The parts you put into your engines and keep on your shelves for resale are far more than just generic automotive components. You need them to be what you need, where you need, when you need. They’re not just plastic and metal inanimate objects – they’re your reputation.

Maintaining that reputation for excellence means you have to select the right product for the right customer and the right engine. Each customer has his or her own expectations for the components in the engine – so do you. What is it that makes a part the RIGHT part? Why, how and from whom do you buy?

The traditional two- and three-step distribution model has, in many cases, been supplanted by very untraditional shopping methods. The way you shop and the way you buy continues to be a very complex part of very complex market.

For more than 55 years, Engine Builder’s mission has been to help industry professionals make more money and serve their customers more efficiently. Since we really have two audiences – the engine building and machine shop owning professionals and the parts and equipment manufacturers and suppliers who serve them, it’s imperative that we help all parties understand the dynamics in the business. We understand that the variable – the engine builder’s customer – can be a wildcard that throws any expectations out the window.

We asked our readers to help us identify the decision making process. On one hand, they’re looking for the best deal to maximize profits. On the other hand, they have to meet the demands of the engine build. This research study profiles a variety of engine parts and types of equipment. The nature of the questions, we feel, did a great job convincing survey respondents to tell us the truth, not what they expected us to want to hear.

This is the second consecutive year for this study and we are able to make some comparisons year over year.

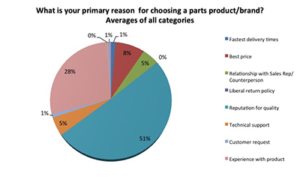

We asked readers what their primary reason is for choosing a particular product as well as where and how they like to buy parts. What are the factors that influence our readers’ decision making processes most significantly and how do THEIR customers influence those purchasing decisions?

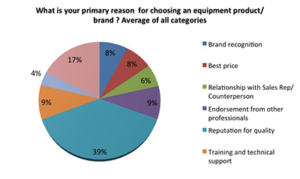

Some interesting conclusions can be drawn about the factors engine builders consider when buying parts. The top three primary reasons for choosing one part over another stayed exactly the same this year. Averaged across all parts and equipment category, the top reason for choosing a product is Reputation For Quality (51 percent), followed by Experience With The Product (28 percent) and Best Price (8 percent). Technical Support (5 percent) and Relationship With Sales Rep/Counterperson (5 percent) were tied (last year, tech support was a little more important than the relationship); Customer Request (1 percent) is down slightly; Fastest Delivery Time stayed steady (1 percent); and being an OE Supplier (1 percent) gained a bit of importance. Overall, a Liberal Return Policy (0 percent) remained irrelevant as a reason to buy – interestingly, so did Celebrity Endorsement (0 percent).

We were able to present detailed reports on several of the individual product categories of interest to our advertisers, explaining why our readers choose a particular product or brand. A complete downloadable report is located here. Our survey studied many, many different specific product categories, and while they are not included in this report, the information revealed in these pages is based on general buying behavior.

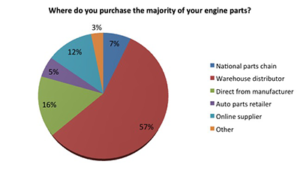

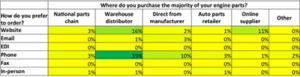

According to our survey, the majority of professional engine builders continue to prefer to buy from a warehouse distributor (57 percent). Buying direct from the manufacturer increased in popularity (16 percent, up from 14 percent), while online suppliers (12 percent, down from 15 percent last year) are somewhat less popular. National parts chains (7 percent), auto parts retailers (5 percent) and “other” (3 percent) are sources as well.

When it comes to placing engine parts orders, the majority of engine builders want to talk about it – a whopping 58 percent of respondents say they prefer to place an order on the phone – this is almost 10 percentage points higher than last year. It could be that texting is accounting for some of the increase (technically it IS on the phone) but we feel “text-only” orders would probably be used with local suppliers who might be able to drop off a last-second part needed immediately. While the same number say they prefer to shop online (web ordering accounts for 38 percent of the activity again this year), email fell 4 percentage points in popularity. Face-to-face communication isn’t dead, as 4 percent (same as last year) say in-person sales is their preferred method of conducting business. Fax and EDI again combined for less than 1 percent of the responses.

Our research again supports the belief that where you like to shop determines how you prefer to order. The favorite combination of supplier and order method is calling up your warehouse distributor – 39 percent of all respondents prefer that (up from 34 percent last year). Sixteen percent prefer to use the WD’s website (down from 18 percent last year), while 11 percent prefer an online supplier’s website (steady from last year).

Whatever the source, ideally, engine builders stress the importance of one-stop shopping. Eighty percent say it’s extremely important or important to be able to buy what they need at once. Seventeen percent say it’s not important and 3 percent say one-stop shopping means absolutely nothing. For those who value the convenience of getting the whole order from one source, they feel a warehouse distributor is their best bet.

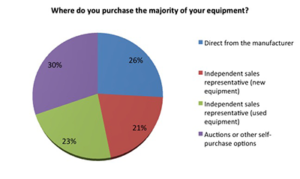

Buying equipment is a bit of a different situation than parts purchasing, of course, because it’s rare that engine builders and machine shops make quick decisions on these capital investments. However, equipment suppliers must still sell, so how do our readers buy?

