Future Alternative Fuels Could be a Gas

Alternative fuels such as E85 and biodiesel that were once considered fringe fuels are now mainstream. You can burn any mixture of gasoline and E85 in any vehicle that is Flex Fuel capable. As for biodiesel, blends ranging from B05 (5% biodiesel) to B100 (100% biodiesel) are being used in all kinds of diesel applications.

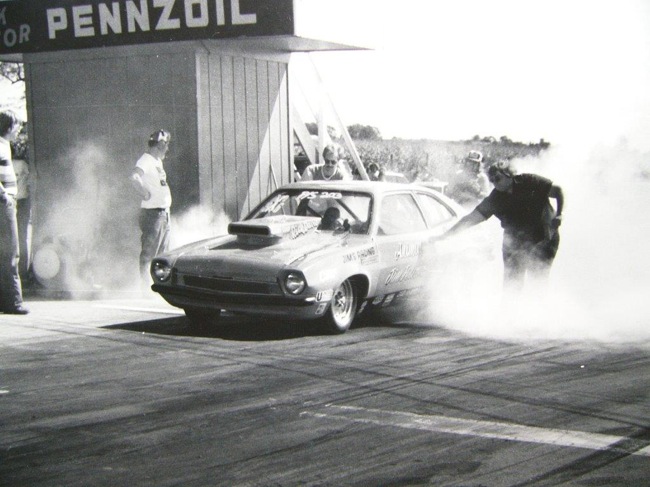

Learning To Race Pro Stock

My transition in 1975 from bracket racing a 122˝ wheelbase mid-eleven second, two-ton ’57 Mercury to racing in a low nine-second 99˝ wheelbase, Pinto Pro Stock car, was quite a jump. I was jaded with bracket racing and wanted to run heads up – all out with a door car. So, Pro Stock was it.

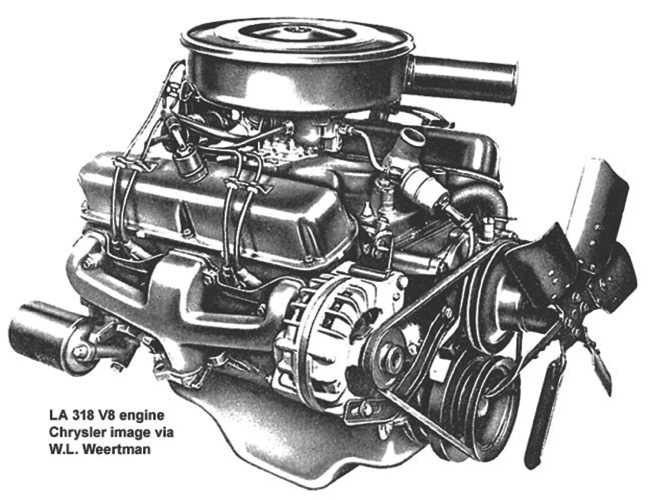

Building a 392 Magnum for the Independence Fund

Ever since the column I did in about stroker motors a few years ago (“Love the One You’re With,” Engine Builder, March 2010), the idea of building one of these engines, a less than everyday stroker combination, has been on my mind. To recap, the premise of the article was simple — Look at the

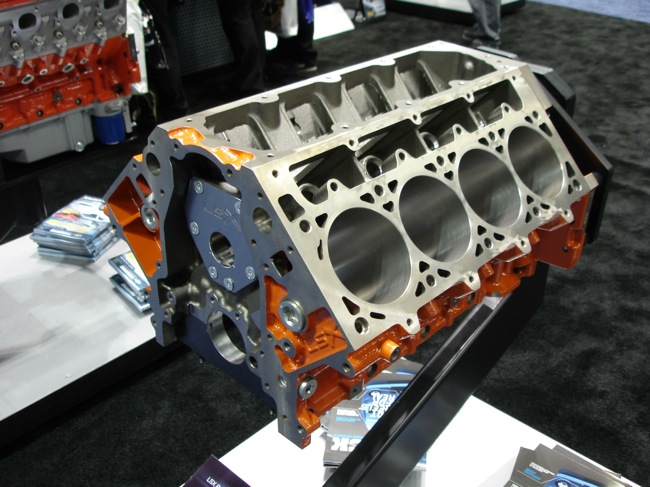

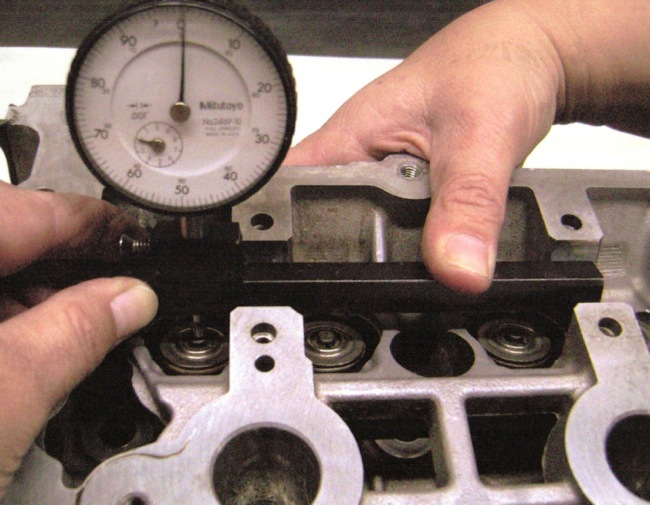

Building Blocks: The Foundation of Any Engine Build

Every engine project starts with the block because the block is the foundation for everything else that follows. The block determines bore and stroke, camshaft and lifter location, oil pump location and oil galley configuration, what kind of main bearing caps can be used to support the crankshaft, and what kind of cylinder heads, oil

