Diesel of the Week is presented by

You might know Josh McCormack’s name if you pay close attention to the performance diesel world. He often competes in diesel events throughout the country in his 2005 Dodge truck. You might also follow his engaging social media and YouTube pages. And, you might recognize his name from our previous feature on him and his triple turbo 6.8L Cummins build in a 2020 Diesel of the Week, which ended up being voted Engine Builder’s Diesel of the Year in December.

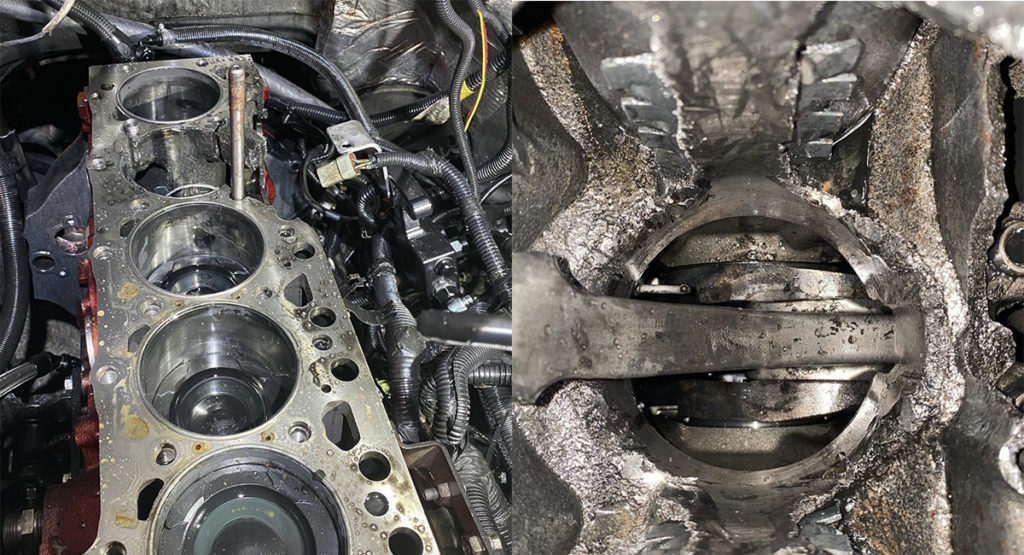

Josh is an employee at Power Driven Diesel in Cedar City, UT, and as Josh has continued to learn diesel engine building, he’s gotten more and more adamant about pushing the limits of diesel engine performance. As such, his Diesel-of-the-Year-winning 6.8L Cummins suffered an unfortunate death last summer trying to reach 2,000 horsepower during testing.

“I have dedicated my adult life to diesel motorsports,” McCormack says. “The 6.8L build was a culmination of 11 years in the industry. I have lost sleep and my stress levels have been maxed out. Most of the engine is a total loss – a chunk of the block hit the starter and shorted out the new datalogger, ECM and the dash. Part of me wants to throw a stock engine in it and send it on its way, or hunker down and build another one.”

In true diesel style, Josh opted to go for another build. Having to leave the 6.8L Cummins behind after it blew apart, Josh turned to D&J Precision Machine for a 6.7L Cummins-based Enforcer build to put his goals back on track in 2021.

“2,000 horsepower [was] the goal for the 6.8L Cummins, but the real conundrum we’re facing are the limits of the competition wet block,” McCormack told us last year. “We have enough wastegate, turbo, nitrous, and fuel to do 2,400 hp.”

This is where D&J’s Enforcer engine will help Josh immensely. Drew Pumphrey, owner of D&J, wanted to retain the large bore of the 6.7L engine while increasing strength and still being able to run coolant in the block and make it as serviceable and repairable as possible. These Enforcer long blocks come in multiple configurations from 1,200 hp street engines to 3,000 hp sled pullers.

D&J starts an Enforcer build with an OEM 6.7L Cummins block, crank and cylinder head. The basic Enforcer gets 9/16th main studs machined into the block, a D&J girdle installed and line bored. Since the stock Cummins block only has a front cam bearing, D&J installs cam bearings in every journal.

They also bore the block for larger sleeves and install a 1˝-thick deck plate manufactured in-house. D&J has a proprietary system to run tie bolts through the deck plate into the main web, adding lateral strength to the block. The sleeve is a slip-fit sleeve with a top flange so it can be easily replaced without going to the machine shop if there is a piston failure.

