Diesel of the Week is presented by

Drew Pumphrey’s first diesel truck – a 1988 Ford – had a 7.3L indirect injected naturally aspirated engine, and was a gateway drug, so-to-speak, that fueled Drew’s obsession with diesel performance. Drew owned that truck in high school and saved his money to purchase a Banks turbo kit for it. Having tasted what more power felt like, there was truly no looking back after that!

Of course, performance work on a diesel engine is never finished, so when Drew’s friend bought a ’95 Dodge with a Cummins and was able to make more power so easily, Drew refused to be outdone.

“I sold my Ford and bought a 1997 3500 Dodge with a Cummins at 18 years old,” Pumphrey says. “My passion for diesel performance made me work very hard on a local farm to buy parts for my truck. I started truck pulling before graduating high school. I went to school and worked a 40-hour week to buy the next part to give my truck more power. I was hooked.”

Drew attended the University of Northwestern Ohio and received his Associates degree in Auto/Diesel, while still working 40 to 60-hour weeks to fund his truck pulling addiction.

“I was so addicted that there were times I had to win money at a pull just to be able to buy fuel to get home,” he says. “I did everything possible to make more power or get to the next level. I remember missing Thanksgiving Day at home because I broke the transmission in my truck. I was cleaning parts in my kitchen sink and rebuilt it in my apartment.”

With a passion as strong as Drew’s, it’s no surprise he wasted little time getting further invested in diesel performance. After college, he went to work for Enterprise Engine in 2004, where he did general service work and performance engine builds on Dodge Cummins engines. That job made his pulling habit easier, and the wins started trickling in.

“Within a couple years, my truck got out of hand and was a full-time puller with open drive line,” Pumphrey says. “I had won a points championship in 2006 in a Run What Ya Brung class at USA East. I was the first-ever diesel to win that class, which was a mix of gas and diesel trucks. We won all but four hooks, received two second places and broke front axles twice, getting fourth in those hooks. I would work day and night to push forward.”

By the time Drew left Enterprise Engine, he was managing the day-to-day aspect of the whole business and had developed an interest in CNC machining.

“I purchased a small CNC Bridgeport mill in 2009 and started D&J Precision Machine as a side job,” he says. “I was consumed with learning how to make parts with it. However, I had no idea what I was doing. I was looking at code with no idea what I was looking at or what to do. I remember thinking I was so screwed.

“My father had purchased Wendy’s stores in Utah and wanted me to take over for him, so I left Enterprise Engine and worked for Directional Boring Company until I was ready to move. Soon after leaving Enterprise I had people asking me to build engines. One of them was Rocky Roark, the owner of the Directional Boring Company. I started working out of his shop nights and weekends while working 60-plus hour weeks for him boring. He loaned me $10,000 for the first engine I did at D&J and I built the whole business from that.”

Drew worked out of the corner of Rocky’s shop for about a year before he was too busy with side work that he had to quit boring. In June 2013, D&J Precision Machine officially got its own shop space in Zanesville, OH – 2,400 sq.-ft. – which was too small from the day the shop started!

“I hired my first employees and moved into a 5,000 sq.-ft. facility in June 2014,” he says. “I rented another 5,000 sq.-ft. across the drive in June 2015, and moved out of both of those buildings to 27,000 sq.-ft., where we are currently located, in June 2016.”

