PERA’s Core Corner

During our research of the General Motors Gen III engine family we continued to run up against a stumbling block of exterior identification between the 4.8L and 5.3L engines. It seemed that no matter who we spoke with, be it core suppliers, wrecking yards, engineers or rebuilders, when asked how they differentiated between the 4.8L

Valve Guide Reconditioning

A valve loses about 15 to 30 percent of its heat through the stem. On the exhaust side where there is no cooling effect from the incoming air/fuel mixture, the guides are critical, because cooling through the stem is especially important for valve longevity. Worn intake guides or ones with too much clearance can also

Align Yourself

The crankshaft main bores are the foundation of every engine block. The alignment of the main bores is important because their position establishes the centerline of the crankshaft and how the crank aligns with the cylinders, deck surfaces and camshaft. Misalignment in the main bores can cause binding and premature main bearing wear. Misalignment occurs

Valve Seat Installation Procedures

If a valve seat is damaged, cracked, loose, receded or too badly worn to be recut or reground, it can cause a variety of problems: loss of compression, valve burning, valve failure, valvetrain wear and breakage, even head and valve damage if the seat comes loose. For that reason, replacing valve seats is often necessary

The Smooth Science of Cylinder Honing

The basics of honing cylinder blocks hasn’t changed much in recent years, but what has changed are the type of abrasives being used by many engine builders. Silicon carbide and aluminum oxide honing stones of various grits have long been used in power honing machines and portable hones to finish cylinder bores. These types

Valvetrains: Better Materials & Design

Pushrods would seem to be an endangered species these days, atleast as far as most new engine designs are concerned. The onlybrand new engines built in recent years with a pushrod valvetrainhave been Chrysler’s 8.0L V10 for the Viper and Dodge Ram, andGeneral Motors new "LS1" 5.7L small block V8. All therest have either been

Ensuring Bearing Life: Crankshaft Bearings Are Always Replaced When Rebuilding An Engine

Crankshaft bearings are always replaced when rebuilding an engine because they’re a wear component. Heat, pressure, chemical attack, abrasion and loss of lubrication can all contribute to deterioration of the bearings. Consequently, when an engine is rebuilt new bearings are always installed. “Reading” the old bearings can reveal a great deal about conditions that may

Getting A “Good Seat” : The Growth In The Valve Seat Insert Market

The growth in the valve seat insert market can be traced back to the early 1970s when the switch to unleaded fuel took place. Most of the engines in use or that were in core or inventory storage had to have replacement seats inserted in the exhaust side to prevent valve seat recession that occurred when the engines were run

Valve Guide Repair Options

One thing you can almost always count on when rebuilding a cylinder head is worn valve guides. The guides experience a lot of wear because of the constant friction between the guide and stem. To make matters worse, positive valve seals on late model engines prevent the guides from receiving much lubrication. Side forces on

Melling Chromoly Oil Pump Steel Gerotors for Ford 5.0L DOHC

These chromoly steel gerotors offer increased tensile strength and toughness. Recommended for race and power-added applications.

Turbocharged 6.7L Second Gen Cummins Engine

Thanks to attending a truck pull event at an early age, Sean Purdy can’t shake his passion for diesel trucks and engines. He recently completed a fresh build on his 1999 Ram 2500 with a turbocharged 6.7L Cummins second gen-swapped engine.

The Engine Cummins Never Built: A Look at the 6.4L Cummins

With increased technology in turbo systems as well as fuel systems, the final limits of the 6.4L Cummins have not yet been discovered. These engines are capable of being a competitor in any event, whether it be truck pulling, drag racing, or cruising the strip.

