Visit Lake George and Performance Marine

Today, Performance Marine is a full-service repair facility, offering a number of boating services and also includes the company’s high-performance business known as Saris Racing Engines.

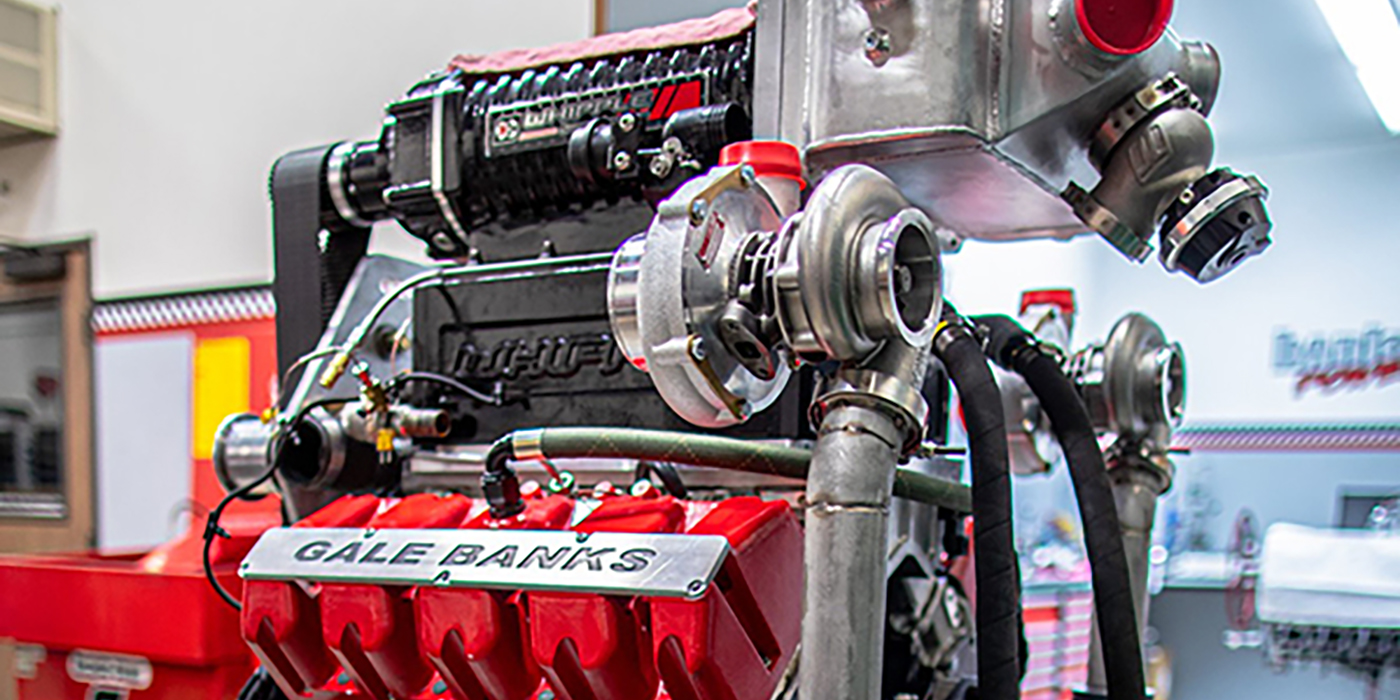

Supercharged Twin-Turbo 427 cid 7.1L Duramax

Gale Banks and his team have been hard at work building a diesel equivalent monster truck engine that delivers horsepower and throttle response as good or better than Monster Jam’s current 540 cid big block Chevy blown alcohol engines. Find out what their supercharged twin-turbo 427 cid 7.1L Duramax is capable of.