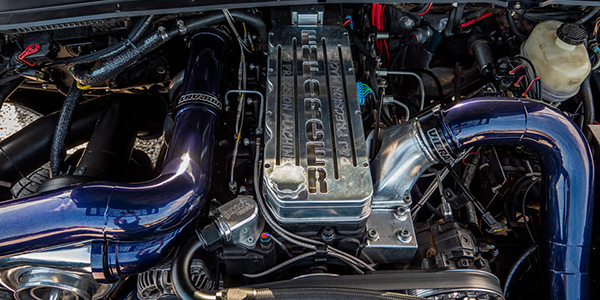

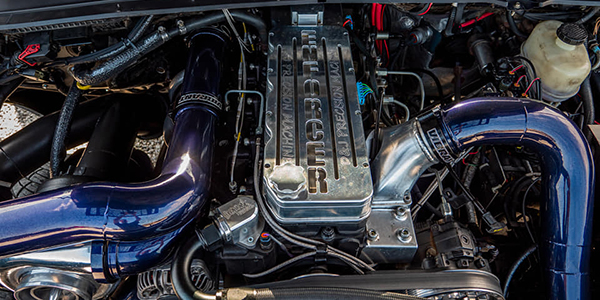

Today, D&J Precision Machine has 12 full-time employees and focuses on Dodge Cummins engines. However, the shop also makes parts for Ford Powerstrokes and does some private label work as well. Due to Pumphrey’s love for CNC machining, D&J is a full machine shop, capable of doing all work in-house.

“We currently manufacture our own connecting rods, girdles, billet main caps, deck plates, sleeves, and pistons, and we do our own cylinder head work, including 5-axis CNC porting, block work, including honing and boring,” he says. “We make our own billet intake manifolds and billet timing gear housings, titanium valve spring retainers, bronze lifter bushings, billet valve covers, and billet oil pans.”

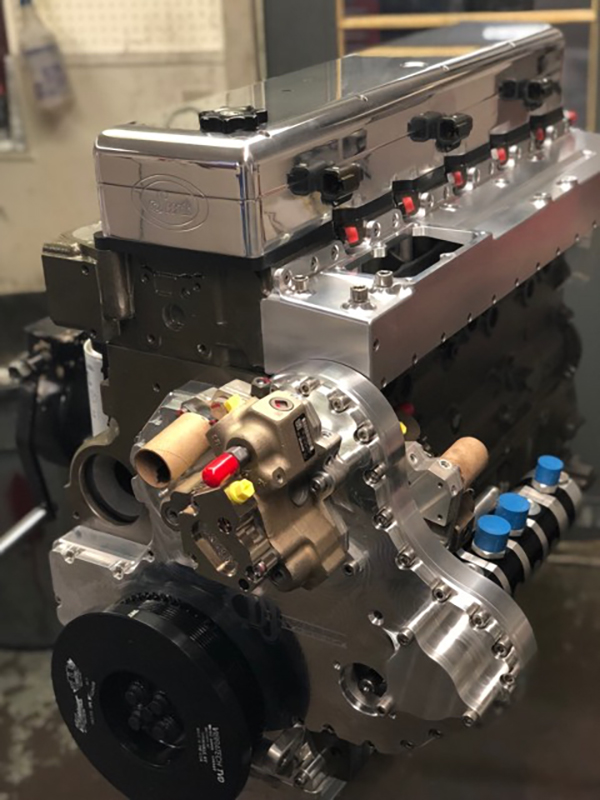

With all of those capabilities in one shop, it’s no surprise that D&J does a lot of machine work for other shops, and builds some great, fully custom diesel engines, such as its Enforcer engine – a 6.7L Cummins-based build.

“The first Enforcer engine was built for Firepunk Diesel in 2015 for the Diesel Power Challenge,” Pumphrey says. “Lavon [Miller] had broken a factory block in 2014, but did not want to lose the cubic inch of the 6.7L engine. I got together with my team and we designed the Enforcer engine. We wanted to retain the large bore of the 6.7L engine while increasing strength and still being able to run coolant in the block and make it as serviceable and repairable as possible. We have since sold over 50 of these long blocks in multiple configurations from 1,200 hp street engines to 3,000 hp sled pullers. We have seen over 4,000 ft.-lbs. of torque.”

D&J starts an Enforcer build with an OEM 6.7L Cummins block, crank and cylinder head. The basic Enforcer gets 9/16th main studs machined into the block, a D&J girdle installed and line bored. Since the stock Cummins block only has a front cam bearing, D&J installs cam bearings in every journal.

“We also bore the block for larger sleeves and install a 1˝-thick deck plate that we manufacture in-house,” Pumphrey says. “We have a proprietary system where we run tie bolts through the deck plate into the main web, adding lateral strength to the block. Our sleeve is a slip fit sleeve with a top flange so it can be easily replaced without going to the machine shop if there is a piston failure.”