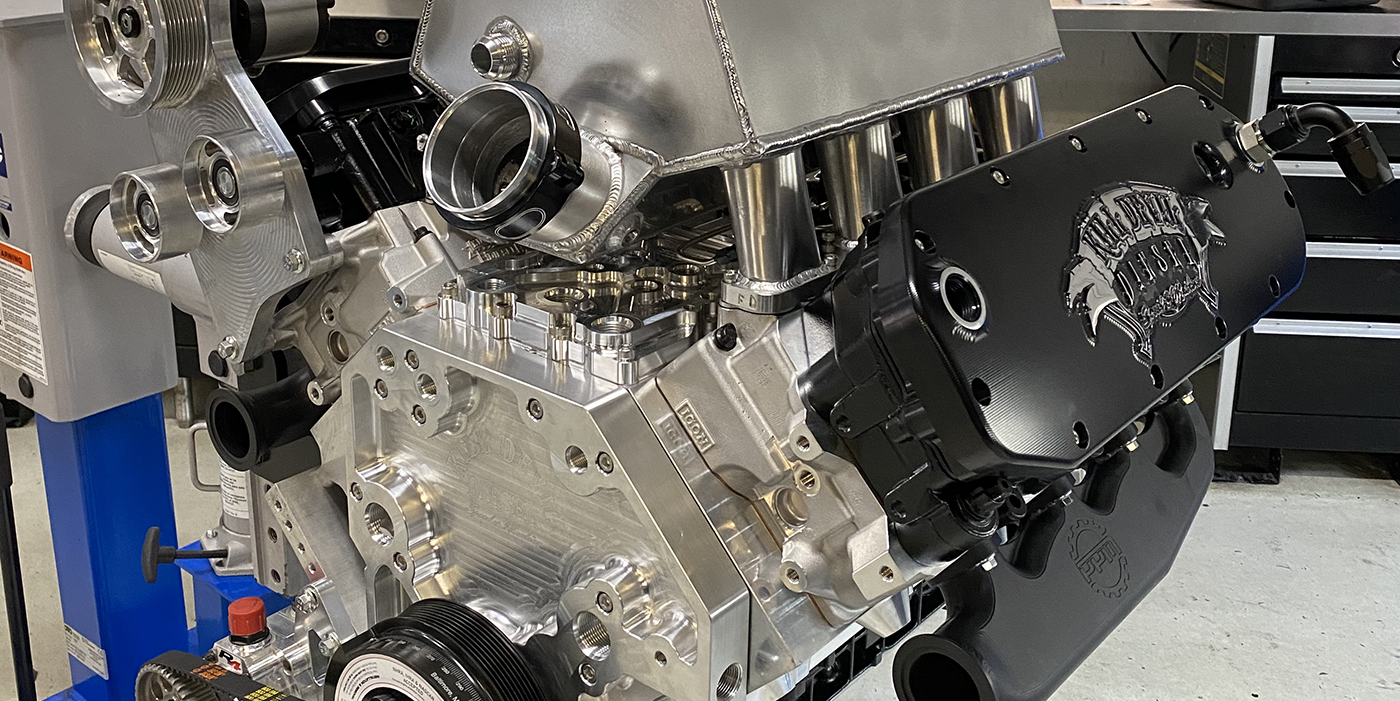

Billet 6.0L Powerstroke Engine

Leave it to Jared Alderson and the guys at Kill Devil Diesel to build a kickass Powerstroke engine! This competition-level, billet aluminum 6.0L will be going under the hood of KC Turbo’s truck for the upcoming race season. Check it out!

12-Valve 6BT Cummins Engine

Eric Lucy and his 16-year-old son have been hard at work over the past two years building a 12-valve Cummins to drop into his F-250 King Ranch. Check it out!

All Things Media Blasting

Engine building is a segment of the automotive industry that has always been ahead of the curve in media blasting, and no matter the engine shop, cleaning equipment is a common bond.

Building a 6.0L LS Engine

What’s more legendary than the LS engine? With over 20 years in production, the LS has become the chosen V8 for many an engine builder. This article dives into what you’ll need consider when building a high-performance 6.0L LS engine.

