Few engines can lay claim to popularity levels quite like the LS engine has seen over the years. You’ve all built or rebuilt them, customers want them and there’s plenty of good reasons for that. They are simple, compact and respond well to modifications. In addition, they are reliable, their stock bottom ends can handle a lot of power and they can be, and have been, installed in virtually any car you can imagine!

A strong argument for the LS is the fact the platform has been around in one iteration or another for 25 years. While the LS still seems like cutting-edge technology, it has been up and down and around the track a few times. That history means there is a large knowledge base to tap into on LS engines from manufacturers and engine builders alike.

While in recent years, there has become a finite amount of LS engines out there due to people rebuilding them at the rate they are, the aftermarket support has been stellar for these engines, and it’ll likely continue for decades to come. As such, here’s a look into ways to get the most out of a 6.0L LS build.

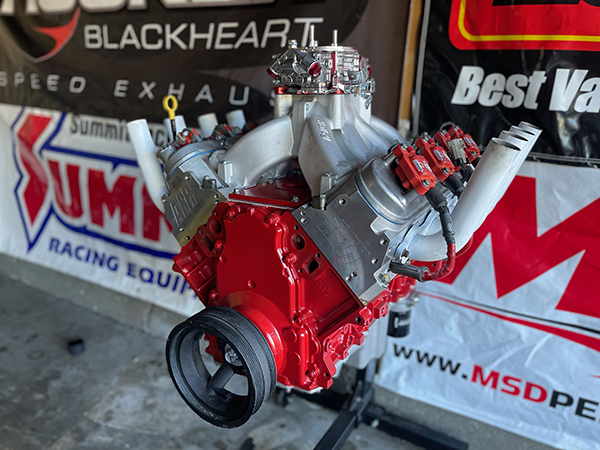

This 400 cid LS features twin 76mm Precision turbos and Haltech EFI.

In factory production form, the LS platform was available from 293 cubic inches to the 427 cubic inch LS7. Variations of these engines could be found in GM trucks and vans, F-bodies, Corvettes, and even performance sedans like the Pontiac G8 and Chevy SS.

These engines caught on quickly with the street performance and heads-up racing crowd because of their familiar, easy-to-work-on, overhead valve and pushrod design – just like the ever-so-popular small block and big block Chevy engines. The LS family of engines could be the last great pushrod V8 platform to be mass produced.

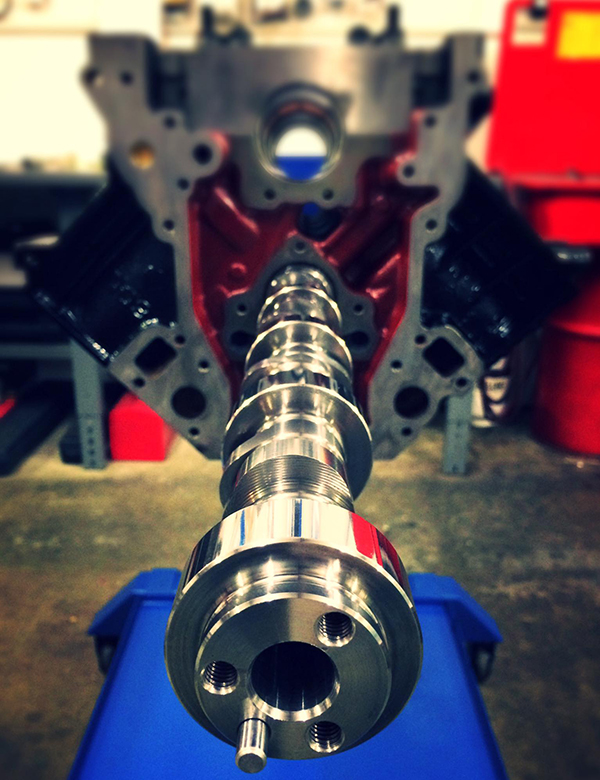

What is so great about these LS engines? First, the LS engine has multiple design features that help it achieve near-big-block levels of horsepower. With a 15-degree valve angle, intake ports that flow 300 cfm and a 55mm camshaft diameter, one can see what the engineers at GM were after when designing these engines – efficiency and performance. They share the same 4.400˝ bore spacing as a standard small block Chevy, but have a raised cam tunnel location, a near 1/4-inch taller deck height, and a rigid 6-bolt main cap design.

These engines were a 100% redesign of the Gen I and II small block. Designers literally took the good from its predecessor and rebuilt it from the ground up using 50 years of learned technology. Even though the external dimensions are small, 454 cubic inches can be easily obtained and heads flowing close to 400 cfm are readily available through several aftermarket companies. All of this makes it easier to achieve impressive power levels, while spending less money.

