Third-World Problems, First-World Production

Ask the typical reader of Engine Builder what his biggest business challenge is and you might hear complaints such as bargain basement internet parts sales, competition from OEMs and an inability to find enthusiastic employees. Ask Andrew Yorke about his headaches and things sound a bit different. “Things that all my fellow engineers take for

Spick-and-Span

As engine technology continues to evolve, so have the cleaning processes for removing dirt, grease, oil, hard carbon deposits, rust, scale, corrosion and discoloration from engine castings and components. Several factors make cleaning more challenging today.

Today

Although extremely important, the job of cleaning engine parts leaves nothing to the imagination. You’re idly standing with a spray gun in your hand or beside a washer tank or cabinet. It’s a basic, time-consuming procedure, but that grime, oil and baked-on sludge won’t come off by itself. This necessary evil is the difference

BIG R Show to Feature Seminars from RIT’s Reman Center

Automotive parts remanufacturing is becoming more competitive every year. Progressive remanufacturers are always looking for new ways to save money through process improvements. Surface cleaning is one step inthe remanufacturing process where companies can typically find improvement opportunities due to the ever-increasing number of new chemistries and technologies available. Once identified, how does a company

HPBG: Engine Builder Fuel Injection Maintenance

The fuel system of a modern computer-controlled fuel injected engine is so reliable that it seems to be almost maintenance free, but these modern fuel injected engines have injectors that become flow restricted or “dirty” with use. This means that if you expect the engine you build to perform like it should, the fuel injectors

A Million Here, A Million There

First, Fisher’s a former winning sprint car driver running with the top-gun World of Outlaws and All-Star groups. Then, there’s the fact that he’s got the mind of a skilled surgeon when he probes the innards of his engines looking for more performance. The guy is a graduate engineer (Ohio State – 1975), but his

PERA’s Core Corner, Fighting Truth Decay About Cavitation Damage

It’s amazing how something that may be damaging or corrosive in one circumstance can be of great value in another, like using extremely dangerous explosives to put out an oil well fire. This month we are going to talk about a similar action yet on a much smaller scale, microscopic actually, and it’s called “cavitation.”

Searching For The Complete Clean

Many shops have systems that work well for one but not so well on the other. Are there effective ways to clean both types of metal with one setup? The answer to that depends, in large part, on what you consider clean. Most shops have some type of cleaning equipment, whether it is an automated

Shop Solutions January 2021

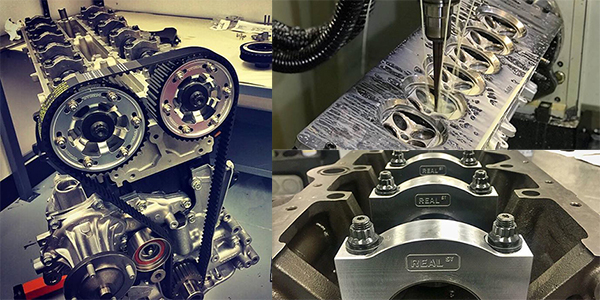

QUICK DRILL CLAMP A very handy drill press clamp set can be made in about 15 minutes from 1˝ angle iron, two carriage head bolts (they fit the t-slots), a couple valve guides for spacers, and two wing nuts. It has a wide operating range and is very quick and easy to adjust or remove

Parts Tumblers

Like most equipment, what kind of tumbler and how many a shop needs depends on what a particular shop is looking to achieve.

Engine Components: Getting a Good Clean

There are few things that can rejuvenate you like a good, hot shower. I can only imagine how awful it must have been a few hundred years ago having to bathe in stale, tepid water out of a small tub no less. And, you’d only do that maybe once a week! I’m certainly thankful I

416 cid Twin-Turbo LT1 Engine

In its 50-year history, Pro Car Associates has done it all when it comes to automotive work and engine work. Now in the capable hands of Chris Wright, Pro Car continues its quality work on builds like this 416 cid twin-turbo LT1 engine for a 2016 Camaro SS. Find out how much horsepower this beast cranks out!

Sodium Bicarbonate – A User-Friendly Blasting Abrasive

Sodium bicarbonate blasting or soda blasting, is a user-friendly process for the removal of grease, oil, burnt carbon and many other contaminates experienced in engine building. There are many different processes for cleaning parts and components before engines can be rebuilt, however they are not all equal.

Turbocharged Toyota 2JZ Engine

When this turbocharged Toyota 2JZ engine got on the dyno at Victory Precision Machine, it lost oil pressure. The problem turned out to be a spun bearing and a trashed crank. Frank Mangano got to work rebuilding this engine for a 1997 Supra street application. Find out how the build turned out!

Revved Up – Why the Import Engine Market is on the Rise

For numerous reasons in recent years people have been fixing engine issues rather than replacing engines altogether, making for a strong outlook in the import engine market. There are several ways you can break into this market or improve your stance here if you’re already an import engine builder.

November 2014 Shop Solutions

One of the main problems with blocks that need to be align-bored is the lack of squish between the main cap and the block. What I am referring to is the interference fit between the cap and main register that holds the cap in alignment, and is the reason a light tap is needed to seat the cap. If the caps do not fit tight, the crank will not be held as solidly as it was intended, and also results in inconsistent bearing clearances.

Must Have Shop Tools & Measuring Equipment

You can’t do quality work in an automotive machine shop if you don’t have the right tools and measuring equipment. “Must have” tools and equipment include those that are necessary for engine disassembly, for inspecting and measuring engine components, and for engine assembly.

Green Strategies: Recycling Options for the Engine Shop

Recycle or dispose. What’s the difference? It’s just trash, right? Not really. The old adage of “one man’s trash is another man’s treasure” profoundly rings true in automotive aftermarket’s own recycling niché: engine building. We know you set aside your metals from a wide range of vehicle repairs and modifications, but when it comes to

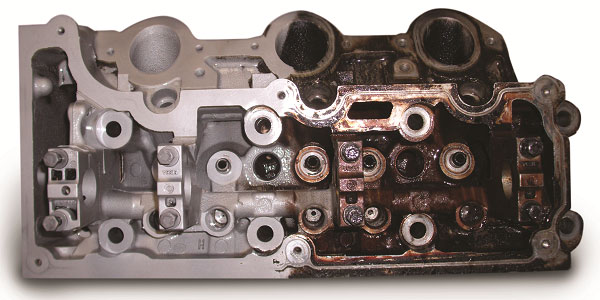

OHC Cylinder Head Rebuilding and Equipment

Originally featured mainly in European racing machinery from Fiat, Peugeot and Alfa Romeo in the early part of last century, by the 1960s companies like Fiat and Jaguar had introduced OHC production engines. It was advanced technology for the time, but today OHC is the norm for even the least expensive production engine. OHC cylinder

TIG Welding Aluminum Heads

To survive in the current economic climate, you must look for opportunities to become more profitable and still maintain control of your profits. You must always look for ways to keep more of what you do “in-house” and keep as much of the revenue you generate in the business. Whenever you can control what goes