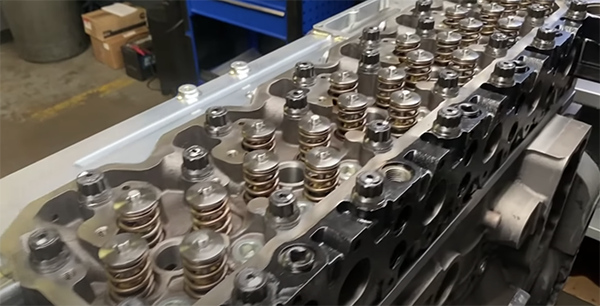

From there, D&J starts work on the cylinder head by cleaning, crack checking and shot blasting the head.

“We remove the stock cast iron intake manifold and machine the head to accept our stage 3 billet replacement-style intake,” Pumphrey says. “We install new guides and larger seats. The valves get upgraded to a Ferrea super alloy valve on the intake and exhaust side. We finish these valves in-house to our own custom spec. The stock valves in these heads are 1.3˝ diameter on the intake and exhaust, and we upgrade to 1.5˝ on the intake and 1.45˝ on the exhaust.

“We 5-axis CNC port the head to 315 cfm intake and 265 exhaust. Stock is 165 intake and 145 exhaust. We install our own custom 115-lb. springs and titanium retainers. We also replace the press-in soft plugs under the valve cover with a thread-in soft plug that will not blow out with additional coolant pressure.”

Moving to the rotating assembly, D&J utilizes its own X-beam, tool steel, 1˝-longer connecting rods, featuring a pressure lubed, tool steel wrist pin and 1/2˝ rod bolts.

“Our pistons feature a steel ring land to increase durability of the top compression ring,” Pumphrey says. “We are the only piston manufacturer that has been successful at a 2618 forged aluminum piston with a steel ring land. We manufacture the steel ring send them out for forging with the aluminum and heat treat before machining the entire piston in-house. We use Total Seal rings, Clevite bearings and tool steel wrist pins. The stock crank gets balanced, crack checked, inspected and polished. We also offer a billet crank from Winberg, if the customer will be pushing the stock crank too hard.”

The head gasket is a modified stock gasket that D&J machines in-house and the compression is sealed with a fire ring. These engines normally run with a common rail fuel system, and D&J has additional upgrades available depending on application, such as a billet main cap to add more strength to the mains and roller lifter upgrades, which Pumphrey recommends on applications over 2,000 hp and 100 psi boost.

“We can also make billet timing gear housings that run multiple fuel pumps, dry sump oil pumps and mechanical P-pumps if the customer does not want a common rail fuel system,” he says. “We also offer an upgraded runner and plenum intake manifold.”

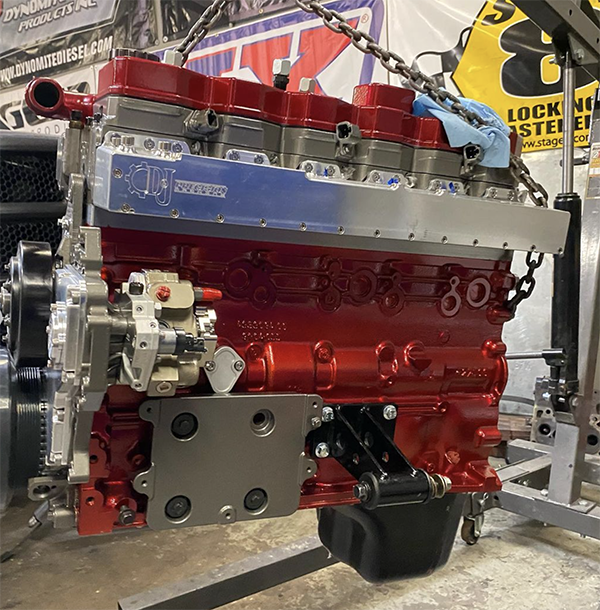

In Josh’s case, he’s looking to crack 2,000 horsepower and have a truck capable of drag racing, dyno competitions and truck pulling. His Enforcer features Dynomite Diesel injectors, an Exergy Performance 14mm stroker race series CP3, Armor Diesel semi-solid mounts, Manton roller rockers, a D&J 12-bolt flex plate, a Fleece Performance dual pump kit, a Fluidampr balancer, 9/16ths. Head studs and a Stage 3 head.

Josh also opted to upgrade to billet main caps, a 216/240 D&J steel roller camshaft, Keystone roller lifters, D&J’s 1-inch longer X-beam rods with tool steel wrist pins, a D&J girdle, a new front cover, and all new freeze plugs.

“I want to give a huge thank you to the team over at D&J Precision Machine,” McCormack says. “It was amazing to see that level of quality. After a year of getting kicked in the balls, I’m looking forward to this Enforcer engine. It was definitely worth the money, and after seeing the parts, seeing the attention to detail, I’m excited for where the truck can go this year.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].