Mash the Throttle: Monster Trucks Engines & How They’re Breaking the Laws of Physics

It used to just be loud engines and big tires. That’s what you’d get if you attended a monster truck show 30 years ago or so. Sure, they’d also jump and crush cars as part of the racing, but today that’s all changed. A monster truck show still delivers loud engines and big tires, but today, these 1,500 horsepower trucks break the laws of physics at every show by launching 12,000 lbs. 40 feet in the air and performing mind-blowingly outrageous stunts and acrobatics.

Don’t get me wrong. What was being done with these trucks 30 years ago was certainly unique and impressive for the time, but today’s Monster Jam events, put on by Feld Entertainment, Inc., are nothing short of a spectacle. In order to put on a show of this caliber and magnitude, the folks at Feld Entertainment and their partners need to have every aspect buttoned up tight, even when things go wrong.

We caught up with Jared Alderson, who has a background working with Dennis Anderson of Grave Digger fame and Feld Entertainment in the engine room under the tutelage of Richard Midgette, to keep these 1,400 horsepower, big block Chevy, blown alcohol engines performing at their best.

“I was working with Dennis Anderson at his mud bog prior to working with Feld formally,” says Alderson. “About four years ago, they had an opening in the engine room, so I was able to start working here as an engine builder partially through a recommendation from Dennis. I had known of Richard Midgette, who has run the engine program at Feld for many years. It was an honor to meet him and an honor to work under him and I certainly learned a lot during my time there.”

Some of what Jared learned was that Feld Entertainment is an expert at putting on these large traveling shows. In fact, the Palmetto, FL-based company owns not just Monster Jam, but Disney on Ice, Monster Energy Supercross, Disney Live!, Marvel Universe Live!, Sesame Street Live!, Trolls The Experience, and Jurassic World Live Tour.

When it comes to Monster Jam in particular, Feld owns more than 50 monster trucks and a fleet of more than 100 blower engines. There are also plenty of duplicate trucks in circulation in order to logistically have all those trucks at different events. Monster Jam does more than 70 shows from January through the end of May, culminating in the World Finals.

“There’s eight or nine active touring Grave Diggers,” Alderson says. “There’s four or five different touring Max D trucks. There’s four or five El Toro Loco trucks. In a given weekend, they’ll have a show in maybe Minneapolis, Houston and Dubai.”

We found out there’s a ton of effort put into these Monster Jam shows and into the trucks that keep thousands of fans entertained at each venue.

“At the headquarters in Florida, Feld has floors of people whose job it is to do nothing but book hotel rooms, flights, schedule venues, deal with logistics, etc.,” Alderson says. “Feld is pretty good at putting on a show and engaging the crowd. They’ve got that down to an art. It has certainly come a long way from the mud bog.”

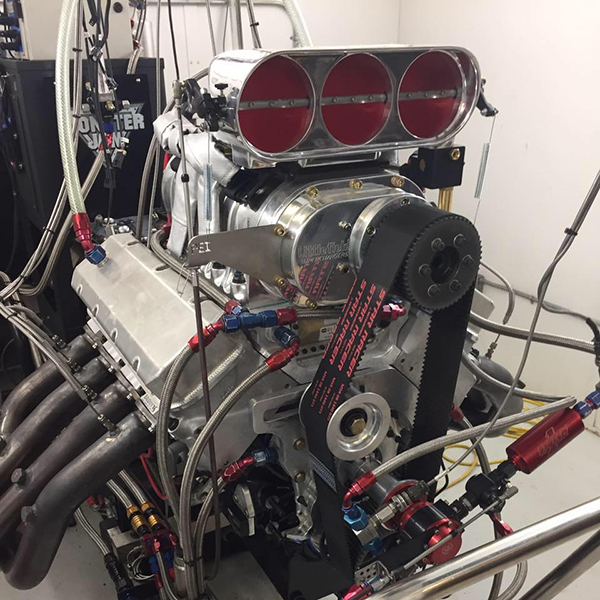

Monster Trucks Engines and Components

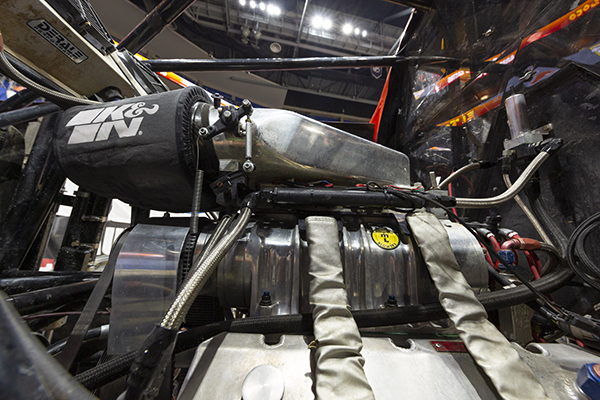

Nothing is more evident of that evolution than the changes in the 540 cid big block Chevy blown alcohol engines inside each truck. Each Monster Jam truck is approximately 10.5 feet tall, 12.5 feet wide, 17 feet long and weighs 12,000 lbs. A monster truck engine can generate up to 1,500 horsepower, thanks to a blower that forces air and fuel into the engine. It is powered by methanol fuel, consumed at the rates of three gallons a minute from a specially constructed safety cell.