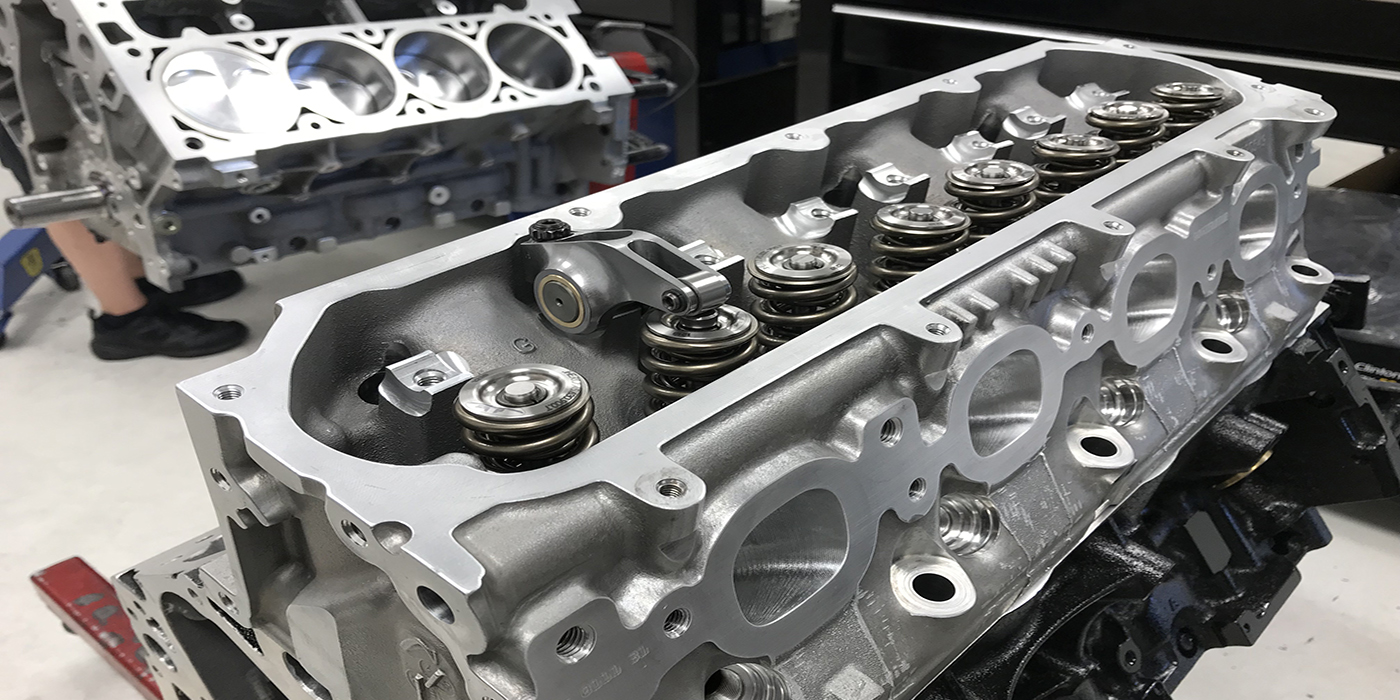

LS Valvetrains: Take Something Good and Make it Better

I’m not sure anyone ever complained about the performance of a Gen III or Gen IV small block Chevy as they came from the factory. Let’s face it, they run good and some of them are downright wicked. But, thanks to engine builders and aftermarket performance parts, there’s always a way to make them run

