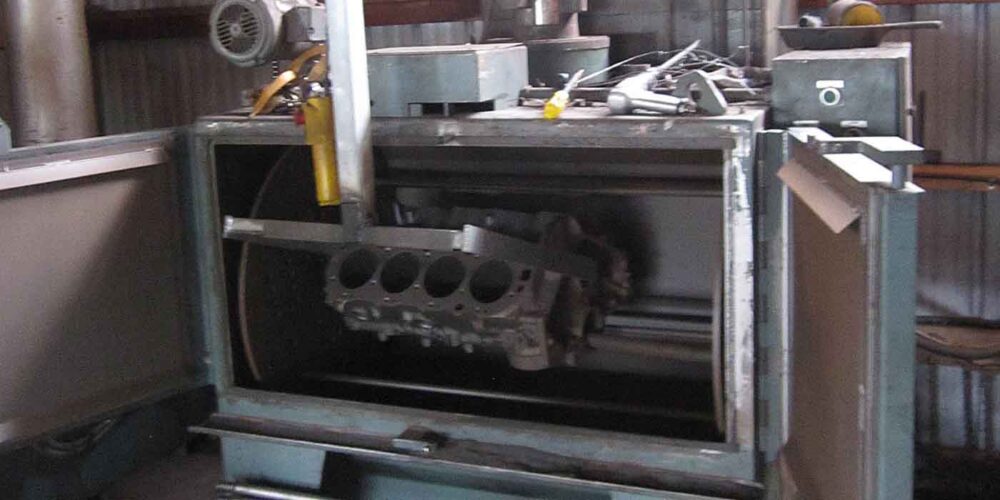

Engine assembly is pretty much the same for a marine engine as with a high performance automotive engine, with careful attention paid to clearances, cleanliness and fastener torque. But the exact clearances that work in a marine environment will be different than those for a land-based application. That’s where experience comes in. The guys who have been building marine engines for a long time know what works and what doesn’t. Reliability is absolutely critical with a marine engine because you don’t want a customer stranded a long ways from land. You can’t just get out and walk to the nearest marina for help or call AAA. And if a customer just spent a ton of money on a motor that didn’t hold up, he’s not going to be a happy customer or a repeat customer.

To find out more about this market, we interviewed several people who are building marine engines to get their perspective on the subject.

Teague Custom Marine

Bob Teague of Teague Custom Marine (Valencia, CA) specializes in high output motors for pleasure boats. “We’ve done a lot of offshore racing motors, but now mostly concentrate on pleasure craft,” he says. “We currently have 50 engines in the shop and another 50 boats waiting for work. We get business from all over the world.”

Teague says one of his specialties is building CARB-compliant 825 and 1,400 horsepower engines for the California boating market. These are blown motors based on Merlin big blocks, and have special cylinder heads designed by Teague and manufactured by Airflow Research. “Everything that goes into these engines is the best quality because marine engines are always running uphill,” he says. “They are constantly under load. We are using cams with the LS1 firing order, not so much for smoother operation or higher power but to improve emissions. The engines with hydraulic roller cams run at 6,400 RPM at full throttle while the higher output motors use solid rollers rev to 7,400 RPM. We make all of our own billet adapters, accessories and fittings, and sell to other marine suppliers and engine builders.”

Teague says he prefers that his customers drop off their boats with the engine in place. This way he can do the installation after the engine has been rebuilt or replaced. “Doing the installation allows us to make sure the job is done right.”

Crockett Marine

Tyler Crockett of Crockett Marine (Ruby, MI) is another marine engine builder who focuses on pleasure craft. He says he currently has 42 engines that have to be built this winter so he is not taking on any additional work until spring.

“We are mostly building big block Chevy motors, fuel injected and naturally aspirated, although a few are blown,” he says.

Crockett builds his motors to run relatively cool, around 95 to 100 degrees F, to minimize the risk of overheating. He also uses coated pistons and bearings for added protection. “We’ve torn down engines with coated bearings and they still look good as new.”

Tuning is critical for peak performance as well as practicality. Motors are tuned to provide peak power within their cruise and peak RPM range, but also at idle so the motor doesn’t stall when the boat is coming or going from the dock.

