Centroid Announces its A590 5-Axis Engine Shop Machining Center

A new level of 5-axis CNC machining performance and price point is found in the Centroid A590 5-axis Engine Shop machining center. Create billet blocks and heads and CNC port and blue print Diesel blocks and heads faster than ever before.

Why Cutting Fluids Are Imperative to Machining

In order to produce the best performing engines with tight tolerances and finishes, CNC machines require cutting fluids to perform at the highest levels. You might think a fluid is a fluid is a fluid, but you’d be wrong.

Centroid A590 5-Axis Machining Center

Centroid has introduced a new level of 5-axis CNC machining performance and price point with its A590 5-axis engine shop machining center. Create billet blocks and heads and CNC port and blue print diesel blocks and heads faster than ever before.

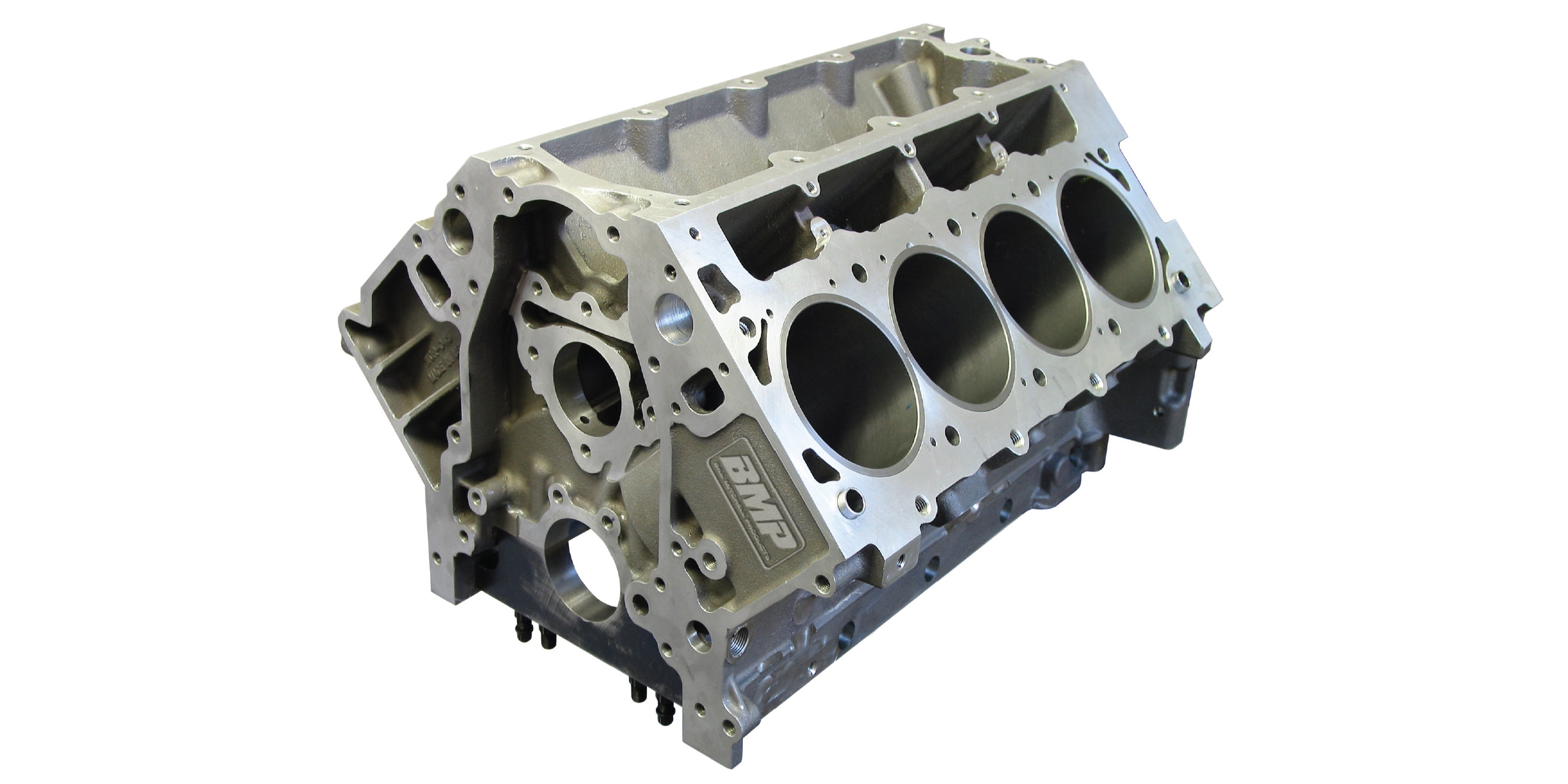

Machining Aluminum Engine Blocks

Aluminum engine blocks have been around for many years for both stock and performance applications. Aluminum has a number of advantages over cast iron, the most obvious one being weight.

