REBUILDING THE 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would

Reusing, Reclaiming, Remanufacturing – Whatever you call it, it’s how the industry recycles parts and components

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy. You’ll reuse, reclaim or remanufacture it for your specific job. Whatever the reason may

Blast Off – What’s New in Blast Media and Machines

In this industry, it’s often cheaper to remanufacture or rebuild an engine than it is to make a new one. However, doing so requires cleaning worn and dirty parts. In addition, customers these days are increasingly asking for cleaner parts and engines. How are you supposed to get tough grease, oil, rust, paint, carbon build-up,

Turbochargers: Boost Your Turbo IQ

In the past decade, turbochargers have found their way onto more engines in cars and light trucks than ever before. By 2021, predictions by some experts cite turbocharged vehicles will reach up to 38 percent of all new vehicles sold in the U.S. Once thought of as only a means to increase performance on exotic

Valves & Seats

When it comes to engine components working together, there are few areas that share the same level of relationship as the valves and valve seats. The factors that affect this duo’s ability to reside in harmony inside an internal combustion engine encompass everything from material compatibility to thermal conductivity. In regard to the actual physical

Reusing, Reclaiming, Remanufacturing

No matter what kind of engine builder or remanufacturer you may be or what applications you build for, at some point in time you’re going to run into a situation where a used engine part or component will come in handy.

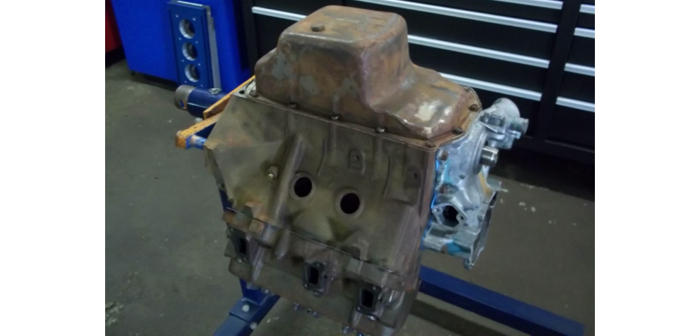

Rebuilding the 5.7L HEMI

Back in the early ’90s, when Chrysler realized that it would need a new truck motor to replace its 318/360 Magnum engines to meet the coming emissions standards, the company considered two pushrod engines along with one SOHC design and concluded that a pushrod motor with a pair of Hemi heads that really breathed would make a great truck engine and could still be used in its cars. This is how the 5.7L Gen III Hemi was born in 2003.

JET Tools Industrial Grade 60 and 80-Gallon Oil-Lubricated Air Compressors

The vertical-style compressors feature cast iron pumps, ASME-certified tanks and durable and industrial-rated NEMA motors for dependable, long-lasting service. Each compressor has a built-in safety valve, high pressure switch and a fully enclosed metal belt guard to help ensure safe operation.

How to Find and Fix Cracks

Cracks are bad news because they never heal themselves. Once a crack starts, it always gets worse. Checking critical engine parts and castings is time well spent if it heads off a major problem that might result in a major engine issue or a warranty claim.

The Daily Grind

Today, seats are made of a wide variety of materials, different combinations of various alloys, powdered metals and other super hard materials. This seat material is designed to prolong the ability of the valve seat to seal against the pounding of the valve head during engine operation. The variety of materials also means new and different abrasives are required for proper machining.

Spick-and-Span

As engine technology continues to evolve, so have the cleaning processes for removing dirt, grease, oil, hard carbon deposits, rust, scale, corrosion and discoloration from engine castings and components. Several factors make cleaning more challenging today.

Shop Solutions December 2015

Despite what you may believe, there is a way to recondition the so-called “cracked” rods, or powdered metal connecting rods. I use a media made of coal slag that can be found at most home improvement stores.

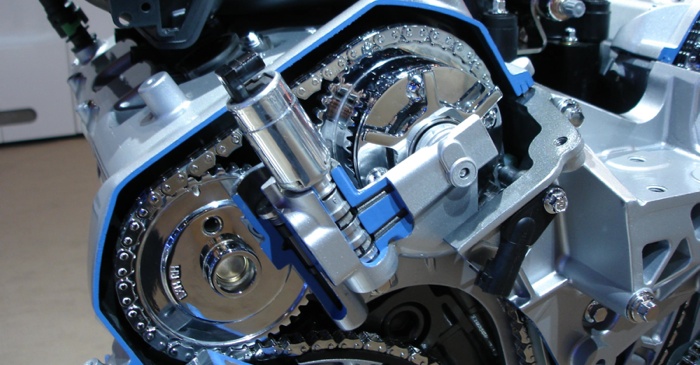

Timing Components

For metal parts to rotate, move, lift, bend, sway and – hopefully – not touch multiple times per second, every minute of every hour the engine is running takes more than just good enough – it takes precision that Swiss railroad conductors would envy. While everything in the engine has to precisely fit and accuracy is key, nowhere is precision more critical than in the timing.

Engine Block and Head Repair

A cracked cylinder head or engine block may or may not be bad news depending on the size and location of the crack(s), the value of the casting and what it will take to fix the crack(s) versus what it would cost you to replace the casting. Read what your options are in this Larry Carley feature.

The Ford ‘FE’ – Rebuilding An American Iron Icon

Ford produced the FE series engines for almost 20 years and in this time period, this series of engine gained quite a following. After researching the FE, I was intrigued about its internal workings. I had always heard about and seen some of the more popular FE engines such as the 390, 427 and 428 but never had a chance to dive into one – until now.

Kaase Introduces Boss Nine Engine Kits for Common Ford 429-460 Big Blocks

For engine builders, and enthusiasts with ambitions in hot rod engine assembly, Jon Kaase has introduced the Boss Nine in a new kit form. Among the kit’s more prominent components, Kaase includes his noted semi-hemi cylinder heads with accompanying pistons, pins and rings as well as pushrods, shaft-mounted rockers and induction system. Everything to complete

Handling Stress Fractures

Salvaging Cracked or Flawed Engine Parts through Detection and Repairs Cracks are often blamed as the cause of a head failure. In many instances, the cracks are not the cause of the failure, but a symptom of another underlying problem such as overheating, detonation or incorrect installation (wrong torque on head bolts, dirty bolt threads,

Scratching the Surface: Coatings and Treatments for Engine Components

When it comes to preserving performance parts, it’s the ‘Icing on the Cake’ Various kinds of coatings and surface treatments can be applied to engine parts like icing on the cake to improve durability, enhance scuff resistance and lubrication, control heat, boost thermal efficiency and reduce friction. No single coating or surface treatment can

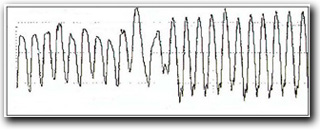

Surface Finish Testing: Dealing with Dirty Patches

Gauge calibration is a routine process followed by most users of precision gauges. How regular a gauge needs to be checked and its performance documented is usually defined step-by-step in a documentation procedure. Surface finish roughness instruments use a roughness specimen, or “patch,” that is certified for a known wave form to provide a specific

Surface Finish Testing: Dealing with Dirty Patches

Surface finish roughness instruments use a roughness specimen, or "patch," that is certified for a known wave form to provide a specific surface parameter result. With this certified specimen in hand, it is easy to verify that the surface finish measuring instrument is reading properly. Because of the nature of their sensitive probes, and because