“We use a special 10 to 12 quart oil pan with baffles and a windage tray to control the oil in the crankcase,” he says. “On engines over 1,000 hp, we go with a dry sump oiling system. We prefer WIX oil filters because they flow better than many other filters. This is important because the motor relies on oil cooling as well as water cooling. An oil thermostat allows the oil to bypass the oil cooler until it reaches 180 degrees. Then the bypass closes to maintain a consistent oil temperature.

“As for cams, we use an LS firing order because we’ve found it reduces the pounding on the #2 and #4 main bearings.

“On salt water applications, we coat the inside of the water jackets with a Promax marine coating. Gaskets are all stainless steel, and the outside of the motor is sprayed with a Mercury marine rust protection paint.”

Crockett differs from Teague in that he prefers customers send him the engine rather than the entire boat. “It saves us the time because we don’t have to remove and install the motor, and we don’t have to store the boat until the job is done.”

Sonny’s Racing Engines

Sonny Leonard of Sonny’s Racing Engines (Lynchburg, VA) says the bulk of his business is building big cubic inch engines for drag racing, street performance and truck pulling, but that

only about 10 percent of his business is building marine engines.

“We do a 820 cubic inch naturally aspirated engine that can make 1,450 horsepower on 92 octane unleaded marine gas,” Leonard says. “It’s a billet block that we designed, along with our own heads and intake manifold. On race gas, it can make up to 1,600 hp.”

Leonard says he likes big cubic inch motors because they can make more power with less stress than a smaller engine with a blower.

“For marine use, we use Inconel exhaust valves, a less aggressive cam, valve spring oilers, and a tool steel cam,” he says. “We use Jesel 1.62 rockers and Diamond/Wiesco pistons. The water jackets are coated to protect against corrosion, and all of the external fasteners are either stainless steel or chrome plated.”

Marine Kinetics

Bob Madara of Marine Kinetics (Rochester, NY) says about 70 to 80 percent of his business is marine, with the rest being automotive high performance. “Most of our marine customers own a pleasure boat of some type or do offshore racing. As a rule, most boats under 25 feet in length have a single engine, while most over 25 feet have twin engines.”

Madara said most of his customers who own boats with two engines use an outdrive that eliminates the need for counter-rotating engines, so both engines can rotate in the normal direction.

“The typical high performance marine customer may spend $30,000 to $50,000 on a motor, times two if they have two engines,” he says. “We do a mix of naturally aspirated and blown engines. But some guys may only want to spend a few thousand dollars to refresh an engine or add a little extra power, so we do those kind of jobs, too.

“Engines that use fresh water or salt water cooling obviously need corrosion protection. The cold water also tends to shock the front cylinders. But closed cooling is another option that allows better temperature control, less thermal stress on the engine, and the use of antifreeze for corrosion protection.”

Although marine engines are similar to automotive engines and use many of the same parts, Madar points out some critical differences. Clearances are different, aluminum heads need to be anodized to protect them from corrosion, and everything that goes into the engine has to be top quality for durability. This is especially important with the valve springs.

Madara said the life of the valve springs depends on the quality of the wire, the engine’s power output and how many hours it runs at cruise to wide open throttle. “A set of valve springs in a 502 CID motor should probably be replaced after 300 to 400 hours even if they still look and test okay. That’s because valve springs can suddenly fail with no warning. Better safe than sorry!”

Madara says he uses 2618 forged pistons because of the additional ductility they provide. He said other alloys are harder but feels they don’t hold up as well in a marine application. He also likes coated skirts for added scuff resistance, and offers coated or uncoated bearings depending on what a customer wants.

As for the fuel system, Madara said most customers today want fuel injection rather than a carburetor. There are a lot of advantages with fuel injection such as easier starting and tuning.

For lubrication, Madara says he uses a special marine oil. “It is actually a 15W-50 oil with good cold flow characteristics, which is better for our local climate which is cooler than Florida or the West Coast.”

While marine engine building is a niche market that can be lucrative and rewarding, you have to have the know-how and experience to be competitive in the market.