The Racing Industry Gears Up for Indianapolis

Featuring roughly 1,200 exhibitors, the PRI Show highlights the latest advances in racing components, shop-machining equipment and engineering solutions, as well as special exhibits and seminars. There’s a lot to see, but it’s more than just the cool new parts, gadgets and equipment that make the trip to Indy worthwhile.

Oiling Systems for Grassroots Racing

Priority one when choosing an oiling system for any type of racing (grassroots or professional) is to establish what the rules allow and prohibit. Somebody has to read the rule book. Whether that’s you or your customer it doesn’t matter. The oiling system has to fit within the framework of the rule book. Period.

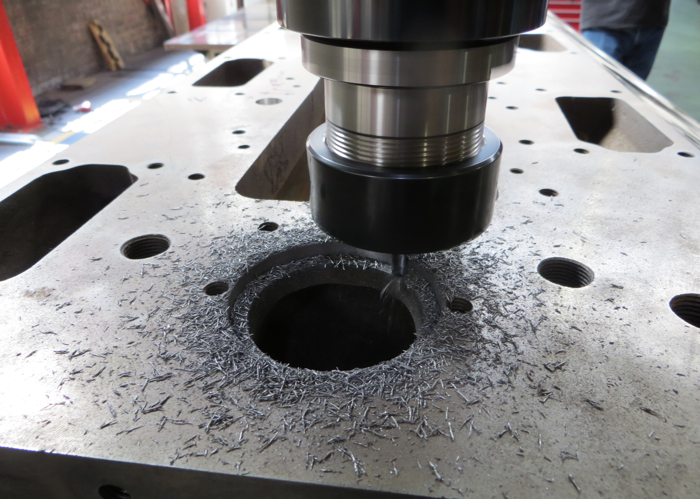

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

Super Class Act: Super Comp Engines and Drivers are a Different Breed

The three Super Classes are the only ones allowed a throttle stop. In the beginning of the Super Class fixed index racing history, racers had to set up the car and physically control their driving in order to run as close to the index as possible. When the throttle stop entered the picture, things changed drastically.

Shop Solutions November 2015

When assembling an engine, one of the most overlooked items is the timing chain sprocket alignment. The upper and lower gears should be installed and alignment checked with a straight edge. I have seen them as far as .020˝ off.

The Little Details Add to Your Bottom Line

A restoration shop owner we know sends his engines out to professional rebuilders. There are two engines sitting in his shop right now – a six and an eight. Both were rebuilt by different shops. One of those shops will be getting all of his engine work in the future. The reason isn’t the quality of work or even the price; it is the attention one shop paid to details.

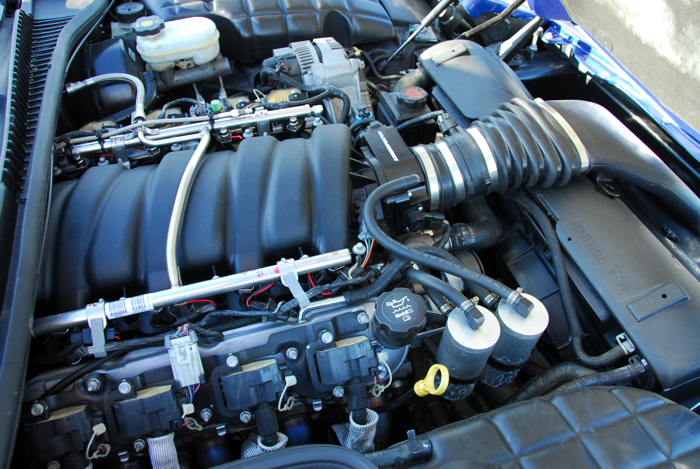

Building Trophy-Winning, Comp-Grade Engines

While the victor of multiple racing events usually gets all the attention, what about that unsung hero under the hood? A driver is nothing without a dependable engine that can go the distance. Here you’ll find how an engine builder can empower a talented driver, and some specific tips on tailoring an engine setup to a wide range of applications.