From there, D&J starts work on the cylinder head by cleaning, crack checking and shot blasting the head.

“We remove the stock cast iron intake manifold and machine the head to accept our stage 3 billet replacement style intake,” he says. “We install new guides and larger seats. The valves get upgraded to a Ferrea super alloy valve on the intake and exhaust side. We finish these valves in-house to our own custom spec. The stock valves in these heads are 1.3˝ diameter on the intake and exhaust, and we upgrade to 1.5˝ on the intake and 1.45˝ on the exhaust.

“We 5-axis CNC port the head to 315 CFM intake and 265 exhaust. Stock is 165 intake and 145 exhaust. We install our own custom 115-lb. springs and titanium retainers. We also replace the press-in soft plugs under the valve cover with a thread-in soft plug that will not blow out with additional coolant pressure. We use a billet flat tappet cam spec’d depending on application with billet lifters. We use custom 7/16th .168˝ wall pushrods, stock rockers and billet bridges made in-house.”

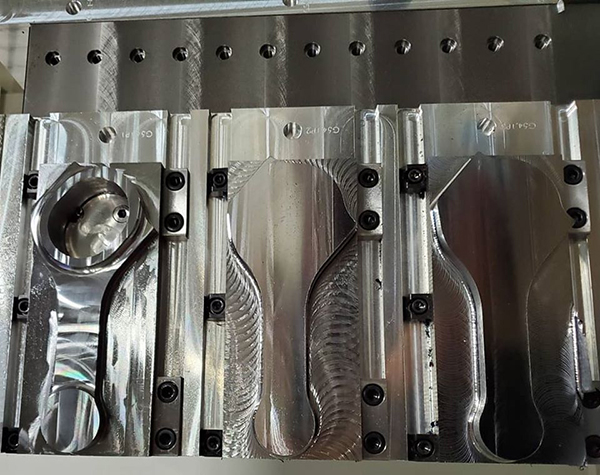

Moving to the rotating assembly, D&J utilizes its own X-beam, tool steel, 1˝-longer connecting rods, featuring a pressure lubed wrist pin and 1/2˝ rod bolts. D&J also manufactures its own pistons for this engine.

“Our pistons feature a steel ring land to increase durability of the top compression ring,” Pumphrey says. “We are the only piston manufacturer that has been successful at a 2618 forged aluminum piston with a steel ring land. We manufacture the steel ring send them out for forging with the aluminum and heat treat before machining the entire piston in-house. We use Total Seal rings, Clevite bearings and tool steel wrist pins. The stock crank gets balanced, crack checked, inspected and polished. We also offer a billet crank from Winberg, if the customer will be pushing the stock crank too hard.”

The head gasket is a modified stock gasket that D&J machines in-house and the compression is sealed with a fire ring. These engines normally run with a common rail fuel system, and D&J has additional upgrades available depending on application, such as a billet main cap to add more strength to the mains and roller lifter upgrades, which Pumphrey recommends on applications over 2,000 hp and 100 psi boost.

“We can also make billet timing gear housings that run multiple fuel pumps, dry sump oil pumps and mechanical P-pumps if the customer does not want a common rail fuel system,” he says. “We also offer an upgraded runner and plenum intake manifold. We ship this engine with a billet, LED Enforcer valve cover, billet front cover, billet soft plugs, and a 6.7L Fluidampr.”

In the years since D&J started building the Enforcer 6.7L, this engine platform has been a workhorse for its customers.

“Properly tuned, we have seen 100-plus passes over 2,500 hp before we have to refresh the engine with rings, sometimes pistons and bearings,” he says. “We currently hold the record for the fastest 4wd truck with a 4.97 at 151 mph and the fastest diesel door car with a 4.25 at 174 mph. We have a three-time Ultimate Callout Challenge winner, a Diesel Power Challenge winner, Outlaw Diesel Pro Street points champion, and an Outlaw Diesel Pro Mod diesel champion.”

With a pedigree like that, we have little doubt the Enforcer engine platform is in for even more success in the near future.

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].