MSD All-New Black Pro Power Coils For LS Engines

Holley/MSD has announced the expansion of its line of high-performance multiple-spark coils with all-new coils for GM LS engines. They bolt right in to the factory coil location and feature direct-plug connectors to OE harnesses for a fast, hassle-free installation.

Honda Marine and H2O Sports Manufacturing Announce New Agreement

Honda Marine, a division of American Honda Motor Co., Inc., and H2O Sports Manufacturing, LLC announced a new agreement to revive the Trophy brand boat to be powered exclusively by Honda Marine engines. Honda Marine is a marketer of a complete range of outboard marine 4-stroke engines.

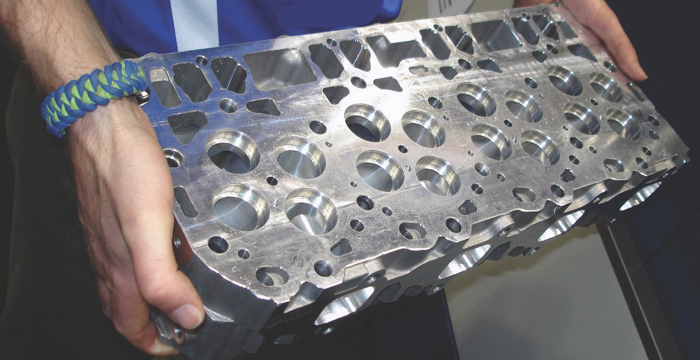

Cylinder Head Design, Selection for Engine Builds

Choosing the “right” cylinder heads for an engine build can make all the difference in an engine that delivers and one that falls short of its potential. Horsepower, torque and throttle response all depend on how well the cylinder heads, camshaft and induction system work together. Choose the right combination and you’ll build a winner.

Valve Timing Events and the Order of Importance

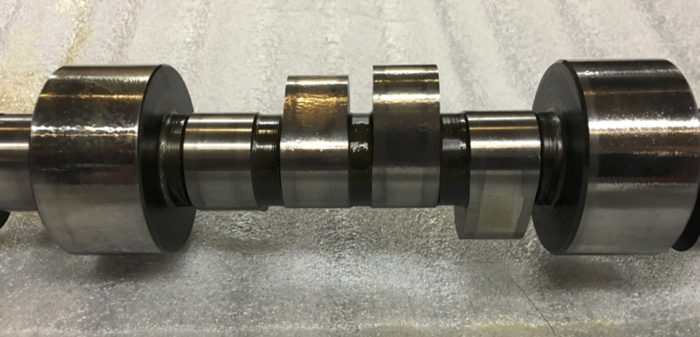

If you’ll recall, in the January issue, we got into the nitty gritty details of what makes a camshaft the “right” camshaft. In this issue, we’ll continue the education. Cam class is back in session!

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

Understanding How to Tune Carburetors

An engine only runs as well as it is tuned. You can build a killer motor using all the best parts and machine and assemble everything with the utmost care, but if it’s a carbureted engine and the carburetor isn’t set up or tuned right your killer engine may never live up to its full potential.

Motor State Distributing Adds Daytona Sensors

Motor State Distributing has announced the addition of Daytona Sensors product line to its brand selection of automotive engine management control systems.

There’s No Simple Formula to Choosing the Perfect Camshaft

The camshaft design affects valve timing, compression and the engine’s ability to breathe. From pistons to manifolds, valve grind, piston pin offset, rod length, etc. Once the camshaft has been tabbed correctly for the application, the rest of the build can focus off that selection.

AutoMeter Pro Plus Wideband Gauges

AutoMeter has introduced its PRO Plus Wideband Gauges. Knowing the exact air/fuel mixture running through your engine is the most important factor to extracting the highest levels of performance and durability.

