As an engine builder who may not be comfortable with computers and electronics just yet, rest assured, what you know about engines, airflow and tuning won’t go by the wayside, but you’ll need to learn how to use a new tool. It would also help to be open to learning something new and be willing to take on a new challenge. Everyone has to start somewhere, but you’ll be miles ahead since you already know engines.

EFI systems control air and fuel through either a throttle body, port, or direct injection. EFI is commonly found on late-model stock engine applications. These systems have entirely saturated the OE passenger car and light truck market and are also installed on many performance and race engine builds. But EFI still holds a little bit of a stigma amongst some engine builders and enthusiasts who either prefer a carbureted engine or are intimidated by the digital aspect of the technology.

In years past, we’ve written many articles explaining the virtues of EFI, but today there’s no way to sugar coat it. Unless you’ve got a rock-solid niche business in building vintage engines, chances are you’ll need to become an expert with EFI products and how to tune engines with these systems. The good news is there are options for those who don’t like the digital side all that much.

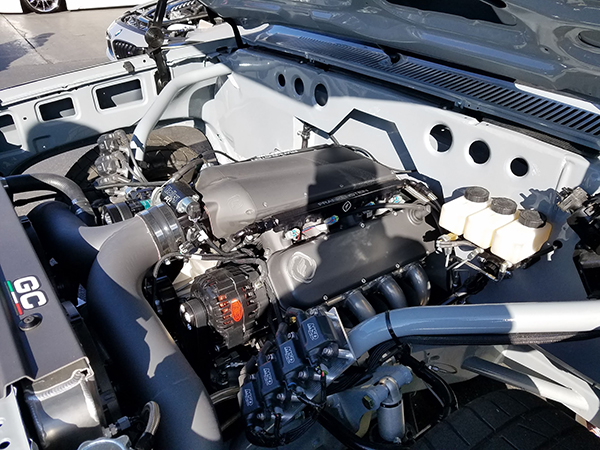

Richard Holdener recently wrote on Summit Racing’s, OnAllCylinders, how great it is to be able to grab a “used LS (as well as a Gen III Hemi or Coyote), high mileage at that, add a cam, springs and boost, and make four-digit power.”

Holdener said much of the credit goes to the development of modern fuel injection along with affordable power adders. He is correct in this assessment. What makes 1,000 horsepower applications so accessible today comes down to the flexibility and control that a quality EFI system provides. While many other components make-up these “horsepower monsters,” none of it would be possible to tame for the street and get good fuel mileage to boot without EFI.

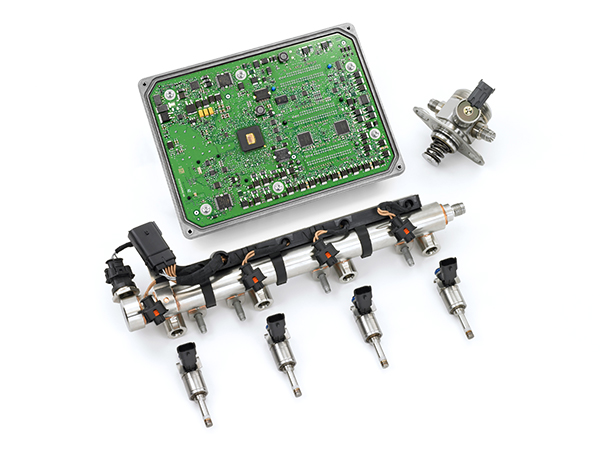

EFI can be operated in an open-loop or closed-loop setting. In open-loop, EFI does not compensate for changes in air density. Reprogramming the ECU is needed to tune for weather or altitude. In closed-loop, EFI automatically regulates the air/fuel ratio with a wide-band O2 sensor to measure for air density changes. EFI is a complicated setup that includes several components such as a throttle control, sensors, a fuel pump, a regulated fuel return circuit, electronic injectors, a controller, and programmer. Electronic injectors in higher power applications require high current power supplies over the low current OEM power supplies. In some high horsepower applications, fuel pressures need to be regulated from low volume, idle mode to high volume, full power mode.

For your “old-school” engine builders, EFI can be intimidating, dealing with all the above, but some are beginning to embrace the technology as a way to grow business. However, many are still reluctant to learn about it.

“I’ve seen some embrace the technology and show a desire to learn how to use the ‘tool’ known as EFI,” says David Page, technical director of training, Comp Performance Group. “While others are 100% resistant to learning about it. I’ve found that age is not necessarily a factor in the willingness to embrace this (and other) technology.”

With EFI, there doesn’t seem to be many people in the middle, according to Page. “I have had the pleasure of teaching some very seasoned engine builders about EFI, and it is awesome to see their knowledge of engines, airflow, fuel demands, etc., put to use as they learn to use this powerful tool. I have learned as much in these situations as I taught. It has been a pretty cool synergistic experience for me.”