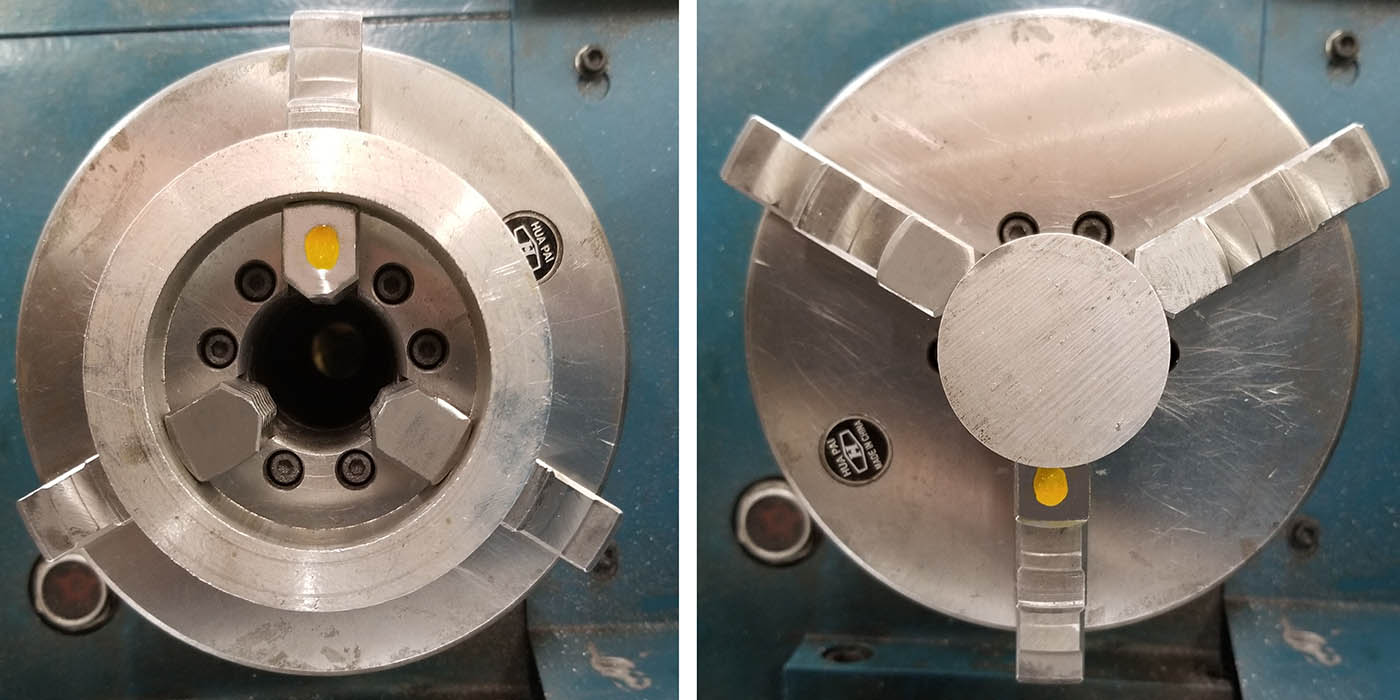

Shop Solutions January 2022

Check out these Shop Solutions from builders across the country!

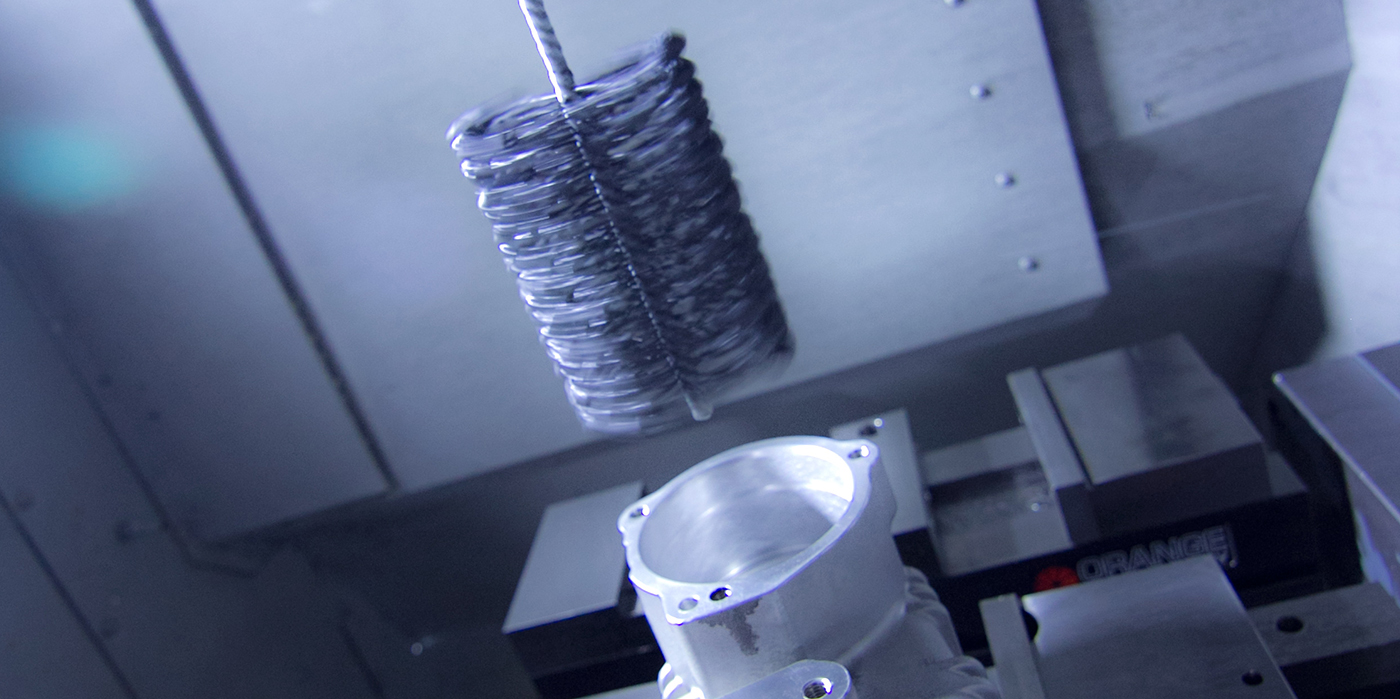

Debunking CNC Abrasive Finishing Tool Concerns

Machine shops are increasingly turning to abrasive finishing tools that can be easily integrated into CNC machine carousels or tool holding systems.

Motorcycle Valve Seats

As it related to valve seats, it is important to know a bit about the different materials used and when and where it is appropriate to use them.