Many engine builders say one of the best parts of the LS engine is the valvetrain. A 55mm cam diameter makes for more gentle valve events. Even though a solid lifter camshaft will make more power, many LS builds feature a hydraulic roller design. The large diameter, hydraulic roller cam and the factory production rocker arms make for a light and stable valvetrain. All of this makes 7,800 rpm possible with a low-maintenance hydraulic lifter valvetrain. What does that mean for the end user – the racer (and your customer)? It means hundreds of runs without needing to pull a valve cover, much less adjust valves.

Aside from the valvetrain, the LS also boasts very good cylinder head options that are very capable. With only mild porting, even popular factory casting cylinder heads like GM’s 243 LS6 or 823 LS3 castings can support an engine greater than 400 cubic inches with ease. And don’t forget, there is a vast array of aftermarket heads available as well from companies such as Frankenstein, Trick Flow, AFR, Mast, and others.

The LS platform has a 55mm cam tunnel that allows for gentle valve events.

Second is the raised cam tunnel center line from its small block predecessor. General Motors engineers stretched the Gen I small block’s cam height from 4.521˝ to 4.890˝ for the LS platform. This means the days of machining your connecting rods to clear the camshaft on anything with a 3.750˝ or longer stroke are over. The LS design can take up to a 4.125˝ stroke without the need to clearance the rods for cam clearance.

Just how big can you go with your LS? Aftermarket blocks are readily available with a 9.750˝ deck height – a 0.510˝ increase from the factory 9.240˝. Customers also have the option of a 0.390˝ raised cam height. Together, these features allow for an astounding 4.600˝ stroke that makes 500+ cubic inches possible.

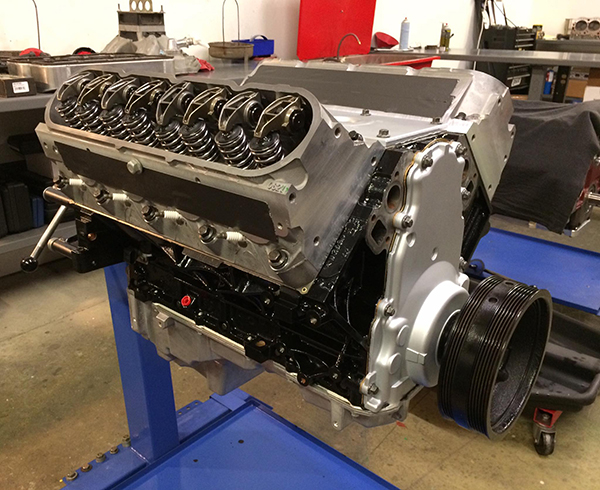

If you’re looking to build a 6.0L LS engine, the first thing you need to do is select the parts you’ll use in your build. The obvious start to any engine build is selecting a good block that will meet your goals. To ensure you can meet those goals, you must know the limitations of the block as well as other components you will use.

In stock form, GM’s 6.0L offers 364 cid from a 4.000˝ bore and a 3.622˝ stroke crankshaft.

For example, cylinder length and how it limits stroke, is one of the factors to consider when starting a build. The length of the cylinder is important because it dictates how much piston will be pulled out of the bore at bottom dead center. The shorter the cylinder, the harder it is to design a piston that maintains stability and ring seal at the bottom of the bore. As a rule of thumb, stay with a maximum of a 4.000˝ stroke on any LS block with a cylinder length less than 5.600˝. This dimension is descriptive of all the factory blocks except the LS7, which has a 5.800˝ cylinder length.

Of course, you’ll also need to pay attention to what kind of transmission is behind your LS. How heavy is the car going to be? What’s the application? Is there a power goal? Is there an ET goal? Once you have those answers, some of the most-commonly used block and stroke combinations for LS engines are the 400-408 cid combos, as well as the 416. Generally speaking, the 6.0L iron block 408 is a great build for a vast amount of goals and applications.

The 6.0L LS is popular because a lot of guys want to run bigger cylinder heads, like the LS3-style stuff. Anything that’s going to get boosted, or anything that’s aluminum that is going to make big power, traditionally, they’re going to go after the iron block as well. It gives you a little bit better platform in most cases to start with, as opposed to starting with a 5.3L.

You could choose to start with a LQ4/LQ9 iron GM 6.0L block. These blocks are commonly found in 2000-2006 GM full-sized trucks, vans and SUVs. In stock form, GM derives 6.0L, or 364 cubic inches, from a 4.000˝ bore and a 3.622˝ stroke crankshaft. While these dimensions allow for great performance, who doesn’t long for more horsepower and area under the curve on their dyno sheet?

