Can You Benefit From Having Both?

If you’re in the market for a dyno, you’ll have to answer a number of questions – namely, whether to have a chassis dyno or an engine dyno. Of course, as a responsible shop owner, you’ll need to consider how much room you have available in the shop, as well as the total investment it will take. But when you put those two things aside, you need to ask yourself how you’re going to utilize the dyno and which one best suits your business. And, if you have the cash, could you benefit from having both a chassis and an engine dyno?

To help answer these questions, we spoke with a couple shops that utilize both dyno types to get their take on the advantages, disadvantages and reasons to have one over the other or both.

In Georgetown, TX, Texas Speed & Performance has both a Dynojet 224 in-ground chassis dyno and a Superflow 902 engine dyno. The shop is even planning to add a second engine dyno to the facility for more constant testing.

“We started with the Dynojet in 2002 as we were more of an install facility when we first opened,” says Joseph Potak, a tech at Texas Speed. “As we developed more and more products, our focus shifted more into manufacturing and less and less customers’ cars. We initially rented a local engine dyno to test cylinder heads and camshafts. After seeing the benefits of the engine dyno for our usage, we then bought our own in 2009 for in-house testing and development.”

Further West in Gardena, CA, Custom Performance Racing Engines (CPR) also started off operations with a chassis dyno. The shop has a Dynojet inertia dyno, which is a single roller, two-wheel drive, and has access to a Dynocom four-wheel-drive eddy current dyno nearby.

“Before we were in the engine business, we were tuning cars on the chassis dyno,” says CPR Engines owner Martin Marinov. “As we entered the engine business, we acquired an engine dyno.”

Chassis Dynos

For a car builder or a shop that installs engines, the chassis dyno is usually the last place in the shop the car is tested. Things like overheating or leaks will show up here before a vehicle leaves the shop.

“The chassis dyno is a useful tool to diagnose drivetrain problems and is good for tuning,” Marinov says. “You can verify that the vehicle is safe to drive on the road because you can check for leaks or other issues you might have in the drivetrain. Those things will show their ugly head when it’s under load on the chassis dyno. We’ve had tires fail, driveshafts break, u-joints break, transmissions fail, and we’ve found electrical problems with vehicles.”

Again, CPR Engines has access to both an eddy current dyno and an inertia dyno, which the shop uses for different applications.

“With the eddy current dyno, you can put a load on it at any rpm to simulate different driving conditions,” Marinov says. “With an inertia dyno, you only have the weight of the rollers slowing down the engine, so you can’t do too much EFI mapping on an inertia dyno. You have to kind of guess where the load is going to be and what those cells are going to want when you’re doing ECU mapping for fuel injection tuning.

“With a load control dyno, you can vary the rpm acceleration of the vehicle in relationship to the throttle percentage. We can go 50% throttle and keep the engine at 2,500-3,500 rpm, until you exhaust the rpm of the throttle percentage. Then, you can vary the throttle angle at a certain rpm. For example, you could hold it at 4,000 rpm steady and then move the throttle throughout the range and hit every load cell along the way.”

While CPR Engines utilizes the chassis dyno often, Texas Speed & Performance uses its chassis dyno minimally, as the shop’s focus has shifted away from engine installs.

“When we do use it, it is used for vehicle specific components that we cannot easily test on the engine dyno such as exhaust systems, induction kits and aftermarket items like intake manifolds or throttle bodies to test those on a specific vehicle application,” Potak says. “If we did installs for customers, the chassis dyno would have a lot more usage as you would want a baseline to determine engine health before adding parts, and then you would do a dyno tune to calibrate the ECM for the new parts.”

Engine Dynos

While a chassis dyno is best suited for full vehicle testing and tuning, an engine dyno is best used for engine development and performance enhancements.

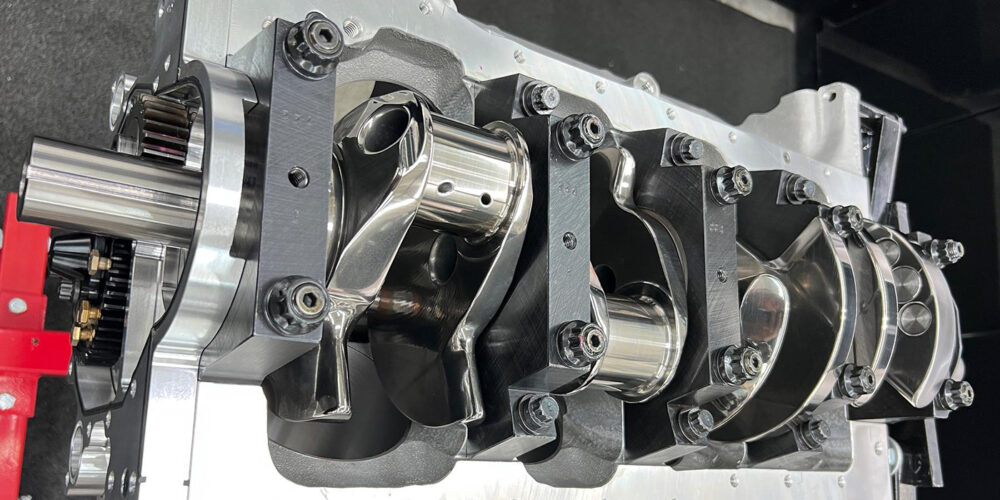

“We offer an engine break-in and testing service for customers who want their engine tested and proven before we ship it to them,” Potak says. “Typically, we spend a couple hours for the process of warm up cycles under load, calibrating the ECM file, changing oil, then if desired, we will do sweep tests typically from 3,000 rpm to 7,000 rpm – depending on engine setup. Usually three pulls is enough to have a reliable dyno graph and ECM tune.”

