At the Top of the RPM Range

Craig Haslem first got into the engine building industry while working at a NAPA store in Berea, OH. He worked as a counterman in the late ‘80s and early ‘90s until he was asked to work in the machine shop at the location. After just a week, the guy who brought him into the machine

Not Selling Short – MAR Automotive offers a full package to keep customers satisfied

Jeff Myers was asked to ride his bicycle down the street to meet up with his dad one summer day while he was home after high school graduation. His dad worked next door to an automotive shop owned then, and now, by a man named Tony. Tony ended up giving Jeff a summer job that

Hidden Horsepower – How Simple Machining Steps Can Provide a Win-Win Power Upgrade

In the automotive industry, power and reliability have always been the quest of all engine builders and racers. There are many time-honored methods of increasing horsepower and the same with making engines more reliable. But modifications can sometimes have residual effects and overtax another area of the engine, even compromising reliability. For example, raising compression

Understanding Cylinder Blow-by

While this industry continually runs on tighter and tighter engine clearances, in today’s world of engine building, no one has yet to figure out how to run engine parts on zero clearance. There has to be some amount of space available or an engine simply won’t run. Thus, when it comes to pistons and piston

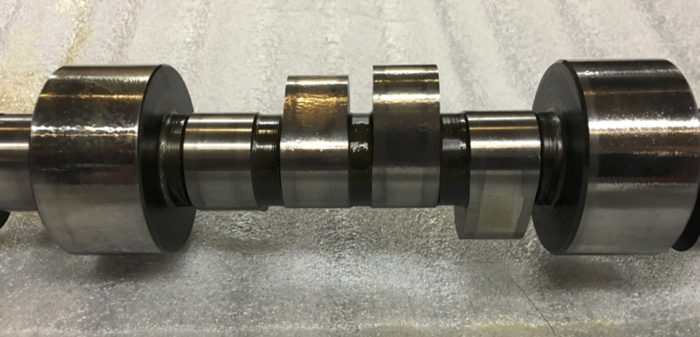

Choosing the Correct Camshaft – Bangin’ on the Bumpstick

There are numerous aspects involved in designing an engine combination. Displacement, compression, airflow, etc., and it is the camshaft’s job to ensure that all of these work together properly to achieve optimum performance. That’s why the cam is often referred to as the “brain” of the engine.

Aviaid Viper Dry Sump System

Aviaid has just released an innovative setup for V-10 Viper applications. The system features a low profile billet aluminum pan with five ports and provisions for mounting the 5-stage (or larger) dry sump pump.

Motovicity Promotes Brett Kinsfather to VP of Sales and Marketing

Motovicity Distribution has announced the promotion of Brett Kinsfather to vice president of sales and marketing, succeeding Brian Lounsberry who was recently promoted to CEO in December 2016.

Ross Racing Pistons Custom Duramax Forged Piston Line

Built from high strength 2618-T61, Ross Pistons has an extensive line of custom, Chevy Duramax forged pistons for 16:5:1 and lower compression ratios.

Holley Universal In-Tank Retrofit Fuel Modules

Holley has announced the release of its all-new Universal In-Tank Retrofit Fuel Modules. Available in both return-style and returnless configurations, these hassle-free fuel modules relieve the burden of converting a factory tank or fuel cell for an in-tank EFI fuel system.

Numbers Don’t Tell The Whole Story

Thankfully, many of YOU took time to give us an inside look at your businesses.

Industry Still Strong, Say Readers

Engine Builder readers tell us business has changed, but opportunity still remains.

Rebuilding the 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would make a great truck engine and could still be used in its cars. This is how the 5.7L Gen III Hemi was born in 2003.

There’s No Simple Formula to Choosing the Perfect Camshaft

The camshaft design affects valve timing, compression and the engine’s ability to breathe. From pistons to manifolds, valve grind, piston pin offset, rod length, etc. Once the camshaft has been tabbed correctly for the application, the rest of the build can focus off that selection.

