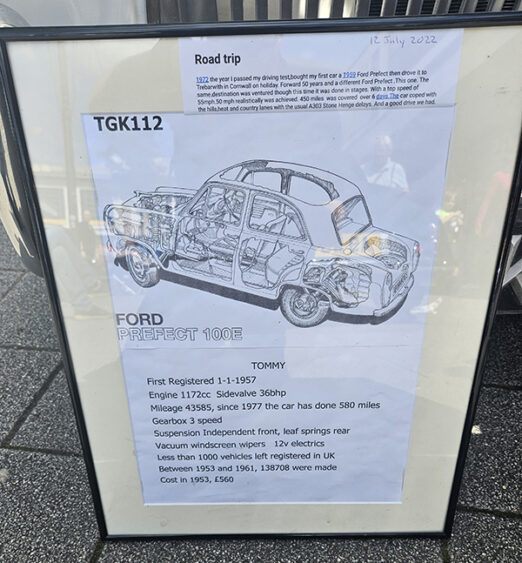

While attending a car show in Farnborough, England, I came across a 1957 Ford Prefect 100E. It was one of less than 1,000 registered in the UK. It featured vacuum-controlled wipers, super low miles (less than 44k), and was in beautiful condition. The engine was a tiny 1,172cc (1.2L) with a whopping 36bhp rating! The car is small, quirky, unique and features an engine I have never heard of before. The Ford Sidevalve.

It looked like an ordinary inline 4-cylinder flathead engine. Essentially it is, but it has quite a cult following here in the UK. They were cheap to build, ran smooth as silk, had great bottom-end torque, and were cheap to work on. But, they weren’t as fuel efficient as overhead valve engines, and they couldn’t make as much horsepower at higher engine speeds.

The Ford Sidevalve engine also referred to as the “English Sidevalve,” is a side valve (flathead engine) that originated from the British arm of the Ford Motor Company. This engine has a rich history dating back to the 1930s and was employed in various Ford vehicles, as well as other car models from different manufacturers. In this article, we will delve into the origins of the Ford Sidevalve engine, its modifications, power ratings, gearbox and transmission, applications, and more.

History and Origins

The Ford Sidevalve engine had its roots in the 1930s Ford Model Y and was produced in two sizes: 933 cc (56.9 cid) or “8 hp,” and 1,172 cc (71.5 cid) or “10 hp.” Sidevalve engines are also known as L-Heads or flatheads. This latter name was because the cylinder head is flat, it is a simple design because it has no valves in it, just a spark plug and fins for cooling purposes.

A Sidevalve engine has valves in the top of the block with each cylinder having a chamber at the top that houses the valves and gives it the name L-Head because the cylinder is shaped like an upside-down L. These engines used a simple pushrod system to open the valves from a cam that is mounted near the crankshaft. If you hear the phrase T-block it will describe a sidevalve engine with the input valve on one side and the exhaust valve on the other making the cylinder look like a T.

The early versions of this engine did not come with a water pump as standard. Instead, they relied on thermosiphon cooling (Thermosiphon is a method of passive heat exchange, based on natural convection, which circulates a fluid without the necessity of a mechanical pump) similar to the Ford Model T engine. It wasn’t until 1953, with the introduction of the 100E models, that a water pump was added when the engine underwent significant re-engineering.

During its lifespan, the Sidevalve engine was used in numerous smaller Fords, as well as farm vehicles, commercial vehicles, and even marine versions in boats. Production of the engine ceased in 1962, but its legacy continues to be appreciated by car enthusiasts and collectors alike.

Notably, the Sidevalve engine was also utilized in German Fords, starting with the Ford Koln in 1932 and ending with the last rear-wheel-drive Ford Taunus 12M in 1962. Only the 1,172cc version, originally designed for the English Ford “10 hp,” was used in German Ford lines.

Engine Modifications

Many methods were explored to enhance the power output of the standard Ford Sidevalve engine. Some of the most notable modifications included special exhaust manifolds, twin carburetors, stiffer valve springs, thinner cylinder head gaskets, and modified camshafts.

Power Rating

The nominal horsepower quoted for each engine size comes from the British method of power calculation for road taxation purposes. This bears no relationship with the actual power output. Factors such as engine displacement, cylinder diameter, stroke, and the number of cylinders determined the power for road taxation purposes. To minimize tax ratings, British designers developed engines with very long stroke and low piston surface area. The system discouraged manufacturers from switching to more fuel-efficient overhead valve engines as these generally required larger bores, while the established Sidevalve layout could easily use very narrow bores. Despite OHV engines having significant benefits in economy, refinement, and performance, the tax system made these engines more expensive to own because it placed them in a higher tax class than Sidevalve engines of identical power output.

Gearbox and Transmission

A three-speed gearbox was fitted as standard in vehicles equipped with the Ford Sidevalve engine, featuring three forward gears and one reverse gear. Several ways of improving performance through modifications to the gearbox and transmission were applied. These included the use of replacement close-ratio gears fitted to the gearbox, overdrive gears fitted behind the original gearbox, and higher-ratio crown and pinion gears fitted to the differential unit on the back axle.

The iconic Ford Sidevalve engine has left its mark on automotive history, and its legacy continues to be appreciated by car enthusiasts and collectors today.