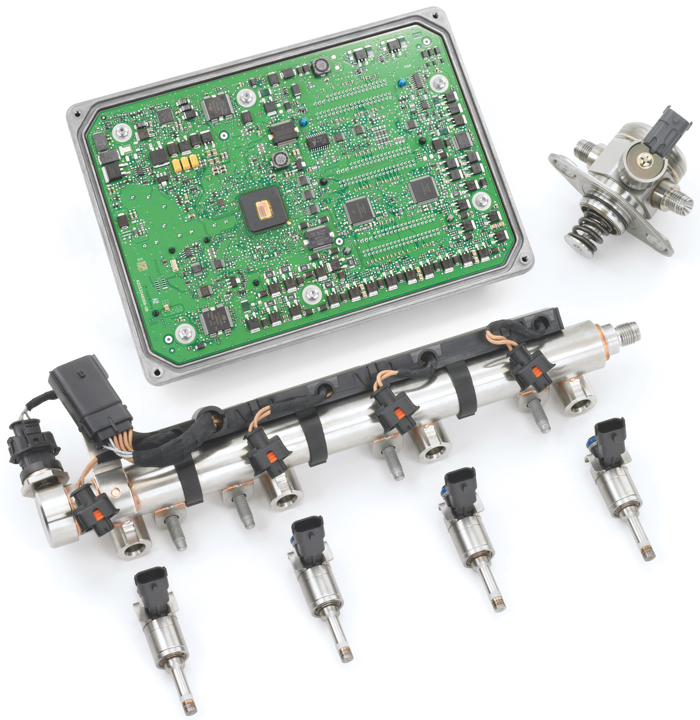

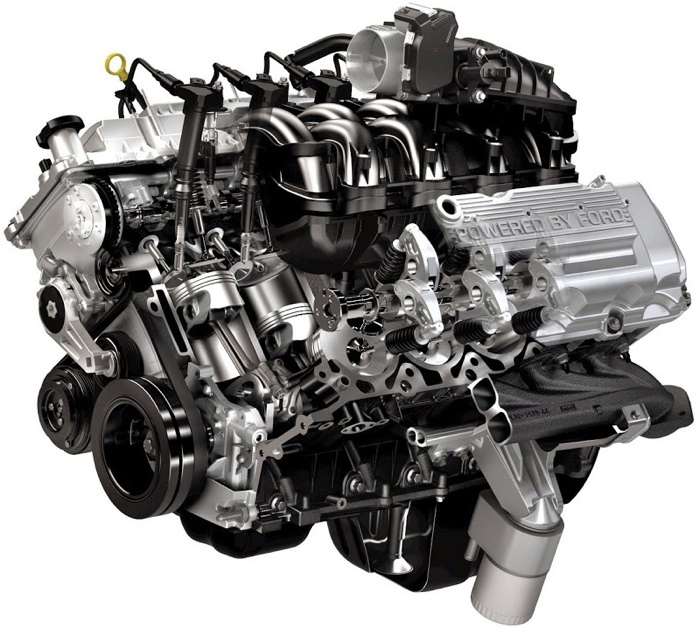

Direct Injection Gas and Diesel Technology

Direct injection is becoming standard on more and more late-model vehicles in both gasoline and diesel versions. These systems can be a diagnostic challenge, but with the right foundation, problems can be solved profitably. A better understanding of how they work can help you help your installer customers do a better job.

Carburetor and EFI Conversions

Carburetors have long served the performance aftermarket and racing industry well. Although they disappeared from new vehicles back in the late 1980s to meet emission requirements, it was only a couple of years ago that NASCAR finally abandoned carburetors in favor of fuel injection.

Performance V6 and Four Bangers

Any engine builder worth his or her torque wrench keeps their eyes open. They’re looking for anything and everything to make work easier, better and, of course, more profitable. When it comes to the number of cylinders in the motors they build, are they looking at performance-dedicated six and four cylinder engines as a viable source of income?

High Performance Diesel Crankshafts, Connecting Rods & Pistons

Most stock Cummins, Duramax and Power Stroke engines can safely handle cranking up the turbo boost to produce 500 to 600 or more horsepower. But once you get to get up around 700 to 800 horsepower in an otherwise stock motor, things start to break and upgrades will be necessary.

CNG and Propane Engine Builds

Building engines for a living means building whatever a customer wants. With a growing market for alternative fuels you might find yourself building an engine for a customer who wants his engine to run on compressed natural gas (CNG), liquefied natural gas (LNG) or propane (liquefied petroleum gas or LP).

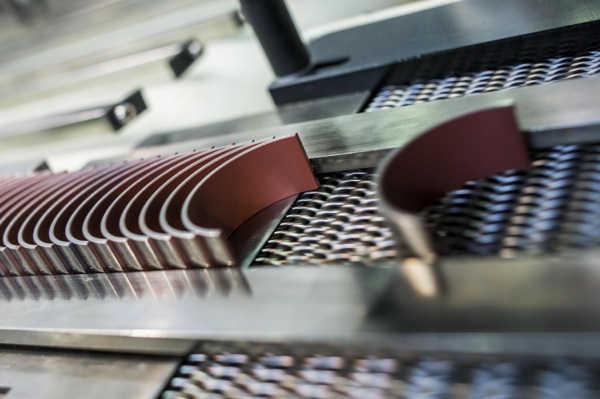

Parts Coatings

Whether it’s more horsepower, better throttle response, or better durability, everybody is looking for an edge when it comes to building a performance engine. Any of these can win races. So what kinds of tricks are winning engine builders using to get an edge over their competitors? Many are using highly specialized coatings.

What Does Ethanol Mean To Your Shop?

Although ethanol alcohol is mostly made from corn, it seems to be a real hot potato! Almost all pump gasoline today contains 10 percent ethanol (E10) because the Renewable Fuels Standard Act requires it. The reasons why are partially practical, partially political and partially economic.

New Engines Force New Pistons

As engines get smaller, motorists expect the same performance as a larger V6 or V8 but with the fuel economy of a four cylinder. Turbocharging makes little engines breathe big, but it also increases the load and temperature the pistons have to endure. This, in turn, requires pistons made of alloys that can withstand higher temperatures and combustion pressures. Yesterday’s castings won’t cut it for these kinds of applications.

Choosing the Right Camshaft for a Performance Engine

A camshaft is nothing more than a cast iron or steel shaft with a series of lobes strategically placed along its length. Each lobe opens and closes a valve by moving a lifter, pushrod and rocker arm, or in the case of an overhead cam engine by moving a cam follower or direct valve action. However, choosing the right camshaft is not only the cornerstone of building a performance engine, but also its centerpiece.

Direct Injection Engines and Carbon Deposits

When the early direct-injection engines hit the three-year or 30,000-mile mark, some developed driveablity problems due to carbon buildup on the necks of the intake valves. In the late ‘90s and early 2000s, TSBs related to carbon deposits on the valves were few and far between. There are three reasons why direct-injection engines are more prone to carbon deposits. Read on to find out.

The Evolution of Surface Treatments

In the never ending quest for better performance, durability and reliability, various types of surface coatings and treatments have evolved as solutions for problems that have vexed engine builders for years. Coatings that were once considered exotic race-only solutions are now being used on a wide variety of stock and performance applications. If you’re not