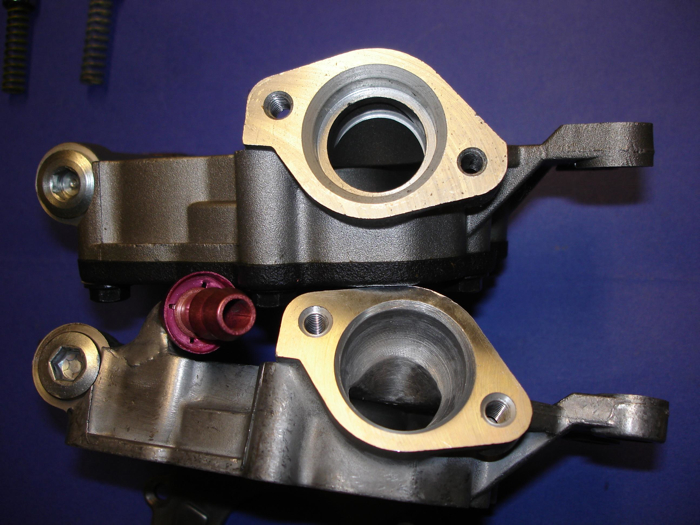

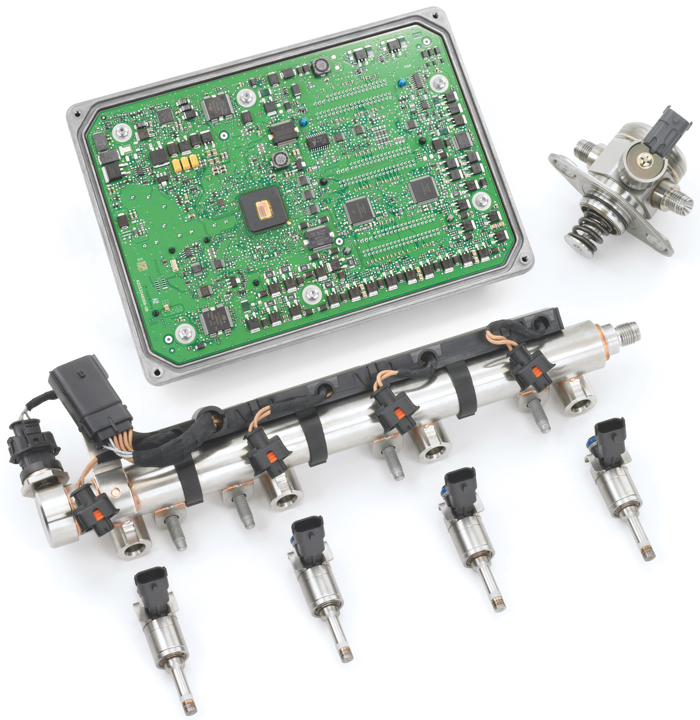

Direct Injection Gas and Diesel Technology

Direct injection is becoming standard on more and more late-model vehicles in both gasoline and diesel versions. These systems can be a diagnostic challenge, but with the right foundation, problems can be solved profitably. A better understanding of how they work can help you help your installer customers do a better job.

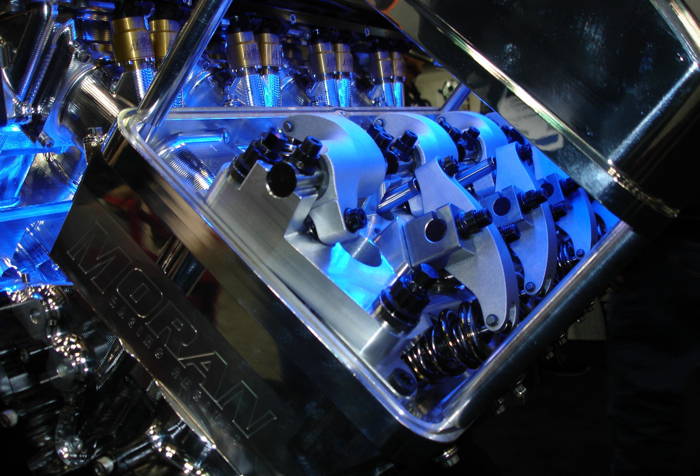

Keep the Valvetrain on Track

The key to choosing the right valvetrain components is to match the parts to the application. It sounds simple enough, yet many valvetrain component suppliers tell us there are a lot of misconceptions about what kind of parts are best for different kinds of performance applications.

Old Gold – Vintage Engine Analyzers and Distributor Testers

Engine analyzers and distributor testers are the most common types of equipment seen in the old-car hobby. Of the two, the distributor tester seems to be the more desirable and valuable type of machine.

Shop Solutions October 2015

Managing your scrap is an everyday chore. We all know aluminum pistons are worth more than aluminum mill waste, but by removing pins and rings they’re worth even more.

The Shameless Art of Self Promotion

As business owners many of us tend to follow the leader and do what everyone else does to promote our business. But…if that is what everyone else does how are you going to get any different results than everyone else in town? Sometimes you need to think outside of the box and do a little shameless self-promotion.