Modern diesel engine platforms offer a great source of power potential regardless of the manufacturer. I suppose that is why the mid-size diesel truck has become so popular among the younger generation.

Take an engine that already makes power and find ways to make more. Turbocharged diesel engines have a huge amount of power gains when “tweaked” in the right direction. The same can be said for pulling trucks and drag racers with diesel engines. In theory, the diesel engine comes to “life” when combustion temperatures reach 2,500 degrees F.

When you change injection timing, fuel and boost, the angry giant comes to life. The object of the game, of course, is to tame the angry giant in hopes of obtaining dependability, longevity and efficiency. There are numerous internal engine parts available in the aftermarket to fit not only the needs of hot street trucks but also for pulling, drag racing and over the road transportation.

Pistons are offered in a variety of configurations depending on the application. Most aftermarket pistons for diesel applications are cast aluminum. Cast designs offer great longevity and durability for everyday driving or work applications. They also offer a steel insert for the top compression ring that provides additional strength for street, strip and pulling applications up to 1,000 hp.

The piston bowls now have design features that reduce erosion issues caused by high pressures, long duration and advanced injection timing. The piston skirts are also coated for reduced drag and scuff resistance.

For higher horsepower applications such as pulling and drag racing, a forged piston is typically a better choice. In gasoline applications, forged pistons are the choice for high performance engine builds. However, the diesel piston is subject to extremely high temperatures and pressures for extended periods of time. The key to longevity of the cast diesel piston is the steel top ring insert that protects the top ring groove. Without the insert, the top ring groove will have accelerated wear and lead to increased blow-by and decreased performance.

The forged piston is used in performance-only applications (limited mileage) because of the accelerated wear effects of the top ring. The forged piston has a hard anodized coating for the top ring groove but only serves the purpose of a little added longevity and some increased durability. Because of metallurgical issues, a steel insert cannot be placed in a forged piston. The bonding becomes an important issue for heat transfer and controlling the expansion of the two materials.

Keep in mind that if you are considering using a forged piston for your application, sooner or later it will need to be replaced. The ultimate choice for any diesel application would be an all forged steel piston. Because of the steel construction there are no issues with erosion of the piston bowls from high pressure and advanced injection timing. The steel ring grooves are great for durability and longevity. The steel piston was adapted for on-road usage.

With growing emissions demands of Class 8 trucks, heat and longevity became an issue with cast pistons. Engines run higher temperatures and have extreme demands placed on them from the emission components placed on the engine. Manufacturers incorporated the use of a forged steel piston to increase longevity and dependability to achieve the million-mile mark for a rebuild. Because the steel piston worked, they have been adapted to racing applications.

There are disadvantages to running a steel piston, however, the biggest being cost and availability. Another downside is weight. But, with the right design, the piston and pin combination can be made to match an aluminum piston. The catch is, it takes a dedicated design for the application and currently steel pistons aren’t being produced as one-off custom batches. The steel trend is growing and we can expect to see more applications of steel pistons.

Second, connecting rods are also a concern when making big power. For years, the diesel connecting rod was made of forged steel. As technology developed, powered metal offered a more cost effective solution, which has proved to be equally durable for OE applications. But when power is increased, powered metal connecting rods can fail because they cannot handle the torque loads and cylinder pressures.

Aftermarket manufacturers offer 4340 forged rods with the addition of chrome, nickel, molyand vanadium. H11 tool steel rods are also offered, but can be very expensive. H11 tool steel is a deep hardened steel that will have minimal size change during the heat treatment process due to its balanced alloy content. H11 offers great resistance to thermal cracking, fatigue and shock. Aftermarket rods offer a lifetime of use and can be reconditioned at a fraction of the cost.

As for crankshafts, diesel engines come standard with a forged crank with either a 4340 or 1020 alloy. The integrity of the crankshafts is usually not an issue when making big power. However, a forged crankshaft can only handle so much before it begins to fail under the harsh conditions of a diesel environment. There are billet crankshafts being produced for mid-size diesel engines such as the Cummins and Duramax to handle the enormous power gains of 4,000 horsepower and climbing.

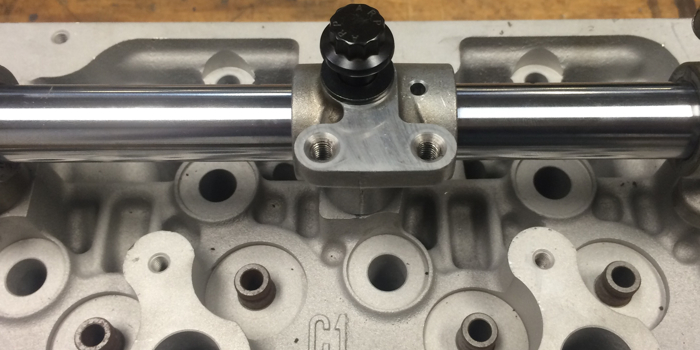

Third, as the engine revolutions increase the valve train becomes unstable. Diesel engines were designed to operate at low rpm. When a performance camshaft is installed and the engine operates at a higher RPM then the components of the valve train begin to fail. Aftermarket manufacturers have come up with various solutions to help stabilize the top end so maximum power can be achieved with reliability.

Valve springs will need to be changed and there are many designs available to fit most applications. An increase in valve spring pressure will lead to the need for a bigger diameter pushrod. Most modern day diesel engines incorporate the use of roller lifters, which will fail so they will need to be upgraded. Thicker wall rocker shafts and valve bridges are available to help control deflection from increased demands of the other components.

Keep in mind that aftermarket parts are made of strong materials to withstand the harsh environment diesel engines are subject to. The materials used to manufacture these parts will determine the price. Connecting rods for mid-size diesel engines can be upwards around of $4,000 a set.

Because diesel engines have become more commonly used for performance there have been many technological advances for modern day parts. Whether the application is for stock or performance use, there can be an increase in longevity, efficiency and reliability.