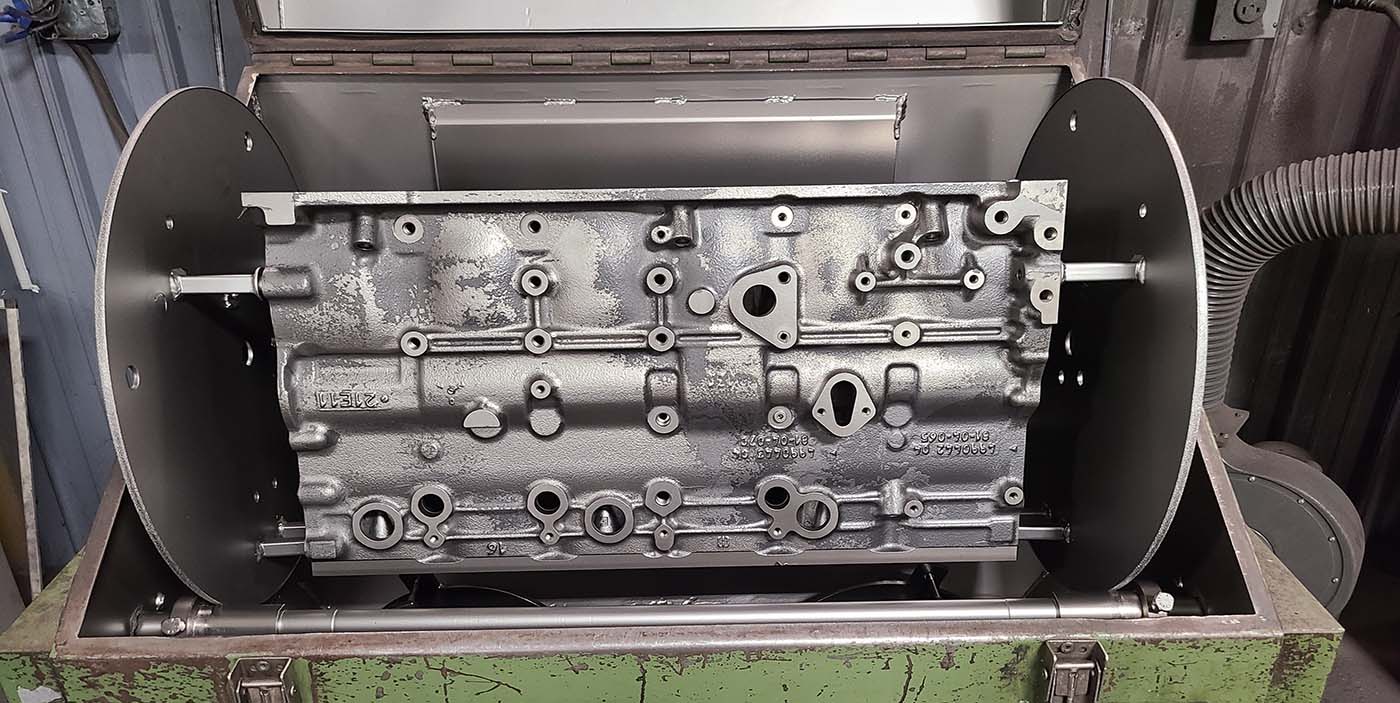

Graymills CTU SonicMAX Ultrasonic Cleaning System

The console’s small footprint make these units ideal for job site “cell” cleaning applications or where space is critical.

Ultrasonic Cleaning

The technology remains an excellent cleaning option for machine shops and engine builders looking for cleaning equipment.

Ultrasonic Cleaning

From cleaning to machining, engine builders are leaving the hands-on approach behind in favor of more automated methods that are also more friendly to the environment. If you’re looking for a system that works as good as some of your methods, ultrasonic cleaning might be a good choice for your shop.

Ultrasonic Cleaning Technology

Ultrasonic cleaning is one of the ways engine builders can choose to clean parts, but what is it and how does it work? Is it the too-good-to-be-true stuff of science fiction or is it the best technique ever for cleaning the dirtiest of engine components? The truth, as they say, lies somewhere in the middle.

Ultrasonic Mobile Cleaning Units

Ultrasonic cleaning is extremely effective at removing dirt and grime from even the smallest of crevices

UltraSonic Ultra 1000M Cleaning Machine

The Ultra 1000M fits conveniently on your tabletop and delivers high-performance, precision-clean results that save hours of labor compared to other methods.

UltraSonic LLC Ultra 3800FLT Cleaning Machine

Featuring a lift table, 38.5˝ tank length, low profile ergonomic design, and dual programmable automated cycles, the Ultra 3800FLT was specifically engineered to be a cost-effective way to clean.

Graymills BTU Series Digital Ultrasonic Benchtop Washers

Small footprints make these units ideal for job site “cell” cleaning applications or where space is critical.

UltraSonic Products Now Available from Goodson

Goodson now offers UltraSonic LLC cleaning machines and supplies. These items are stocked and shipped from UltraSonic LLC to your location. WHY ULTRASONIC CLEANING? Cleaner parts at lower cost The power of cavitation — attacks contaminants in hard-to-reach areas Increased lifespan for clean parts. Well maintained parts are likely to last longer and perform better

Cleaning Equipment in Today’s Shops

Keeping components and parts in your shop clean is of utmost importance, second only to washing your hands.

