Joe and Howard Funk were born just 30 minutes apart on September 17, 1910 in Akron, OH. Both brothers seemed to have a knack for all things mechanical, and both excelled in drafting and shop classes in school. The brothers took an immediate liking to flying machines, which were becoming quite popular in the Akron area during that time.

Their folks however, had other ideas, and set them up in the retail grocery business. That proved to be the financial platform the boys needed to pursue their interest in aircrafts.

The boys built their first flying aircraft during the summer of 1934. It looked much like a redesigned piper cub, a popular aircraft of the day. The engine the boys chose for their airplane was a Szekely 3-cylinder radial engine. Admittedly inexpensive, the Szekely was not known for its reliability. Nevertheless, it proved that the boys could design and build a flying aircraft from scratch.

The Szekely engine proved so unreliable it was quickly replaced with a highly modified water-cooled Ford 4-cylinder automotive engine, which was mounted in an inverted position. The Ford engine was modified by the Funk brothers themselves, and proved reliable enough to power the next 60 airplanes the brothers built.

In 1940 the Funks went to the Akron business community and asked for financial help. They could no longer work out of the back of their grocery store. The community responded by raising $78,000 in capital, and the Akron Aircraft Company was incorporated. The Funk’s aircraft manufacturing business was moved to an old abandoned four-story schoolhouse on the northwest corner of the Akron Airport.

Production slowed in the later part of 1940 when it was determined the modified Ford engines required an excessive amount of maintaince. The Funk brothers immediately switched to 75 hp Lycoming air-cooled engines. Unfortunely, they would soon discover that the Lycoming engines also had a design flaw – one serious enough that it caused the assembly line to be completely shut down for a time… until the problem could be fixed. During the shut down, one of the creditors got nervous, pulled his money out of the company, and forced the boys into bankruptcy.

Help came from two Kansas oil field suppliers named Bill and Raymond Jensen of Coffeyville, KS. As a condition of the financial bailout, the Jensen’s insisted that the Funk brothers move the aircraft company to Coffeyville.

The Funk brothers were anxious to resume building aircrafts so they agreed. Production began in Coffeyville in November of 1941. Three planes were built and shipped to South America before the bombing of Pearl Harbor halted private aircraft production.

By 1945, the cost of a new Funk airplane had reached $3,700. Competition was keen from a host of newly formed civilian aircraft companies, and the government was selling surplus aircrafts for $200 each. Another problem arose when the government took away the flight training money from the G. I. Bill. The returning soldiers from the war could no longer learn to fly free. The Funk brothers sold just a dozen planes in 1947. At the end of 1948, Funk aircraft production ceased for good.

After the Funk brothers found out they could no longer sell airplanes, they turned their efforts to farm tractors. In 1948, Ford tractor owners were looking for more horsepower. A standard Ford tractor was 30 horsepower and could pull only a two-bottom plow.

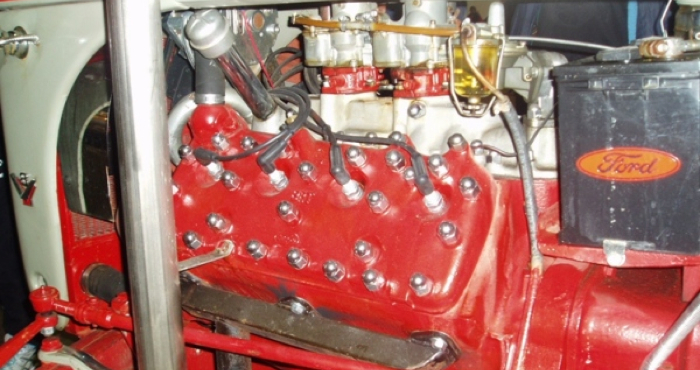

The Funk brothers began fitting Ford tractors with 6-cylinder Ford industrial engines that produced 95 horsepower. It was soon after that the Funks began offering tractor conversions using the 100 horsepower Flathead Ford V8s. Now a farmer could easily pull a three-bottom plow.

The Funk brothers ran ads in farm journals with coupons. The ads advised that if a farmer wanted a new tractor converted he could take the coupon to his local Ford tractor dealer and have the dealer call the number in the advertisement. Ford soon found out about the conversions and immediately sent memos to all of its dealers saying if the conversion was performed to immediately tear up the factory warranty.

In fact, Ford was preparing to sue the Funk brothers when several of the conversions developed rear end failures. Further testing showed that the Ford rear ends were defective from the factory. A compromise was worked out and Ford dealers became authorized to make the conversions at the dealerships.

Kits could be ordered from the Funk Aircraft Company with either the 100 hp Flathead Ford V8s or the Industrial 6-cylinder engine. The original 4-cylinder tractor engine was removed and sent back to Ford in the same shipping crate as the conversion kit came in. Ford then sold the engines as replacement engines for industrial applications with a full factory warranty.

The Funk brothers stopped offering conversion kits around 1953 and the company closed soon after. In later years, the Funk conversion tractors were held in low regard because the production had stopped and repair parts were difficult to find. Used Funk tractors became so difficult to sell that many were converted back to the original 4-cylinder engines.

Today, however, the original Funk Conversion tractors are highly collectable; especially those with the Flathead Ford V8s installed. They’re so popular, in fact, that you can again buy the conversion kit to put a Flathead Ford V8 into a Ford N series tractor.

If you own a few acres in the country what could be more fun than a tractor / mower combination powered by a Flathead Ford V8? Add a pair of Fenton Headers along with a pair of Smithys… and mowing will never be the same again.