Diesel of the Week is presented by

Some of the best messages we get here at Engine Builder Magazine are from loyal readers who are appreciative of our content and get inspired by other people’s builds. Building an engine is a huge investment of time and money, and seeing people who aren’t as invested in the industry partake in a build is super cool to see.

We recently received a message from Eric Lucy of Abingdon, VA about a build he has been working on for some time.

“I hoped you and Engine Builder Mag might be interested in this 12v build my 16 (almost 17) year-old son and I have been working on together,” he said in an email. “He’s an aspiring mechanic, and I’m a full-time LEO supervisor for the town where we live. I cut my teeth building cars in the early ’90s and 2000s, doing everything from imports to classic muscle.

“I have a 2010 F-250 King Ranch crew cab as my side hustle truck and all around go-getter with a 6.4L Powerstroke diesel in it. I had it somewhat bulletproofed, deleted, EGR bypassed, etc. right away (I had a 6.0L Powerstroke before that…) but had not addressed the pistons. I was running a KEM custom tune on a Patriot tuner for towing about two years ago, towing a tractor back from Pennsylvania when one of the pistons finally blew through.”

Lucy knew that fixing the 6.4L would be expensive, and he’d always dreamed of throwing a Cummins in it, so that’s what he did. One of his friends who owns a local towing company had recently traded a used truck for a brand-new 12v 6BT Cummins long block that had been sealed in a trailer for years. He gave Lucy an offer he couldn’t refuse, and the build started right away.

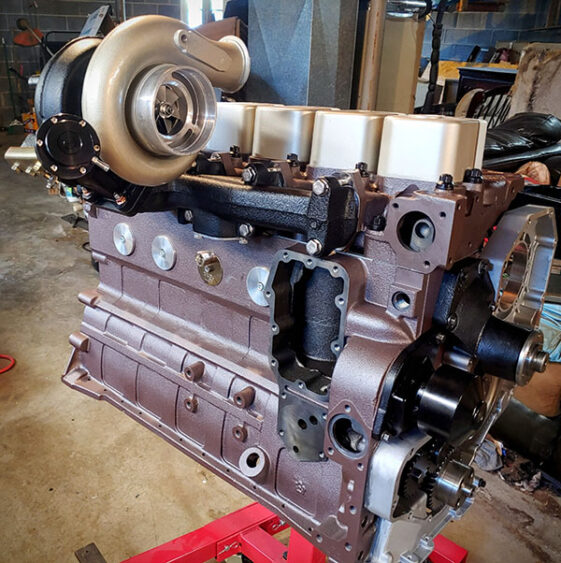

“I advised my son he was most certainly going to help, and it wouldn’t be a short-term project,” Lucy continued. “After bringing the engine home, I noted the indications of it having sat for some time. We made the decision to tear it completely down to the bare block. It was also equipped with the timing plate for a VE pump, so that had to go. I bought a second used 6BT for $1,000 and we removed all the brackets, fuel lines, the P7100 pump and accessory brackets. When we resold the remaining long block and we came out about even. We do some gun-related business on the side (I am an 07/02 FFL manufacturer) and cerakote/powder coat, paint and media blast in that capacity – so everything getting coated or painted was media blasted. The block and head were completely cerakoted in high temp semi-metallic matte dark brown.

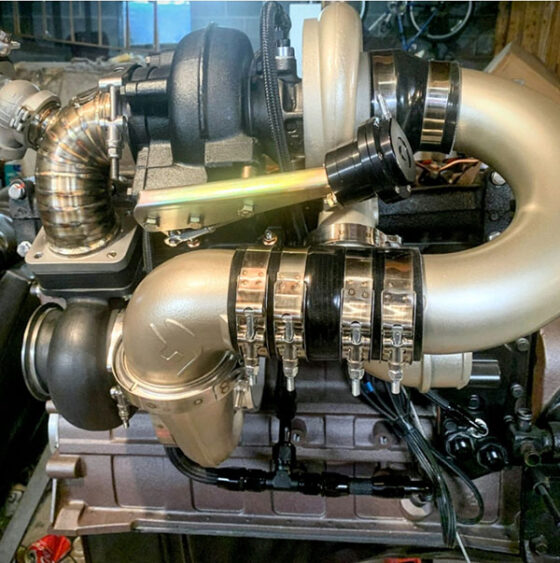

“The block and head were reinstalled with head studs from Xotic and valve springs from Street Sport Industries. Rocker pedestals were machined in-house on my Bridgeport series one Alliant clone, and the head was moderately worked with burrs and cartridge rolls to open up the throat behind the valve seats and shaped around the valve guide areas. The exhaust ports were all gasket matched to the modified stock exhaust manifold. This manifold had over a 1.5-lbs. of iron ground out of it to open up the interior and ports to match the head. A T4 adapter was bolted on and everything opened up to match that profile. Throughout the hot side, manifold, turbos, etc., everything got some profiling and gasket matching to hopefully help spool up time and reducing hot spots.”

Lucy and his son are using an HX40W primary turbo compounded with an S400. A friend did the pie cut hot side connection with a TiAL wastegate port, then they added a 1″ spacer attached to a support bracket that is bolted to the bottom of the flipped exhaust manifold. The manifold was also cerakoted, and the fuel lines were powder coated in a copper metallic finish.

Everything is plumbed with braided lines and AN fittings. It’s not on yet, but they’ll soon be running a Mishimoto intercooler and custom intake elbow with the ICT billet plenum cover. All the freeze plugs received the bolt in variety, with bypass coolant running to the rear of the block.

“My son located a 200gph Fuelab brushless pump and electronic fuel pressure regulator at an auction for a steal, so a custom setup using these two pieces will constitute our lift pump system,” Lucy told us. “The camshaft is a stock-ish Hamilton piece that we also traded for. The P-pump has had all the usual mods and is being flow tested, and we’re running 6×0.015 injectors for now and laser cut DVs. A 4500rpm gov spring assembly was also sourced from Street Sport Industries and we will be using the Adjuster by Attitude in the fuel plate.

“Boost will be controlled by a GFB duty cycle-type boost controller, with a 14-point gauge system from JRP that will monitor everything including wideband AFR in real time. We will be using a Turbosmart BFV controller to affect the TiAL blow off valve keeping turbo wear to a minimum.

“I have a water methanol system originally purchased for our BMW, but now it may make its way onto the truck to assist in high-boost situations. We aren’t going for maximum horsepower or torque, but expect pretty favorable numbers – I’m aiming more for efficiency and control.”

Lucy and his son have taken around two years to get to where they are currently, and finding time to work on the build has been difficult.

“Paycheck and weekend hours being at a premium. I teach at the academy almost constantly, and we work 12-hour shifts, rotating days and nights every month. I’m also a special Deputy US Marshal on the Fugitive Task Force and on the regional drug lab team. I am extremely blessed to have a family that supports this work, and to have an almost adult son taking an interest and doing his fair share is extremely appreciated.”

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].