RKLAB AG is a technology company in the process of commercializing a new diesel fuel injection system, the RK Injector (RKI). The technology is a self-pressurizing fuel injection system that is a direct replacement for the current common rail diesel fuel injection system. Benefits of the technology include a significant reduction in cost and weight to a vehicle, a 15% or greater fuel efficiency improvement and a dramatic reduction in both NOx and particulate emissions.

Key Markets:

- Heavy Truck market – both new and existing engines

- Generator Set market

- Diesel cars and light trucks

- Construction and Agricultural Machinery

- Rail and Marine engines

The RK Injector has been designed to be utilized in the retrofit after sales market thereby significantly increasing its speed to market and the scale and scope of the opportunity.

RKLAB has recently signed a Joint Development Agreement with Mazda Motor Company for the further development and optimisation of its RK Injector technology for use in diesel engines.

The Joint Development Agreement is a comprehensive program, which will be rolled out over the next two years to evaluate, test and improve the injector for use in the next generation of diesel engines. Mazda will work with RKLAB’s technical team and technical consultants Power Train Limited (PTL) to develop a range of prototype injectors for testing, evaluation and development at the Mazda powertrain laboratories and facilities in Hiroshima, Japan.

In parallel with the Mazda program, RKLAB has designed a program of on road trials and independent laboratory engine fired tests, for engine EPA certification in both Europe and the USA.

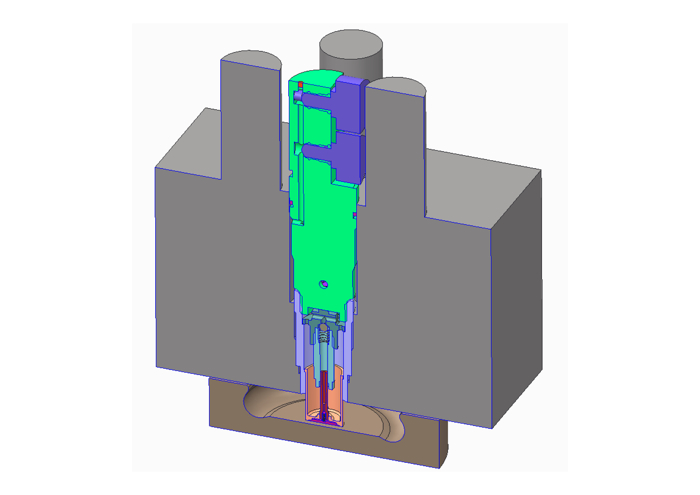

The RKI is a self-pressurizing fuel injection system. The RKI multiplies the initial combustion chamber pressure within the injector and forces the diesel fuel into the combustion chamber at ultra high pressures through up to 180 tiny holes, 1 thou diameter. The system eliminates the need for additional pressure pumps and expensive after treatment systems.

The RKI system is based on a novel fuel injector design that differs in its operation from conventional injectors in important ways offering:

- New opportunities for controlling emissions from compression ignition engines, and

- Subsequent opportunities for improving engine performance and reducing manufacturing costs compared with engines running on conventional fuel injection systems.

![Picture2_large[1]](/wp-content/uploads/Picture2_large1.jpg)