The truck utilizes a four-link racing suspension with four main bars that link the front and rear axles to the frame. It rides on clusters of nitrogen charged shocks that offer 30˝ of travel in the suspension. The BKT tires are 66˝ in diameter and 43˝ wide, inflated to 16-20 psi and weigh 645 lbs. each (with wheel).

The driver’s compartment is a steel safety structure, built from tubing and mounted to the truck frame. The truck bodies are custom-built and constructed of fiberglass. Each truck is transported in specially prepared trailers, which can include spare parts and as many as two trucks.

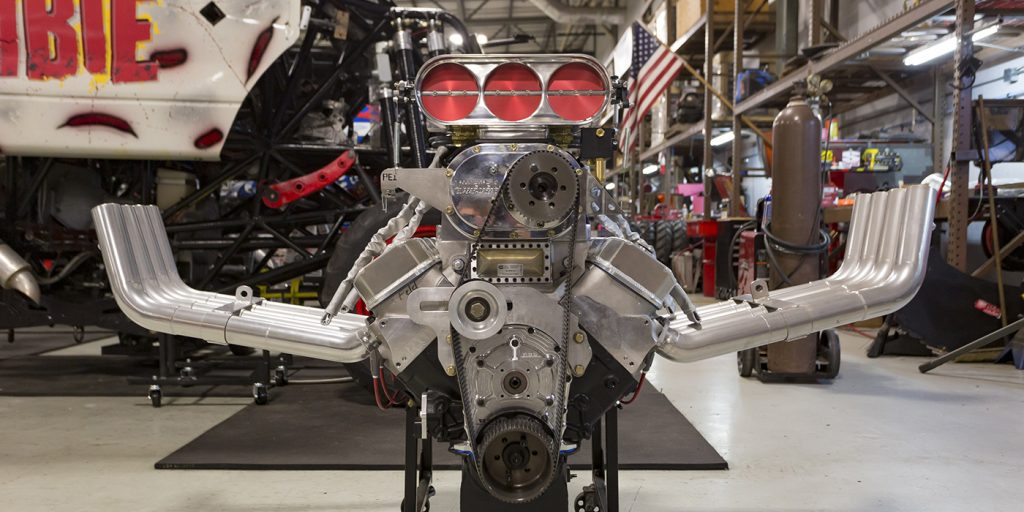

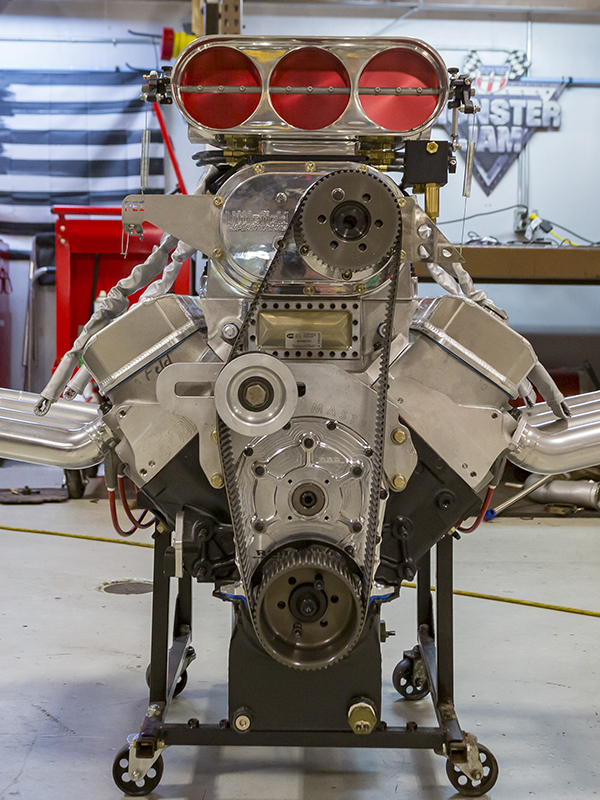

The starting point for assembling each monster truck’s 540 cid big block Chevy blown alcohol engine is a World Products block.