With a block picked out, the next components to focus on are the rotating assembly parts. Increasing stroke is the most effective way to increase cubic inches on any given engine. Most of the popular crankshaft companies today offer forged LS crankshafts in varying levels of quality. Most companies offer a good, entry level 4340 forged crankshaft that will support up to 1,000 hp reliably. Many suppliers offer USA forged crankshafts in multiple variations that allow for strength and reliability when making horsepower north of 1,500 hp.

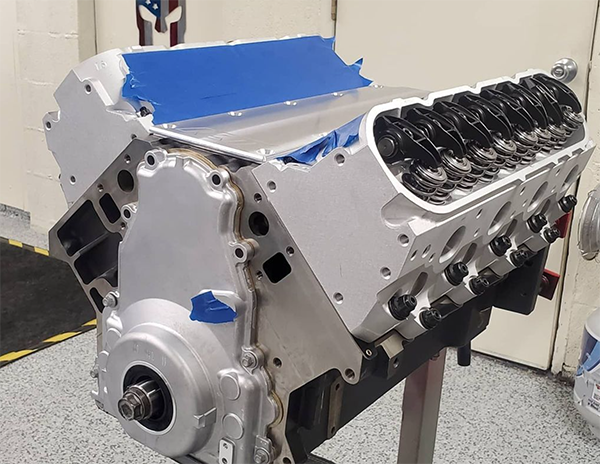

This 406 combo features a Dart LS Next Pro block with a 4.070˝ bore and ½˝ head studs, Frankenstein heads, and a custom Cam Motion billet turbo cam.

A lot of guys might still want to run a factory crank because it’ll take a pretty good beating. This could work, as long as it’s a good core to start with. However, selecting a 4.000˝ stroke crankshaft and 6.125˝ length rods, dressed out with ARP2000 bolts will serve you very well. On top of utilizing H-beam rods, you’ll want to select a set of 4.030˝ bore, 2618 alloy pistons with a ring set to match. If you opt for a +5cc dome volume, you’ll have a compression ratio around 13:1.

Windage control is always important, especially on an LS engine where the crankcase area is somewhat lacking due to the Y-block design. To take advantage of the space given, a good Moroso oil pan and windage tray combo will do the trick. The Moroso pan does a good job of keeping oil in its place with the diamond-shaped trap door system in the sump, while the louvered windage tray is designed to clear extra stroke and control windage more efficiently than the factory windage tray design. To power the oiling system, a high-volume pump will keep the engine lubricated.

With the bottom end selected, now the top end needs some attention. When choosing a proper cylinder head for an LS engine, your customer may dream about installing the largest cylinder head available, however, this is most often the wrong way to go about getting the best performance. To pick the heads that are right for your build, first you must know the different configurations of LS heads that are available.

Olivia Scaffidi’s 6.0L LS features an LQ4 block, a carb setup and cathedral port heads.

First is the original cathedral port configuration. This velocity efficient design is easily identified by its cathedral port opening shape. These heads in the aftermarket world are generally available with 2.100˝ or smaller intake valves and are well fit for a 4.080˝ and smaller bore block.

You also have the rectangle port LS3 cylinder head design. In stock form, these heads have a significantly larger intake port with a 2.165˝ intake valve and a port volume that is over 60cc larger in volume than the cathedral port’s 198cc volume. These heads flow an amazing 312 cfm straight from the factory. You can see why these are a popular choice for racers and hotrodders alike. Because of their intake valve diameter, these heads are best fit for engines with 4.060˝ or larger bore sizes.

You could also opt for the LS7 cylinder head design, which features a rectangle port inlet shape that is similar to the LS3, but is raised .100˝ and is 100% CNC ported. The 2.205˝ diameter intake valve is best fit for 4.125˝ and larger bores and helps this head flow over 370 cfm.

As mentioned earlier, the aftermarket also offers many variations of each head design, big or small. They are each popular in their own way as the general public commonly builds the LS platform from 300 cubic inches to over 500 cubic inches. For a 6.0L 408 build, a set of AFR 230cc cylinder heads with a 328 cfm rating and 2.080˝/1.600˝ valve combination are a good fit for the 4.030˝ bore.

Many builders view the four bolts per cylinder as a drawback of the LS, especially when the small block Chevy had five bolts per cylinder. Despite that being the case, the LS heads out there today are infinitely better.

When tuned well, these engines can make impressive horsepower, but that doesn’t mean these heads are without flaws or areas that could benefit from some improvement. A couple of the weak points on some LS heads are the guides and the valve materials. These guides are powdered metal and very strong, but what happens on those powdered-metal guides is they don’t heat very well into the casting and water jacket. That leads to valve drops down the road. You can opt to put bronze guides in and replace the exhaust valves with aftermarket ones.