Page believes the biggest obstacle is the need to be open to learning something new. “Every car enthusiast was completely ignorant about engines and cars at some point, but we all learned, driven by curiosity, passion, or necessity.”

Some are intimidated because of the electronic component, but as with all things, Page says this can be broken down into small processes and concepts. “Once you get to that point, it’s no more challenging than any other system or component.”

Page says that the trend toward EFI has begun in earnest with the development of a sub-market of automotive Electronic Fuel Injection that caters to entry-level users. “Technology that uses the Wideband O2 sensor to allow the system to ‘learn’ the fuel needs of the engine have made these systems easier to use in the proper applications.”

But for engine builders who are more experienced with EFI, using a system that offers a broader array of features allows more flexibility (but at a higher cost, too). These systems provide more inputs for reading auxiliary sensors, more advanced data-logging and more advanced vehicle management features, according to Page.

Over the past few years, a lot more direct injection engines have hit the market, and variable cam timing has become the standard for stock passenger car/light-duty truck applications. While on the performance side, there’s more electronic integration to control the entire vehicle. Data acquisition systems are linking to engine management systems and powertrain control systems. With the variety of electronic controls on a modern engine, systems have to start talking and working together.

Tuning an EFI system does require the tuner, whether that’s an engine builder or someone else more tech-savvy, that truly understands engines. Our EFI experts say that being a tech-savvy guru may help in some areas, but the best tuners understand engines and they can operate a laptop. And by now, you should know how to use Windows at least. Most of the software is not difficult to run; the challenge is understanding the inputs and how they may affect the engine’s performance.

The myth that carburetors make more fuel is not exactly a fact, according to Page. “From a technical perspective, there is little hard evidence to support the claim that a carb atomizes the fuel better than a fuel injector to add to which fuel atomization is not the only factor in fuel efficiency. With an EFI system, we are a little more flexible in the shape and location of fuel distribution and spray patterns; this is something that carbs don’t offer. New fuel injection technologies are allowing higher fuel pressures, and interchangeable injector nozzles are proving to be an interesting area of development for tuners.”

Page says EFI product offerings have continued to broaden as the market demands increase. “Our customers like being able to buy everything they need from one source. We offer kits in various configurations, and also offer a wide variety of components for more custom applications. Intake manifolds, throttle bodies in various configurations, injectors, fuel systems, ECUs, wiring harnesses, various sensors, and a full line of ignition components allow us to meet most any engine management needs. When the convenience of installation is most important, customers lean toward throttle body type systems. Other customers prefer multiport-style systems. We can accommodate both.”

Whether you can make more power with EFI than with a carburetor is a question for the ages, Page acknowledges. “The first question that you must address is how does the engine know if it has a carburetor or EFI? I believe that there are potential power advantages of EFI systems, mostly related to the level of control you have over the delivery of the fuel. One challenge in giving EFI a fair fight is that back to back tests are usually performed using the same manifold that is optimized for use with a carburetor.

A carburetor does have some inherent advantages to its design as it atomizes the fuel well, which is more difficult for injectors, especially direct injection. Atomization has a cooling effect as the air/fuel mixture passes through the manifold. Still, Page says it can be duplicated in an EFI application by using the properly designed and sized injectors. “I believe given the freedom to design an induction system that is optimized for EFI use, EFI can make more power than a carburetor!”

EFI systems are available in a variety of packages, and tuning can be as simple as running a “learn” mode. But most engine builders and tuners will use either an engine dyno or chassis dyno to fine-tune their maps. But some systems include a set of base maps to get you started.

“Our systems come with a library of tunes named by engine displacement, injector size and naturally aspirated or boosted,” Page notes. “These serve as good starting points for most applications, and our technical support team can assist with some of the less common scenarios. All of our systems feature our Adaptive Learn technology, which uses the feedback from the closed-loop O2 function to build a fuel map for a particular engine. Depending on the application, this can be used exclusively, or it can be used to tune areas of the map that the tuner cannot or does not have an opportunity to get to during the tuning process, or can be turned off completely if the tuner wishes.”

Chassis and engine dynos offer the opportunity to perform the most detailed calibration of any system, according to Page. However, FAST’s Adaptive Learn feature allows the calibration process to continue automatically as the vehicle is driven, which he says is especially useful in the light throttle or “cruise” areas of the fuel map.

“In my experience, the engine builders who embraced EFI 5-7 years ago have advanced their knowledge, and in doing so, have set themselves apart from others in their field,” Page explains. “This makes business sense as it is just like adding a new machine to your shop. More opportunity to add value to your work for your customers. This allows an engine builder to increase profits and also deliver a true ready to run package to their customers.”

EFI systems from a few years ago have evolved by adding more advanced features and can communicate with other vehicle systems. Additionally, the systems today are generally less expensive. A fully programmable unit may only run $1,500-$2,000 compared to two to three times that five years ago.

The trend, in our opinion, is there will be more options and features for less money, which is not a bad deal. Of course, you’ll need to invest in your training, but that’s always a good idea, and a topic for another issue. EB