Cleaning Cylinder Heads and Blocks

The cleaning process should remove all of the dirt, grease, oil, rust, scale and carbon deposits that have accumulated over the years. With painted castings, the old paint also has to be stripped away so the surface can be repainted. Even if you’re working with brand new castings, a final cleaning is still necessary after

Media and Solutions For Cleaning Engine Parts

One essential aspect of engine building and rebuilding that cannot be avoided is the need for cleaning. Used engine parts have to be cleaned before they can be inspected. Parts that will be reused also have to be cleaned to remove dirt, grease, oil, carbon, rust, scale and other gunk that could contaminate a newly

Cleaning Up In The Shop

In fact, it can be very difficult to make an accurate diagnosis of what’s wrong with an engine until it’s clean. You may be able to recognize some failed parts, you can often see large cracks or obvious damage, but you’re really only assuming you know what caused a failure if you can’t see for

High Tech Cleaning Options

Yet while machining tolerances and performance expectations have changed dramatically over the past few decades, when it comes to getting parts clean, many of those high-tech shops struggle with the same technology they used 30 years ago. The simple fact is, times have changed for parts cleaning, and so have the methods. Engine builders have

Cleaning: Different Methods for Different Needs

Back in the late 1800s, the director of the U.S. Patent Office was said to remark “Everything that can be invented has been invented.” Charles Duell, U.S. Patent Commissioner in 1899 reportedly told the President of the United States that there was no more innovation and, therefore, no more need for the patent office. Except

Cleaning Rules

One of the least pleasant parts of any engine builder’s day is the cleaning process. Removing the oil, carbon and general gunk from blocks, cylinder heads and assorted parts before your inspection, machining and rebuilding process can even begin may seem as painful as a trip to the dentist’s chair. But if you think that

Cylinder Head Cleaning

Being an engine builder is like being a chef. As a master of culinary arts you may prepare the most exquisite meals anyone has ever tasted, but a great dining experience can be easily ruined if the vegetables are not thoroughly cleaned. For more and more engine builders, aqueous cleaning systems are the new standard

Cleaning Engine Parts – In The Real World

Regardless of what kind of engine work you do, cleaning the parts is almost always the first step in any job. Parts need to be cleaned before they are machined for a variety of reasons: it helps keep your shop equipment cleaner (which means less mess and cleanup later), it uncovers the bare metal surface

Aluminum Cleaning & Machining

Steel may still be the big dog when it comes to the content of the world’s motor vehicles, but aluminum usage in cars and trucks continues to increase. Fueled by the desire to save weight, time and energy, aluminum is gaining ground with manufacturers of parts and components. How does the use of aluminum in

Advances in Cleaning Equipment

You could argue that the dishwasher is one of the greatest inventions of the twentieth century. Up until its introduction in households, people had to wash each dish individually, by hand, and dishpan hands were common among women and children. But the dishwasher changed all of that for families, and on its arrival, children everywhere

Aqueous Cleaning Systems Offer Economical, Ecological Benefits

As concern for the environment and worker safety has increased over the years, attention paid to the cleaning processes used in engine rebuilding facilities has sharpened as well. No matter what size the shop, engine components are dirty and need to be cleaned. There are numerous ways to clean parts, of course, and no method

Cleaning Aluminum

"Ten years ago, when there wasn’t that much aluminum, people were scared," said Mike Wigert, sales manager of spraywasher manufacturer LS Industries. "They didn’t know how to regulate their ovens, they didn’t know which chemicals to use, and they were tarnishing their aluminum parts, and probably ended up hand cleaning a lot of them," he

Cleaning – Do You Know Where Your Dollars Are?

Cleaning parts in the machine shop doesn’tcome cheaply. According to Automotive Rebuilder’s Machine ShopMarket Profile about 15.2% of engine machining and rebuildingproduction work involves disassembly and cleaning. According torebuilders that we surveyed, disassembly and cleaning accountedfor the highest percentage of total rebuilding production timein the shop. So there can be significant benefits to reducingcleaning costs

The Nitty Gritty On Small Parts Cleaning: Many Ways To Clean Small Engine Parts

Tom Nichols, CEO and president of AutomotiveMachine & Supply, Inc., Fort Worth, TX, said availabilityis most often the key to why his shop cleans and reuses smallparts. Nichols said each day his shop cleans and reuses many smallparts, including valve locks, shims, springs, retainers, rockerarm assemblies, cam bore caps, nuts, bolts, etc. "Becausewe only

Component Cleanliness

It can’t be overstated how important the cleaning machines are in the modern engine shop. Shop owners who prioritize effective and efficient cleaning techniques will find success in a more streamlined process.

Graymills’ SuperSonic Liftkleen Parts Washer

Unlike standard spray cabinet washers, immersion cleaning exposes all surfaces of the part, including blind holes and small crevices, to the cleaning solution.

Graymills TUSR-Series Sonic Liftkleen

Unlike standard spray cabinet washers, immersion cleaning exposes all surfaces of the part, including blind holes and small crevices, to the cleaning solution.

1,000 HP 426 cid Hemi Engine

While Dodge got creative with its Hellcat, Demon and Hellephant engine names, MTI Racing hasn’t named this 426 cid Hemi package, but something tells us that won’t hold this engine back from being a popular option! Find out what goes into this special build.

Fuel Injector Selection & Service

These days just about everything is computer controlled, and we mean EVERYTHING. But the only kind of electronics we’re interested in for this article is one of the oldest computer-controlled engine parts around – the humble fuel injector.

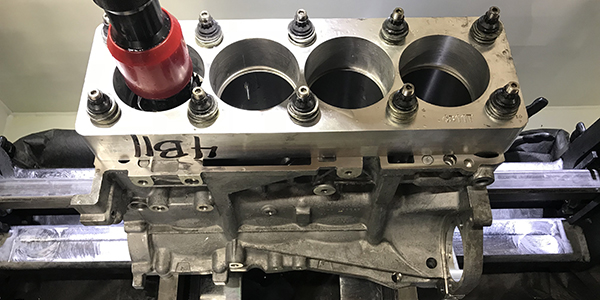

4B11 Mitsubishi Evo Engine

The first 4B11 engine that ever came into AR Fabrication was there for a set of Darton MID sleeves. Since then, many 4B11 blocks have made their way through the Winchester, VA-based shop. This particular 4B11 was built for Moore Automotive. Find out what work went into the build, and how it affected the engine’s performance.