Blast From the Past: Learning to Race Pro Stock

My transition in 1975 from bracket racing a 122˝ wheelbase mid-eleven second, two-ton ’57 Mercury to racing in a low nine-second 99˝ wheelbase, Pinto Pro Stock car, was quite a jump. I was jaded with bracket racing and wanted to run heads up – all out with a door car. So, Pro Stock was it.

Advanced Tips for Changing Fuel Pressure on EFI Systems

Changing the fuel pressure on an EFI System is an effective method of affecting engine performance and making more power. However, there are many do’s and don’ts, and rules of thumb that can be frustrating to learn the hard way. Below are many small, but key points, tips and insights all engine tuners should to

December Issue Shop Solutions for Engine Builders

Piston Ring Gapping Tip Some of you may know this ring end gapping tip, but I have never seen it anywhere. Not even in ring package instructions. This has to do with checking the flimsy oil rail gaps. Most conventional size bores are not much of a problem. The rails on those sizes usually have a lot

‘Fine Tuning’ Your Work: Customer Service After the Build

Customer satisfaction is every bit as important as the quality of your work if you expect to be a successful engine builder. You see, even when you build your customer the perfect engine, your customer must be happy with how their engine performs or your business and reputation will suffer. Far too many good engine

A Decade of Dynamic Engine Design – Roush Yates Engines Celebrates 10 Years

In December, Roush Yates Engines (RYE) celebrated its 10th Anniversary and will reset the compass into a new area of the business, but it’s all according to plan. Engine builders who used to see RYE at local races as competitors, will now be able to work directly with them and their vast resources when building

Manifold Matchmaker – Tips for Selecting the Right Manifold for Your Engine Build

Every engine needs some type of intake manifold to route air into the engine’s cylinders. With carbureted engines, the intake manifold has a wet plenum and runners because the manifold has to flow air and atomized fuel at the same time. Consequently, the manifold runners can’t turn or twist too sharply otherwise the heavier fuel

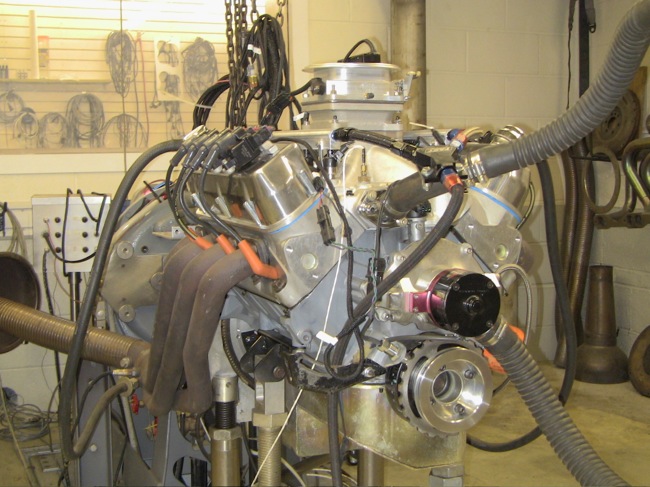

Engine Run Stand Tips

Engine test stands have evolved through development and engineering to help support engine shops, dyno testing facilities and technical trade schools, as well as manufactures. When the topic of dyno testing is tossed around, many think of exhausting every ounce of horsepower and torque. Others focus on profits and cost per hour. This is where a well-engineered engine run stand

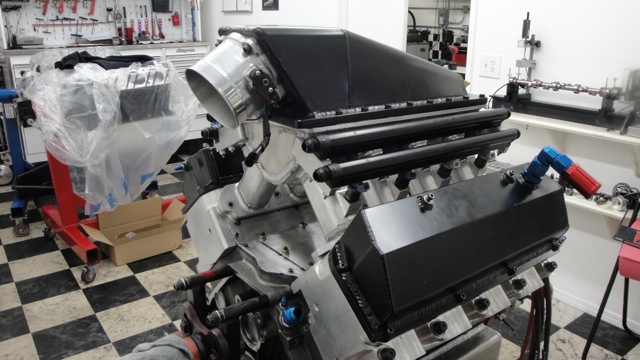

Dyno-Might: Utilizing a Dynamometer to ‘Boost’ Engine Builds

Some would say that one of the criteria for being a “real” performance engine builder is having your own engine dyno. A dynamometer is not just a tool for measuring horsepower and torque (though some people think that’s all a dyno is used for). It’s a quality control tool that allows you to make sure