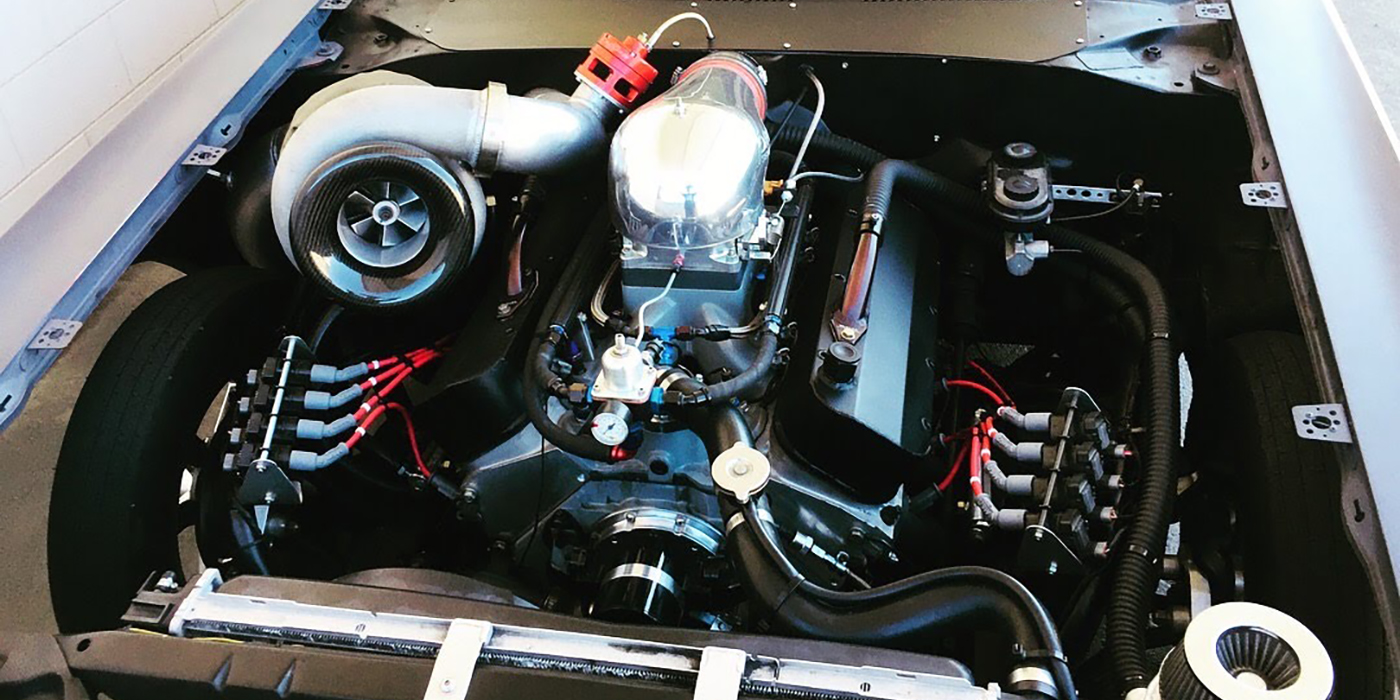

Turbocharged Gen V 454 cid Big Block Chevy

After building more than 700 engines in his career, Joshua Gomez of MotorVation Performance, wanted to build himself an engine that was affordable, fast and stayed together. He hot rodded this 454 cid Gen V big block Chevy to the tune of 1,800 horsepower. Find out what went into the build!

Electronic Fuel Injection for the Masses

There’s no way to sugar coat it. Unless you’ve got a rock-solid niche business in building vintage engines, chances are you’ll need to become an expert with EFI products and how to tune engines with these systems.