“Monster Jam, and Dennis in particular, has had a very long-standing relationship with Paula and everybody at PBM and World Products,” Alderson says. “World Products’ blocks are really, really usable. They hold up really well. A lot of people think these engines get torn down every weekend and freshened up. That’s really not the case. Usually they’ll go 20 to 25 hours inbetween freshman ups, and when they do, the blocks clean up. If it was a 4.500˝ bore, usually they’ll clean up at 4.510˝ or 4.530˝. We get years and years out of the blocks, until a rod goes through the side of it, which usually means an Anderson or a Meents was driving.”

When it comes to the components used in these monster truck engines, there are certain parts that may live forever in a drag car, trophy truck or circle track application, but fatigue in a monster truck. For that reason, Richard Midgette has been leading the charge when it comes to working with the various manufacturers on parts.

Some of the parts found in monster truck engines are Brodix cylinder heads, Pac springs, Ferrea valves, Crower lifters and rockers, Crower or Callies crankshafts, ARP hardware, King bearings, and COMP Cams camshafts.

“COMP Cams has come up with a grind that produces more average horsepower than what we were using,” Alderson says. “As technology changes, cam technology always evolves and COMP was able to deliver drivability and response. Those are some of the changes that we’ve been able to make in large part due to Richard working with the manufacturers on improving parts over the years.”

Monster trucks also feature an 8-71 blower from either The Blower Shop or Littlefield Blowers, and they’re limited to 10% over on the overdrive. They still use a magneto and a mag box, but according to Alderson, there’s been talk of possibly going coil on plug.

Other parts include a Littlefield intake, Enderle injector hat, Magnaflow headers, Moroso oil pan and valve covers, Bill Miller (BME) aluminum rods, Diamond pistons, and Total Seal piston rings. The engines also run a wet sump oil system with a Melling oil pump and Lucas Oil 50-weight oil.

“Due to the wet sump system, when they stand the trucks on the nose or do donuts, we have oil delivery issues because those are unique fluid delivery needs you don’t really see a lot of other places,” Alderson says. “Moroso makes a specific pan that’s been through multiple iterations with the baffles, trap doors and pickup location.

“One of the hard parts about it is the trucks land so hard, the g-forces can break parts like the oil pump off the motor. That’s not a knock on Melling, it’s just a unique problem you don’t see in something like NASCAR.”

Monster trucks also use a Waterman mechanical fuel pump, and because the fuel sloshes so much in the tank, a metal tank cannot be used. Instead, a poly tank is used because the impact and g-forces of the truck landing can burst a metal tank.

“There are certain limitations to what we can use,” he says. “The fuel delivery and the suction from the tank to the pump is a pretty serious issue. There’s a lot of tools Holley EFI gives us in terms of fuel pressure compensation by holding the injectors open longer when fuel pressure drops and/or different tuning tables that you can use to try and help get the engine started when there’s no fuel pressure. Ultimately, you can’t beat physics. If the truck is on its nose for a minute or two, the fuel pickup is out of the fuel, so it makes it really hard.”

With each successful trick, the challenge is raised to go faster, higher or farther than before.

To remedy that issue, Monster Jam has introduced Holley’s HydraMat, which basically acts like a diaper in the fuel cell and wicks fuel to the pickup even when the pickup is out of the fuel.

“We actually tested it on the dyno and rocked a fuel cell back and forth and measured, and there was zero drop in fuel pressure,” Alderson says.

However, engineers found that when the monster trucks went upside down, the HydraMat had a tendency to fold into itself. A fix for that problem was made and the HydraMat has been very successful at alleviating fuel delivery pains.

Another big contribution to these monster truck engines has been the Holley EFI system. Up until recently, monster trucks used mechanical fuel injection, which was very good when trucks were flat on the floor. Where it wasn’t so good was at idle or low engine speeds.

Making the switch to EFI allowed the trucks to use roughly half the fuel as with mechanical fuel injection, improved emissions, kept a similar air/fuel ratio, and lower in the rpm range EFI is a lot leaner, which made it cleaner, more efficient and better on the engines overall.

“One of the interesting things we found going to EFI was it actually increased the engine life, which isn’t terribly surprising having a better and more consistent air/fuel curve than the mechanical stuff,” Alderson says. “It definitely helped the engine life and prolonged cylinder wall life.

Of course, when assembling one of these big block Chevys, everything is measured like any engine builder would – bearing clearances, ring gap, piston rock – all that stuff is checked and measured. Everything is balanced every time and the cranks and heads are all checked for cracks every time.

“If something bad happens, the potential for a disaster is immense,” he says. “Having a component that’s been safety tested and rated takes some of the liability out of the equation. If you’re going to go racing in front of people and something happens, it’s probably wise to have SFI-rated components and that’s something Feld doesn’t mess around with it all. If it’s not safe and proven to be so, then they don’t want anything to do with it.”

