When it comes to trying out new methods and theories to improve upon performance, often times, we’re learning using the old-fashioned way through trial and error. After any type of modification, the butt dyno is only good to a certain point. You could usually feel a difference any time you made a change in tuning, such as a different accelerator pump cam or distributor advance weights, but you really didn’t know for sure – without a dyno or track time – what type of difference you made.

Quick bolt-on “power adders” were usually the same way and sometimes you felt no difference, but one particular bolt-on that left no doubt about loss or gain was the intake manifold. This fact made it one of the more interesting components, especially to understand why it had such an impact. It didn’t take long to learn that wide open plenums and short runners would move the torque curve up the rpm range, and that long runners would move the torque curve down the rpm range.

It was easy to “visualize” the difference in air velocity and volume and understand the difference it made, but the importance of it in relation to engine efficiency is often understated, and the path of technology led to the internal airflow characteristics of an intake being where the majority of modern research efforts have been focused. When the intake valve opens, a low-pressure area develops in the intake runner. Air then flows through the runner into the cylinder in order to equalize the pressure.

When the intake valve closes, the velocity of the air creates high pressure that bounces back up the runner. The resulting resonance from this effect, as it turns out, is the driving factor in manifold performance. While there will always be the same fundamental shift in torque curve based on runner length and volume, managing the effects of this pressure inside a manifold are a constant area of research and LS intakes are no exception.

LS swaps are popular for many reasons, but there are a lot of variations and details to sort through – more of them than you may expect – and many of them are associated with the intake manifold. From the factory, there is a clear difference between the LS car and truck manifolds. The truck manifolds are taller (by over 3 inches) and don’t flow the same at high rpm, so car manifolds are more desirable for high-horsepower applications.

Most of the Gen III intake manifolds had cable-operated throttle bodies, and the Gen IV intakes had throttle-by-wire. Most of the manifolds will only work with the type of throttle body they originally came with, but there are some that will work with either type. There’s about a 50/50 split on the engines that came with cathedral port or rectangle port heads, but there’s more to it than matching the ports. Even if a manifold bolts on, in some cases the bolt patterns of the fuel rails, MAP sensor and throttle bodies were different, so you had to think ahead.

Of the more common Gen III cathedral port models, the LS6 manifold puts up better numbers than the LS1 to the tune of about 20 hp and 15 ft.-lbs. of torque. As a refresher, the LS1 was our first introduction to the Gen III small blocks in the ‘97-‘04 Corvette, the ‘98-‘02 Camaro/Firebird and the ‘04 Pontiac GTO, with an aluminum block and 305-350 hp, depending on application. The LS6 was the 385-405 hp monster that powered the ‘01-‘04 Corvette Z06 and ‘04-‘05 Cadillac CTS-V.

Surprisingly, the standard truck intake from this generation of LS engines performs quite well, nearly matching the numbers of the LS6 manifold, but most people think the truck intakes are just plain ugly. Where there’s a will there’s a way and many people have found ways of smoothing them out and making them look downright slick!

Most of the Gen IV engines featured rectangle port heads, and the LS3 intake is widely known as one of the best factory LS manifolds. The LS3 was the aluminum block 426-436 hp 6.2L version, produced from 2008-2017 for the Corvette, Pontiac G8, Camaro and Holden models. As with the cathedral port models, the rectangle port truck intakes come close to hitting the performance of the LS3, only with the same objection of looks, and like all the truck intakes, they are taller and may not fit under the hood of some cars.

The aftermarket industry has embraced the Gen III and Gen IV small blocks, as much as and maybe more than their predecessors, and while there are many possibilities with factory components, aftermarket intakes and accessories have really opened up the options and proven that there’s power to be found.

“Basically, for the LS platform, it’s a la carte,” says Bryan McTaggart of Holley. “It’s what do you want and how do you want it? We have everything from a High Ram EFI manifold to Low Ram intakes that have good flow but hide under the hood. We have cast manifolds, fabricated sheet metal manifolds and composite manifolds too.”

Among the options that can make an LS swap easier are throttle body adapters for various intakes to go from three to four bolts, as well as clocking adapters when battling accessory clearance issues. Fuel injector and fuel rail adapters and fittings add to the scope of adaptability as well as throttle cables, brackets and electronic throttle pigtail adapters.

But let’s get serious. What about the power and what’s the most popular? As with any engine build, there are too many variables to state that one intake outperforms another and it all comes down the individual builds, as well as ultimately what you’re building the car for. No matter how you stack it, you’re still going to sacrifice low-end for top-end gains and vice-versa, but there are many popular aftermarket intakes that would sit proudly atop any LS build.

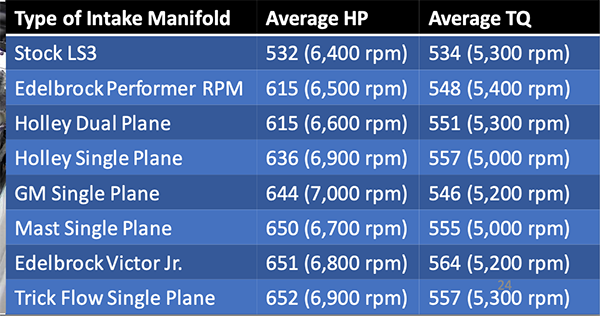

A comparison of the stock LS3 intake against a few of the popular aftermarket manifolds yielded the following results:

Are carburetors your game? Here are some test results comparing a stock LS3, then swapping out to old school.

To have some fun, Holley tested their Hi Ram intake setup on a 440 cid LS7 with different uppers for comparison. Specs for the engine were an eight-counterweight crank, 13:1 compression, LS7-style CNC’d heads, LSC dry sump setup, ATI damper, hydraulic roller camshaft, Holley 85 lb./hr. injectors, and Hooker 2” primary headers.

Starting with dual quad 4500 throttle bodies, this combination cranked out 754 hp and 624.9 ft.-lbs. of torque, but pointed out that this is primarily a drag racing or big-cube setup, with low-end sacrifices. Next were dual 4150 throttle bodies, which put up the numbers 747.7 hp and 621.3 ft.-lbs. The 4150 throttle bodies only provided half the cfm of the 4500s, but still had close numbers, and are much better suited for a street application.

Then came a much simpler and more affordable combination with the Hi Ram and a single 105mm throttle body upper, cranking out 732.6 hp and 606.5 ft.-lbs. Wrapping it up was the MSD Atomic Air Force single 105mm throttle body, which came in at 718.7 hp and 621.5 ft.-lbs. The numbers are lower, but this manifold had the lowest profile and would fit under most hoods, as well as provide the best low- to mid-rpm performance.

These various comparisons are the perfect example of the horsepower you can gain, as well as the sacrifices and the simple truths that we already know. The right manifold for any LS depends on the final application. EB