These LS3-style heads are some of the most commonly used due to larger port volume.

To maximize the full potential of your cylinder heads, starting with a strong cylinder head is one thing, but getting quality airflow still has to be the end goal. It’s an enormous factor and a differentiator among variations in LS cylinder heads. It’s more about the quality of air and less about trying to hang a big cfm number up there. You don’t want turbulent air. You want to have an equal airspeed around the entire area of the port, as much as possible. A good port job can work wonders.

For the camshaft, a COMP Cams hydraulic roller that provides 255 degrees of duration at .050˝ lift on the intake, and 263 degrees of duration at .050˝ lift on the exhaust is going to keep the valvetrain happy.

Beyond that, cam bearings are one of the issues that these engines see that you can’t really overlook. The factory stuff just is not a good piece. Utilize a set of bearings from Dura-Bond, especially if you start an LS build with a core engine because the cam bearings are typically toast.

Another aspect of the valvetrain you might want to consider are the lifters. GM lifters tend to make noise, even if they’re brand new, so you could ditch those, as long as the budget is there, and opt for a Johnson or Morel lifter. Again, if budget allows, you might want to upgrade the pushrods, the trunnion kit and the rockers as well. In a build like this, 1.7 ratio shaft rockers can be used to compress dual valve springs that keep the valvetrain under control.

It depends on the budget with a lot of this stuff because these things can get out of hand quickly. As long as the budget is there, it’s basically replace everything that you can that could be a weak point or a failure point to give the customer a better component.

Now that you have your parts, make sure they will all work well together. That means you’ll need to do some machining for fitment of the components to have appropriate and consistent internal clearances.

Before starting any of the machining processes, investigate what fasteners need to be replaced or improved over the factory design. Even though the LS design utilizes a 6-bolt main system, the standard 10mm bolt diameter isn’t typically up to the task of keeping the mains in place when trying to produce big-block-level power. To solve this problem, an ARP2000 main stud kit could be swapped in, allowing you to take full advantage of the 6-bolt main system.

With a 4-bolt-per-cylinder 11mm head bolt design, head gasket sealing can become an issue in power adder applications, or even a naturally aspirated engine with compression ratios above 13:1. To alleviate this issue, ARP’s standard 8740 material head stud kit is a good decision. In extreme applications, their ARP2000 or 625+ material fasteners are also a good choice.

Whether its EFI or carburetor, the LS is a great engine platform from 500 hp to 3,000 hp!

Once the fasteners are selected, it’s time to start the machining processes such as line honing the main bores. Not only is this a necessity when the factory torque-to-yield bolts are changed out for studs, but typically the main bores distort after being run for years. After line honing, place the block in a cylinder hone to take the cylinders to their desired dimension with a torque plate and proper fasteners in place.

Before balancing, check the reluctor wheel placement on your LS crank with Goodson’s installation and alignment tool (pn-RRJ-350). Once the precision balancing process and parts weight matching is completed, TIG weld the reluctor wheel to the crankshaft to prevent the wheel from rotating and impacting ignition timing.

To finish the machining process, mock-up your block with rods and pistons to measure deck height on the four corner cylinders of your block. Use this as a guideline to know how far to cut the deck surface on the block. Surfacing should be done using a block fixture to ensure the decks are cut square and parallel to the main centerline.

Aydan Bailey’s twin-turbo 6.0L LS is capable of 8-second passes.

Now that your LS engine is built, we need to feed it. EFI or carburetor? Electronic fuel injection technology has come a long way, and with that, so has the ease of use. Today, several choices of self-learning systems to help build base fuel maps are available. They’ve taken the hard work of tuning and simplified it to require only small changes to get you where you want to be. When using a turbocharger or centrifugal supercharger, EFI is the best way to go to keep an engine happy in all conditions.

Even though installing a carburetor on an engine originally equipped with EFI is considered by many to be sacrilege, it can be done if desired. In a naturally aspirated combination, a carburetor can make great horsepower and be easier to predict in varying weather conditions, while also being more cost effective.

In the end, being able to manipulate the available cubic inches that can be found in the LS series of engines can allow for a myriad of benefits, primarily a high-horsepower LS at a reasonable cost that will require little maintenance and provide great predictability. With an LS, you’re looking at an engine that’s a really solid platform from 500 hp to almost 3,000 hp, depending on boost, budget and your tune.

The hardest thing about LS engines is that there is so much information out there that everyone thinks they’re an expert. Make sure your customer trusts you as an engine builder and understands what you’re doing to make the build work to everybody’s advantage. EB