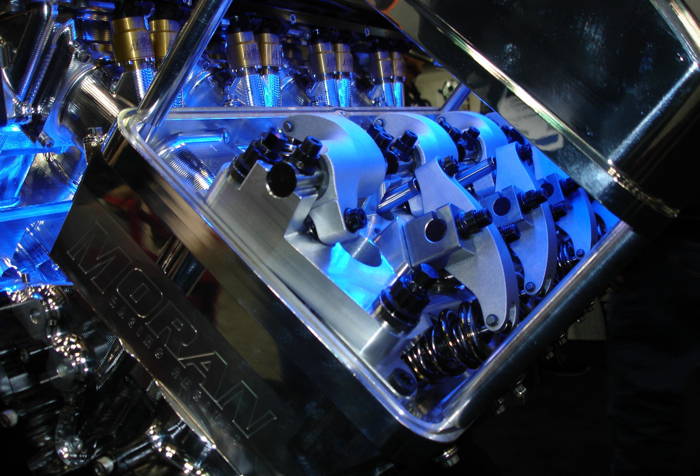

Keep the Valvetrain on Track

The key to choosing the right valvetrain components is to match the parts to the application. It sounds simple enough, yet many valvetrain component suppliers tell us there are a lot of misconceptions about what kind of parts are best for different kinds of performance applications.

Taking On the Internet

According to Engine Builder’s latest Machine Shop Market Profile, 56 percent of our readers don’t use a website for marketing and sales of their services. That needs to change. Here are some helpful tips to get your business into the 21st century.

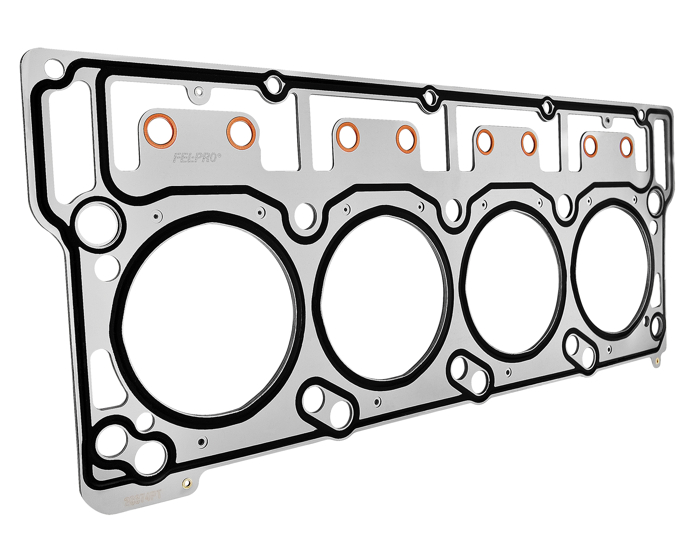

Diesel Performance Head Gaskets

The stock head gaskets that are used in most light truck diesel engines are robust enough to handle peak combustion pressures in the 1800 to 2200 PSI range, but may not do so well at higher pressures if the engine has been tweaked to produce more power.

Camshaft Selection and Design

Choosing the right cam from all of the possibilities that are out there can make a significant difference in how well an engine performs. It’s all about balance and correctly matching the cam with the cylinder heads, compression ratio, intake and exhaust systems, and RPM range where you want the engine to produce the most torque and horsepower.

Forced Induction Facts

Many articles outline the guidelines and basic knowledge to follow when installing some form of a forced induction system. Sometimes you’ll see the “quick and easy way” to upgrade an existing forced induction system, like a turbo, supercharger and/or nitrous oxide system. What if your customer wanted a bigger turbo for a diesel engine or decided to change the pulley size of the supercharger, or maybe use a bigger shot of nitrous on a street car?

More Power Inside – Muscle Cars

There are many aspects of the famous and desired muscle car engines of the 1960s and ‘70s. They have become the holy grail of factory performance engines, but they are getting more and more scarce as the years go by. For car owners, the engines have evolved in recent years into three different configurations. Read on to learn more.

FE Dyno Pulls Show Benefits of Carburetors and EFI

We intended to dyno the engine two ways: first, we wanted to break the engine in and fine-tune it with a carburetor. Then, we would convert the engine over to fuel injection and compare power differences. This would be a great opportunity for a real-world comparison.