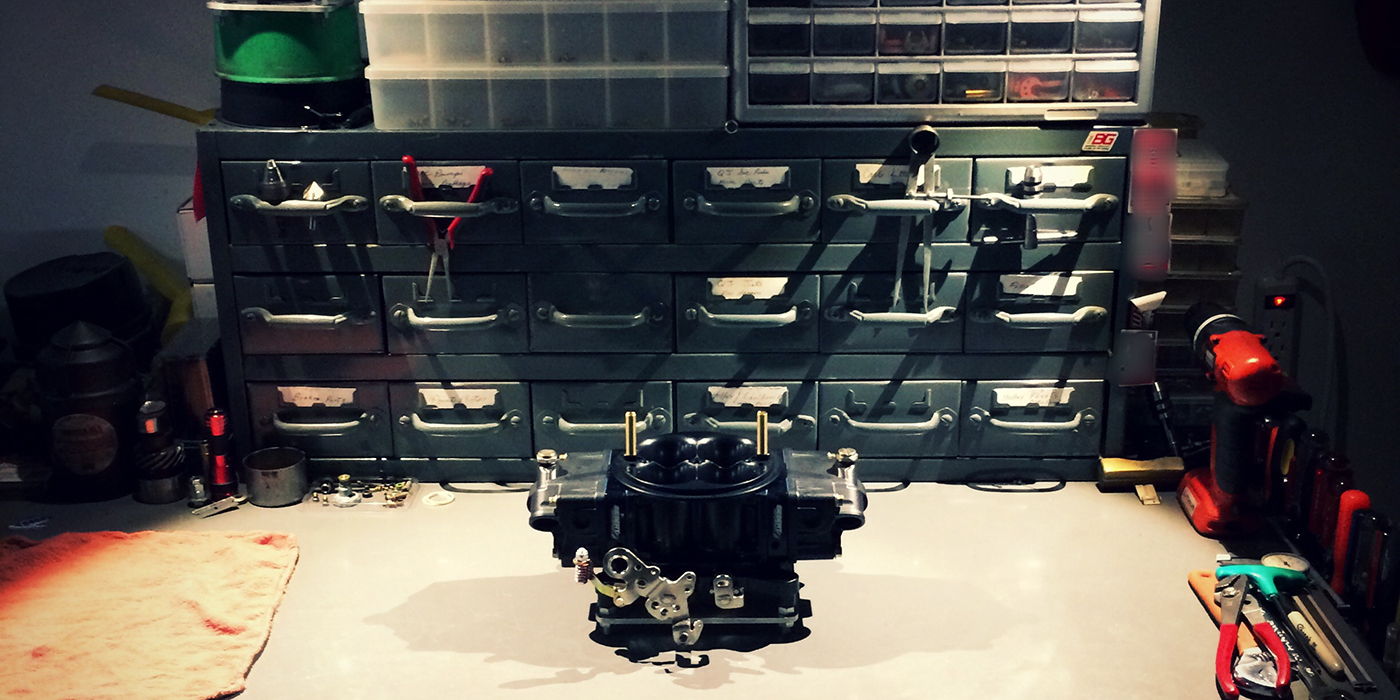

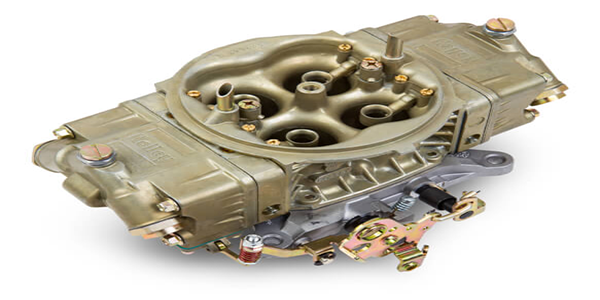

Are Carburetors Dead?

The carburetor market has evolved right along with the ever-changing technology that surrounds it, driven by the need to stay relevant and remain a viable option for those looking to win races.