Hidden Horsepower – How Simple Machining Steps Can Provide a Win-Win Power Upgrade

In the automotive industry, power and reliability have always been the quest of all engine builders and racers. There are many time-honored methods of increasing horsepower and the same with making engines more reliable. But modifications can sometimes have residual effects and overtax another area of the engine, even compromising reliability. For example, raising compression

Comau SmartDriveComau 800L Horizontal Machining Center

SmartDriveComau 800L is a horizontal machining center that covers primary manufacturing needs, both as a single machining center or integrated within a highly flexible production line. This powerful machine, the latest from Comau Powertrain Machining & Assembly, is the new generation model.

Modern Machining

Advancements in engine machining technology have truly moved this industry firmly into the space age. Highly developed abrasives and computer numeric controlled (CNC) software are found at almost every level of equipment, leaving some to mourn the loss of the “art” of engine machining in favor of the “science” of precision.

2010 Performance Machining & Engine Parts Guide

(Download and view the .pdf here) Sponsored By:

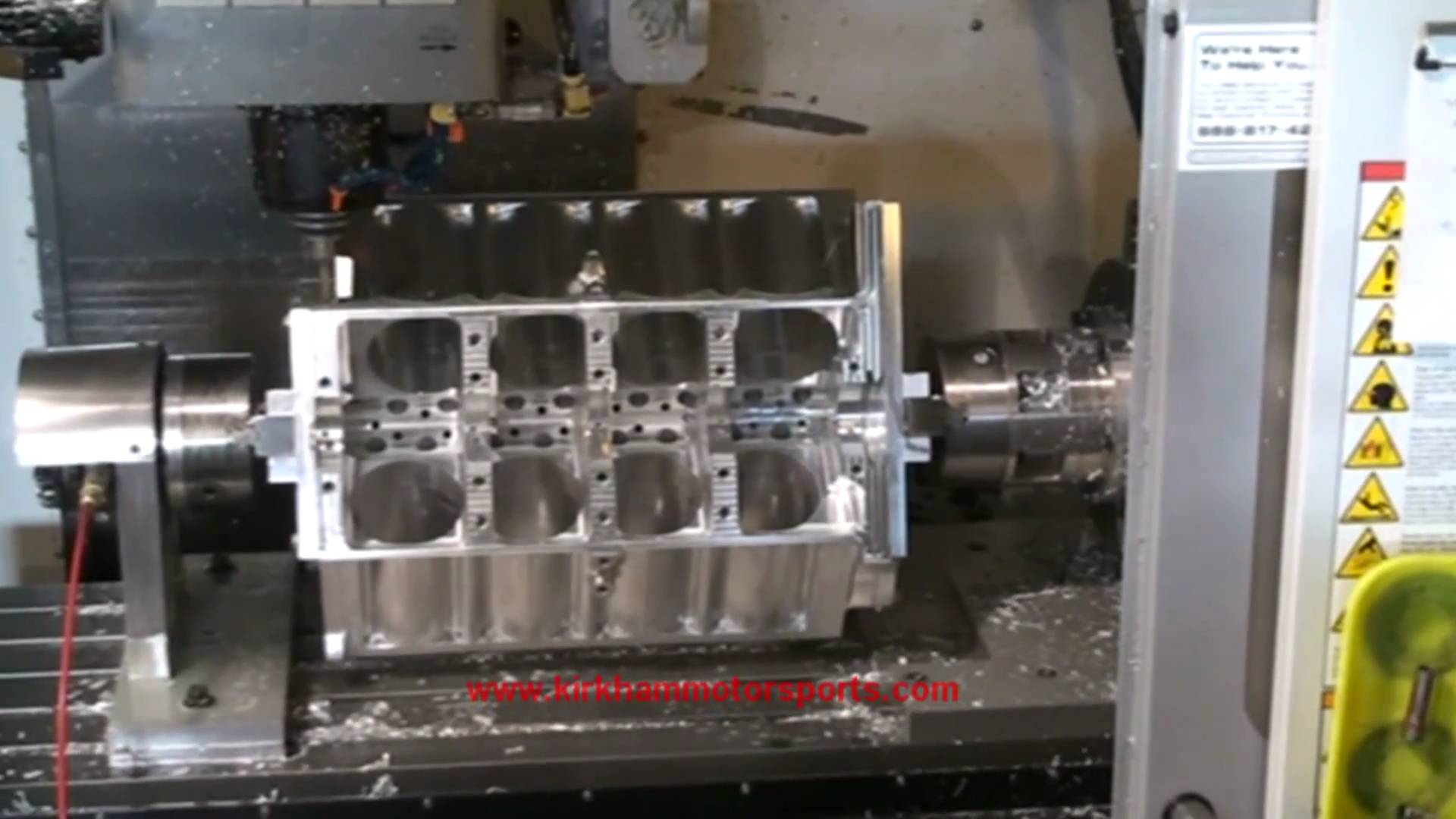

427 FE Engine Block Machining from Solid Aluminum

Kirkham Motorsports shows how it took a solid, 386-lbs. block of aluminum and machined it into a 427 FE engine block. Company: Kirkham Motorsports www.KirkhamMotorsports.com

Future of Engine Building: The Road Ahead for Machining

The future always seemed so far away for some reason. You had cartoons featuring flying cars and movies about aliens and galaxies far, far away.

Combo 5-axis CNC Cylinder Head & Block Machining Center

CNC port cylinder heads, blueprint and CNC machine engine blocks and make all kinds of parts with one machine the Centroid A560. See the machine in action porting cylinder heads and machining blocks. Company: Centroid http://centroidperformanceracing.com

Cold Air Tool Cooling For Machining (#9)

Cold Air Guns use a small amount of filtered compressed air and vortex tube technology to produce sub-freezing air for numerous cooling applications. Without any moving parts to wear out, the internal vortex tube converts shop compressed air into a cold air stream, producing temperatures down to as low as -30 degrees F. Visit the

CNC Machining Advantages