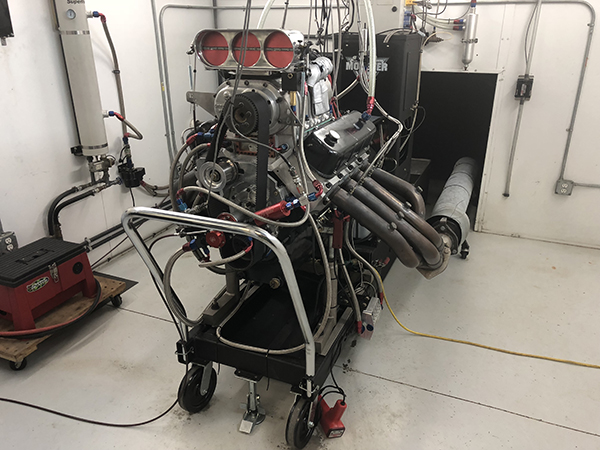

While monster truck engines can churn out 1,400 horsepower, they do so by prioritizing reliability so the trucks are able to remain out on the floor for entertainment.

“They don’t tune every engine off the dyno for every last bit of horsepower,” he says. “Horsepower can be a bit of a dirty word because they’re very concerned in a fleet of trucks about longevity and making the show. If it was going to have a 200 or 300 horsepower increase, but it meant the trucks missed 10% or 20% of the shows because reliability goes away, that’s where they stand on that balancing aspect. They want as much power as they can get, as long as they can make the show every single time.”

Prioritizing reliability means they don’t run so much as a new pushrod, a new rocker or a new cam in front of fans without doing some pretty serious field testing first.

“Feld does a lot of testing and spends a lot of money testing,” he says. “They’ll test new ramp designs, new camshafts, new fuel injection set ups or whatever it might be. They’ll do weeks-worth of testing before it ends up on the floor in front of 70,000 people.”

Common Issues

Richard Midgette would often say, ‘If you ever want to test a product, we’ll bolt it to a monster truck.’ What holds up in other forms of racing for years and years, has a much more limited life span in a monster truck. This is due to the throttle input of the drivers, the impact of the trucks landing and the fluid delivery for both fuel and oil.

“We get asked all the time, why don’t we just go to a dry sump,” Alderson says. “Well, when the truck rolls over and you’ve got five gallons of 250-degree oil right by the driver’s head, there’s some pros and cons and some risk there. By and large, the wet sump is a little less complicated to deal with.

“Fluid delivery has hands down been the number one problem both for the engine and the transmission. There’s been a lot of innovation from that and a lot of new things that were tried. Some worked, some didn’t work, but it always continues to evolve.”

Case in point, years and years ago, all the engine used to be in the front of the trucks. However, when you did a wheelie across the floor, the oil pump pickup was out of the oil and you starved the engine for oil.

“For weight balance reasons and for the idea that the truck is going to do a wheelie across the floor on the back wheels, the oil pump pickup is in the front of the engine and the engine is in the truck backwards,” Alderson says. “They run a drop-style transfer case, and obviously, the truck goes forward when you put it in drive, but the engine and transmission are in there backwards on most of the trucks. However, now that they’re doing tricks on the front wheels too, the oil pump pickup is out of the oil again. We’ve talked about v-shaped oil pans, and ultimately, it may end up going to dry sump.”

While the fluid delivery issues are some of the most common things seen, there are some parts such as pistons and rods that are usual suspects for damage. However, despite the harsh operating conditions of monster trucks, three quarters of them come back after one to two years ready for a freshen up.

When things do go wrong during a show, Monster Jam’s crew is at the ready, and they’re prepared for just about any situation.

“If somebody loses a transmission in round two of racing it has happened before where they’ve had it back out on the floor for round three of racing 15 minutes later,” he says. “It’s a pretty amazing feat to watch. They have what they call the crash box, which is a toolbox with all of the emergency tools. They’ll pull the damaged truck to the crash area and there’s a team of guys waiting. If it slung a driveshaft out of it or has a broken axle shaft or whatever the issue is, they’ll tend to it, quickly.”

The part that a lot of people don’t get to see is the crew guys. Inbetween rounds or inbetween shows, the crew guys have the toughest job out there.

“They’re working on a dirty, nasty, muddy truck with oil running out of it,” he says. “Everything is hot to touch and hot to work on and somebody is screaming at them that the truck has to be back on the floor in five minutes, but they get that work done.”

Of course, all of this – the show prep, the truck and engine development, the training of hundreds of crew members – is all worth it when Monster Jam fans are entertained and in awe of what they’re witnessing out of these incredible monster trucks and the drivers behind the wheel. EB