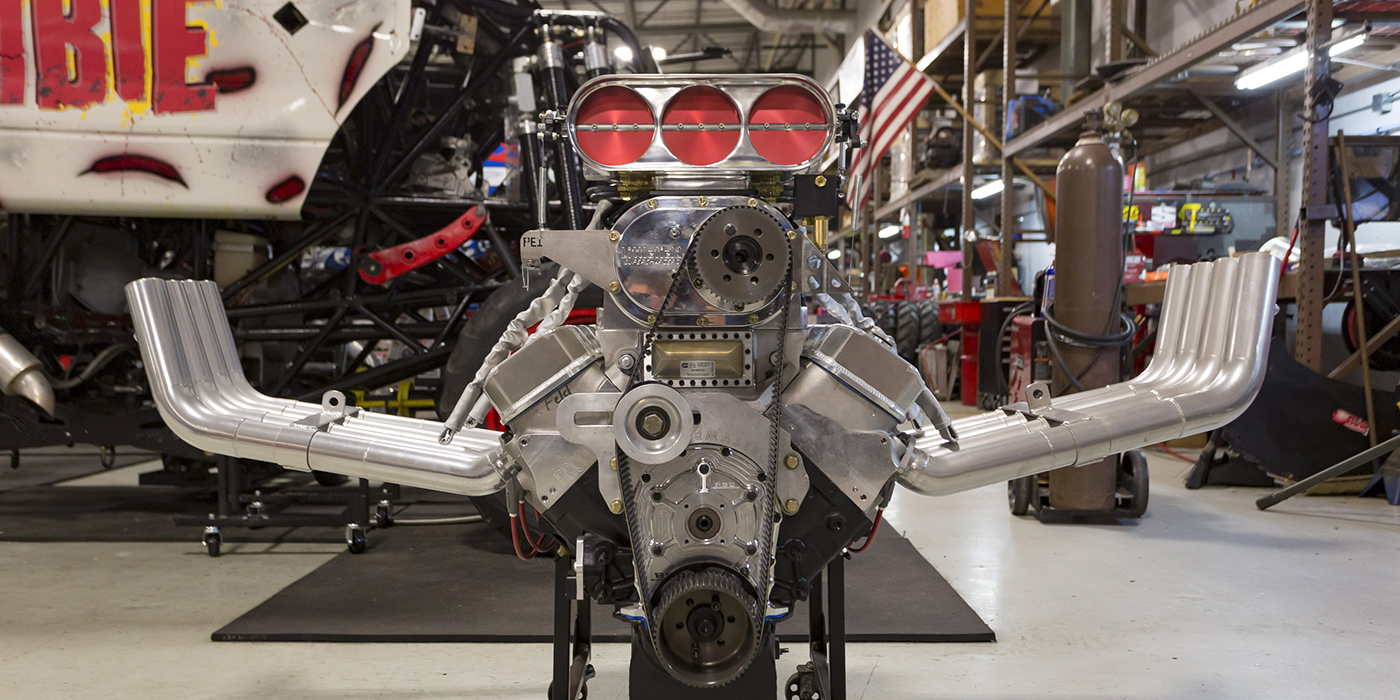

Monster Jam Logistics

Due to fans living all over the world, Monster Jam divides its shows into either a stadium show or an arena show, with the big difference being space.

Monster Truck Engines & the Laws of Physics

These 1,500 horsepower trucks break the laws of physics at every show by launching 12,000 lbs. 40 feet in the air and performing mind-blowingly outrageous stunts and acrobatics.

Harley-Davidson to Offer New Screamin’ Eagle 131 Crate Engine

The Screamin’ Eagle 131 is a bolt-in replacement for 2017-later model Harley-Davidson Touring motorcycles originally equipped with a Milwaukee-Eight oil-cooled or twin-cooled engine.

Holley Releases Assortment of New Products

A giant assortment of new products have been released from Holley, iNTECH, Sniper, and Brawler – high and low accessory-mount kits, two types of two-piece LS valve covers, cold-air intakes, dry-nitrous systems lower manifolds, retro-fit carbureted fuel modules, carb hats, and street/race carburetors.

408 cid Ford Windsor Stroker Engine

Looking to test real world differences between carburetor and EFI engine set-ups, while also testing different-sized camshafts, the team at Coast High Performance and Custom Performance Racing Engines built this 408 cid Ford Windsor Stroker engine. Read on to find out what went into the build and what the dyno results showed.