Running a profitable machine shop these days requires a lot of things: skilled machinists who know what they are doing, accurate equipment that can perform all of the tasks that are required to machine cylinder heads and blocks, an efficient work environment that maximizes both shop labor and equipment usage to boost productivity, a commitment

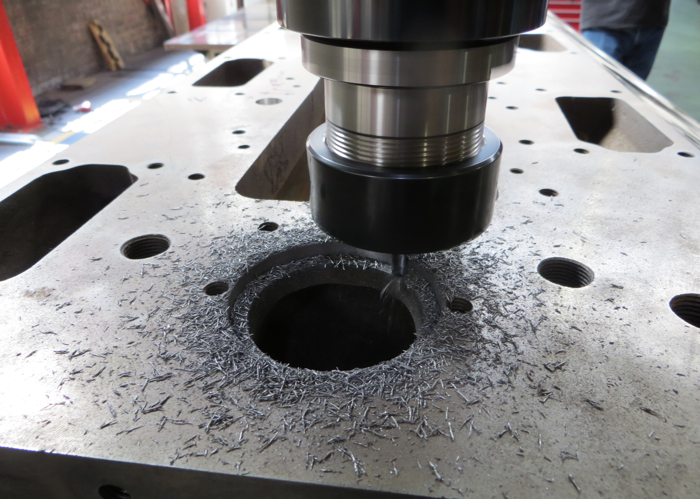

Cylinder Bores-Machining To Sleeving

The function of a cylinder bore is fairly simple yet quite demanding. The bore is nothing more than a cylindrical void which contains the engine’s air/fuel mixture as it undergoes compression and combustion. The walls of the cylinder have to be strong enough and rigid enough to withstand high combustion pressures and temperatures

Gasket Surface Machining is Critical to Cylinder Head Repair

According to this representative, the relatively short production life of modern engines also shortens the time that an aftermarket gasket company needs to remedy application-specific cylinder head sealing problems. Another issue is that, if the company develops a superior gasket sealing design for specific applications, the engine might disappear from the market before the company’s

AERA Announces Engine Rebuilding, Machining Certificate Program

Rather than a test to prove understanding, AERA has chosen to offer a comprehensive online training program leading to diploma-quality certificates in Cylinder Heads and Engine Machining. Technicians who successfully earn either certificate will hold proof that they have an elevated understanding of fundamentals of machining, measuring tools, shop safety, fasteners, engine theory, engine diagnosis,

2010 Performance Machining & Engine Parts Guide

(Download and view the .pdf here) Sponsored by:

CNC?Head Porting & Machining Centers

The fact that CNC machines have come down in price over the years, coupled with less complicated interfacing systems means that today they can be used by nearly anyone. You don’t have to relearn everything. You don’t have to take endless courses on how to make a tool change. Today’s machines are sophisticated and savvy

Valve Seat Selection and Machining

When rebuilding a cylinder head for a stock automotive application, a performance engine, or a heavy-duty diesel, what kind of replacement seats should you use if the original valve seats need to be replaced? Should you install new seats that are the same as the original seats, or should you use a different type of