Cleaning Components with Baking Soda

There are many different processes for cleaning parts and components before engines can be rebuilt, and engine builders use a variety of cleaning solutions for different reasons. However, the argument can be made that sodium bicarbonate blasting or soda blasting has numerous advantages.

Engine Part Cleaning Tips and Techniques

It’s not fun, but vital to successful rebuilds According to a recent Engine Builder Machine Shop Market Profile, in which we survey hundreds of machine shops across the country, about 15 percent of the total production time for rebuilding an engine is spent in the cleaning process. While our wives may not agree that we

UltraSonic Launches New Website

UltraSonic LLC has announced the launch of its new website, www.ultrasonicllc.com. The new site provides fast and easy access to comprehensive information about the complete line of tabletop, mobile and lift table ultrasonic cleaning machines.

Safe Cleaning – Are the Concepts Compatible?

The subject of cleaning is never far from the mind of the modern engine builder or machine shop supervisor. Obviously, parts must be as clean as possible so they can be inspected, repaired if possible and reassembled. The subject of SAFE cleaning is a little less definitive, however.

Chemical Cleaning – Solvents and Aqueous Products Are Still Popular Choices: Here’s Why They Work

Cleaning is a process that no engine builder can avoid, whether you are rebuilding high mileage engines caked with gunk and full of gunk, or you are working with all brand new components and castings.

Cleaning Engine Parts

Cleaning is a time consuming, expensive process for most rebuilders. According to Engine Builder’s most recent Machine Shop Market Profile, rebuilders say they spend more than 15 percent of their total production time in cleaning. Safer, less toxic methods continue to gain a foothold in today’s professional shops.

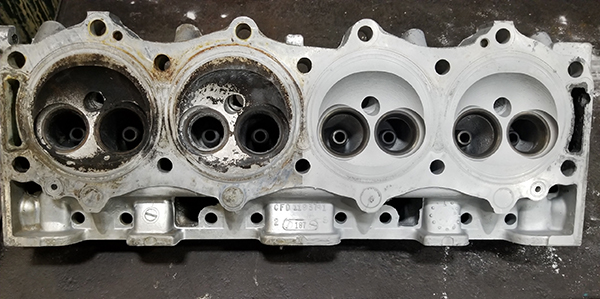

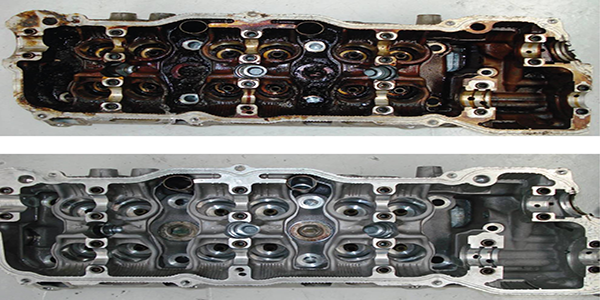

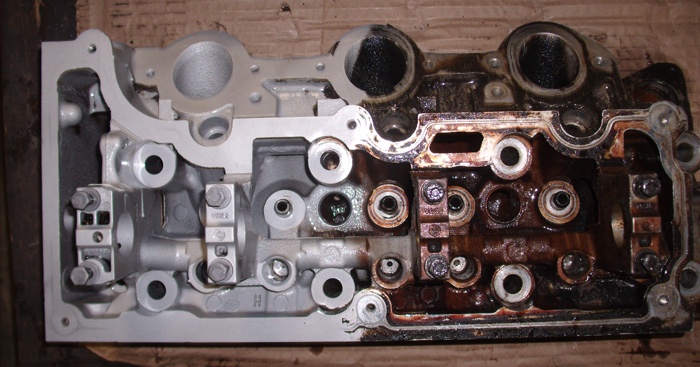

Cleaning Engine Blocks & Engine Cylinder Heads

Cleaning engine blocks and cylinder heads is just as important as the machining operations you will perform on the castings. You can’t do a thorough job of inspecting these parts if they are dirty, greasy or covered with paint or corrosion. Checking for cracks in cast iron heads and blocks requires a clean surface for

Green Strategies: Cleaning Techniques & Equipment

It may seem that there’s nothing natural about cleaning an engine. Even after the couple of hours of cleaning time, the engine might be cleaner than the tech working on it – but the engine still needs cleaned (and so does the cleaning crew from time to time). We are long from the days of

Cleaning Engine Parts: Can You? Should You?

Here’s the kicker – those shops who feel that proper cleaning is too difficult, too time consuming or too expensive are actually leaving money on table when it comes to their engine parts. “At one point in my career, cleaning seemed like it was really difficult,” says Dave Arce of Arce Enterprises, El Cajon, CA.

Making Dollars and Sense Cleaning Blocks, Heads

Unless you’re starting with all new parts, cleaning is as important to your engine build as disassembly, inspection, machining and reassembly. Without taking the cylinder heads and engine blocks down to bare metal, you can’t properly inspect the castings for cracks, wear and other defects. For something so important, proper cleaning technique is often misunderstood, overlooked