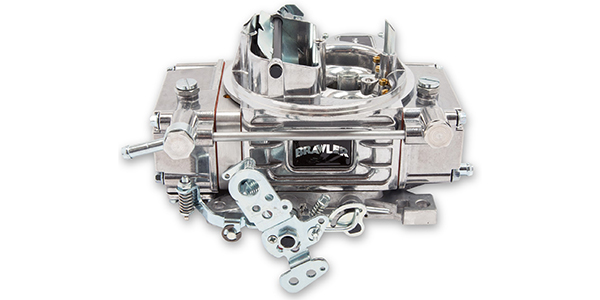

Brawler 600 CFM Side Hung Bowl Carburetors

Brawler has announced the release of 600 CFM Side Hung Bowl Carburetors, which feature a simple one-fuel-line connection and universal throttle levers to accommodate Ford automatic transmission kickdowns and GM 700-R4 mounting holes.

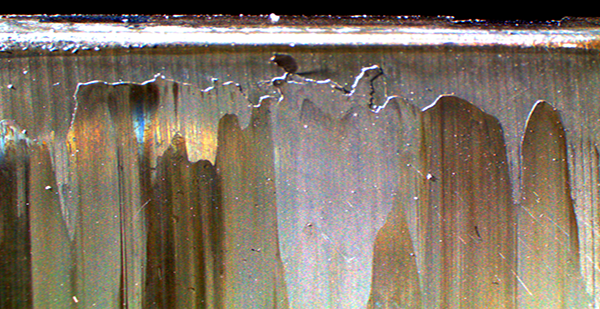

Analyzing Fatigue and Distress

Engine bearing inspection is a great way to get a visual indication of what is going on inside the engine under operating conditions. Upon teardown, the bearings will often have “tell-tale” signs of problems that have occurred and need to be addressed. However, the distress noticed in the bearing is often misunderstood and referred to

Holley Small Block Chevy EFI and Carbureted Intake Manifolds

Holley/MSD has announced the release of two new small block Chevy intake manifolds – one for EFI applications and one for carbureted engines.

The Anatomy of Carburetors

Carburetors are still a viable and valuable component for atomizing fuel. It is amazing that the carburetor has been around for well over 100 years. A small yet unique invention by the Holley brothers in the early 1900s provided the concept of what we use today. Holley became recognized in the high performance market when

Valve Failures Explained

Whether Thermal or Mechanical, Understanding Why Valves Fail Will Improve Your Skill Even engine builders with years of experience have valve failure at some point, but knowing what caused the failure is the difference between a builder who will learn from the mistake and figure out the solution versus one who will continue to make

All-Aluminum 535 cid Pontiac Engine

We all know this is an industry built on word-of-mouth reputation and recommendation, and no one knows that better than Bill Ceralli of Ceralli Competition Engines. He recently had a customer come to him on a recommendation from All Pontiac to build him this all-aluminum, 535 cid Pontiac engine for drag racing. Find out how this brand new build ended up churning out more than 1,000 hp!

Performance Oiling Systems

Regardless of what type of engine you are building, the oiling system must be capable of creating and maintaining adequate oil pressure and flow no matter what. Accelerating, cornering, hard braking or extreme RPMs should not cause even a momentary drop in oil pressure. It only takes a few seconds of oil starvation to spin

Piston Ring Selection

Through the proper selection of style, size and material, rings prevent blowby by sealing against the groove in the piston as well as against the cylinder wall. They should be as flat as possible, fit the piston grooves as tightly as possible, have the least amount of end gap that the engine can safely tolerate, and be as conformable as possible to seal against the cylinder wall.

Engine Math for Engine Builders

Engine building is a numbers game. Whether you like math or not, you often have to use it when figuring things like engine displacement, airflow, compression ratios and valve lift. Knowing how to calculate these values and how to use the numbers to match pistons, cylinder heads, cams, carburetors and valve train components can help

We Have Lift Off – Head lift and a look beyond the gasket

In the 1980s, many racers were experimenting with turbochargers on stock engines. Colossal horsepower and torque numbers could be produced for a short period until the engine self-destructed. One of the weakest links they focused on was how to keep the head attached to the block under extreme pressures. Many engine builders experimented with copper