While a majority of shops will use a dyno for testing customer engines, Texas Speed puts an emphasis on developing new engine parts using the data from the dyno.

“We machine and build our own engines, cylinder heads, intakes and camshafts in-house, and we always put new parts through a test process way before the customer has the opportunity to purchase the parts,” he says. “With constant development, there is always a need for testing. There may be three months of solid dyno work when we do camshafts for a new engine, and one change at a time is performed – like trying a new exhaust lobe design.”

According to Marinov, engine dynos are great for testing engines if you’re shipping engines out of state or worldwide. This minimizes the chances of failures or mistakes happening when customers start-up the engines.

“You’ll want to test the engine before you ship it out for simple things like rear main seal leaks, water leaks, valve cover leaks, and pinholes in the oil pan,” Marinov says. “Manufacturers do their best to find the leaks, but sometimes one or two will make it through. You can also verify that all the components you’ve chosen for the customer live up to their performance needs and expectations.”

A session on the engine dyno is a good starting point for any engine. A proper break-in is the number one reason to put an engine on the engine dyno.

“You to make sure you get that initial ring seat and seal and give it a good baseline tune up, whether it’s an injection system, carburetor, alcohol injection or mechanical injection,” he says. “Obviously, once it goes in the vehicle, it’s going to see different load conditions, so the tune is going to have to be finessed. But at least the customer has a great starting point.”

Another way the engine dyno is very useful is to map out a fuel curve and a timing curve. Different cylinder heads might have different efficiency and combustion chambers and will require more or less timing. The same goes for piston dome profiles or dish profiles. Those things can make a big difference.

“If you’re used to running 35 degrees and you now have a more efficient cylinder head that likes 28 degrees, you might be giving it too much timing, which will result in premature engine failure, breaking parts or melting stuff,” Marinov says. “What we like to do is start off with a conservative number and work our way towards making more power. Then, we’ll maximize the power and back it off.”

If you put the work into a dyno session, it can pay off immensely. For instance, Texas Speed recently had an LS engine churn out 715 hp on the dyno, which was a solid starting point. But the shop and the customer wanted more.

“With optimization and spending a lot of time finding every last bit of horsepower on the dyno, we finished with 752 hp,” Potak says. “The first 715 hp was easy. The last 37 hp was the real work, and if you are not dedicated enough you would still have the 715 hp results.”

Advantages of Both Dynos

While any engine shop can benefit from having a chassis or engine dyno, most shops can get away with the use of one or the other. However, there are shops doing the full spectrum of work – engine and vehicle builds – that would necessitate the use of both dynos.

“There are many times where I will run the engine on the engine dyno to check for leaks, get a base tune and make sure everything is happy,” Marinov says. “Then, we’ll put it on the chassis dyno and see what it makes, verify the tune, and it gives us an idea of what we’re losing through the drivetrain. We’ll have a flywheel number and we’ll have a baseline rear wheel number.

“If you’re doing some form of racing and you think maybe something’s happening with the engine, it’s good to have that data because it’s a lot easier to just put the car on the roller, strap it down and see if it’s making the same power it was when you sent it out with the same settings. If it’s not, then you can start digging into it a little bit deeper.”

If you’re toying with the notion of using both kinds of dynos, it may be in your best interest to rent one hourly from a neighborhood dyno shop to test the waters.

A Critical Tool

Dynos, and the sessions you have on them, are valuable tools, just like having the right diagnostic equipment. The data you gather is irreplaceable.

“Everything works together, and once we know the power curve of an engine, we use that data to determine the torque converter, shift points and even the gear ratio we want to put in that car,” Potak says. “The average power is what really wins and matching the car to that completes the package. Peak hp/torque is just the max it does at a certain rpm, but anyone who understands racing knows the peaks are just one glimpse of the full story.”

If your shop is building race engines, doing engine or component development and/or durability testing, the engine dyno is the easy choice.

“You can test individual components to build a better combination,” Potak says. “This is where you can change the valve lash of a solid cam and see what works best or try different race fuels to see what the engine is happiest with. You can easily adjust the ignition timing curve and see results immediately.”

Conversely, if your shop is focused on installing and tuning parts such as superchargers, heads/cam packages, turbo kits, exhaust systems and even crate engines, then the chassis dyno may be the better choice. It really comes down to your shop’s needs.

“It’s not crucial to have both,” Marinov says. “Obviously, with the price of dynos and the availability of chassis dynos out there, I would go with an engine dyno. If you’re an engine builder or machine shop and you need to pick one or the other, I would go with the engine dyno because it’s more fitting.

“If you do both installations and engine building, then you could probably get away with just having a chassis dyno. You’ll open the door to more business and then eventually get an engine dyno or at least a run stand.”

No matter which way you go with your dyno decision, there’s no denying they are a very useful tool for building the best performing engines possible.

“Getting the horsepower and torque figures is what most people are fixated on,” Marinov says. “That’s great, but the big picture is to make sure the customer gets a good running vehicle and good running engine that’ll last for the duration of the racing season or whatever their expectations are. The devils in the details, as they say, and it’s often the little things that get you in trouble. The dyno is what protects you.”