The vast majority of new and used equipment is sold by independent sales reps (23 percent of the time with used equipment and 21 percent of the time with new). Customers tend to buy direct from the manufacturers 21 percent of the time. About a third of the time, customers rely on auctions or other self-purchasing options.

Everyone wants to be assured that the products they buy are right for their needs – and it’s both easier and more difficult than ever to get information to support purchase decisions. Easier because of analysis (including detailed catalogs, sell sheets, technical documentation available from a variety of sources), advice (manufacturers reps, independent sales reps and knowledgeable counterpeople ready to handle your requests) and assistance (installation, maintenance or follow up questions). Harder, perhaps, because anyone can pose as an expert.

Even though technical support may have fallen off as a primary reason engine builders buy a particular brand, it’s more important than ever to engine builders to know that is available – and be accurate. Nearly 87 percent of survey respondents say tech support is an important or extremely important factor in their purchase decision – that’s up from 83 percent last year. “After sale support” in general is important or very important to 94 percent of our survey respondents.

As we indicated, the majority of our readers tend to prefer buying from a knowledgeable WD and would stay with that WD if their regular customer service rep or sales person were to leave and go to another company. When asked, “If your WD sales rep left today and went to another company, would you follow that sales person and show loyalty to them or would you remain loyal to your WD?” Fifty-one percent of respondents said they would stay with the WD, while just 6 percent said they would follow the sales rep. Last year, 39 percent said they don’t quite know what they would do – this year there’s even more uncertainty. A higher percentage (43 percent) tell us their loyalties are to their customer, and they could probably be influenced by another supplier if they had the needed parts.

With the performance industry, of course, the right part is critical. Consumers may be swayed by celebrity endorsements, but as we indicated earlier, that’s NEVER a primary reason our readers say they would choose a part. Similarly, when they were asked if sponsorship of television programs influence their purchases, no one said “always,” only 1 percent said “most of the time,” and just 5 percent responded “about half the time.” About 39 percent said it’s “sometimes” a factor and 54 percent say it’s “never” an influence.

A company’s activity in racing series is a little more important to engine builders. We asked, “How much does a brand’s contingency program involvement influence your selection criteria?” and got some interesting responses. It’s always a factor to 5 percent of respondents; important most of the time in 19 percent of the cases and about half the time in 17 percent of the cases. The majority – 59 percent – say it is a factor only sometimes or never. Obviously, if you’re building to particular series specifications or dealing with a racer who wants to capture contingency dollars, this topic is of more importance to you than some of your industry colleagues.

For readers of many of Engine Builder’s sister publications (Tire Review, Underhood Service, Import Car, and Brake & Front End) getting vehicles in and out of bays means that parts availability is sometimes more important than price. Engine builders often face different circumstances – your customers might not be as demanding about WHEN they get it, only THAT they get it (often on their own payment schedule). Same-day delivery versus one- or two-day delivery is usually not a key factor in a buying decision. Only 50 percent of readers say same-day delivery is important or extremely important – an equal amount say it’s not important. The key, they tell us, is having the right part for the application.

As it turns out, if a certain brand is temporarily unavailable from a preferred vendor, 21 percent of respondents would postpone the build. The customer would be invited to purchase his or her part from whatever source they could find in 2 percent of cases. The decision to buy online or from a mass retailer would be used in 10 percent of cases while the vast majority (67 percent) would substitute the missing part with an equivalent product.

When sourcing a part, its country of origin has a strong impact on the purchasing decision – however, it’s not as strong a factor this year as it was last year. When asked “Does ‘Made in the USA’ affect your buying decisions?” Sixteen percent of respondents said “Always” (down from 26 percent last year) and 48 percent said “Most of the Time.” Another 19 percent said it is a factor “About Half the Time” and 16 percent said “Sometimes.” Only 2 percent of respondents said it “Isn’t a Factor.” These numbers may be tied directly to fears about trade battles and supply issues. In our global economy, some parts are simply not available from U.S. suppliers – and perhaps not available at all. Engine Builder will address the topic of the world economy in an upcoming issue.

We get it – customers pay the bills. Hopefully, they know enough about what they want from an engine to either guide your build sheet or understand what they DON’T know to stay out of your way. One of the leading complaints we hear from Engine Builder readers is that search engines, social media and online forums make everyone think they’re an expert. Sometimes this translates to exercising influence over your purchase decision. Eight percent of survey respondents say customers have “a great deal” of influence; 18 percent say “a lot;” 46 percent say “some;” 18 percent say “a little;” and 11 percent say “none at all.”

Readers say their customers might actually be getting more discerning about products in cases where they make the purchases. While 43 percent say quality is the most important factor, 35 percent buy on price. Product performance is cited by 13 percent as the primary factor. Brand reputation (8 percent) and support (2 percent) close out their influences.

Private label and house-brand products are often a very important part of an engine builder’s tool kit when it comes to building a customer’s perfect engine. How do customers perceive these parts?

We can report that 9 percent see them as better value than brand name products; 33 percent see them as equivalent to brand names; 44 percent characterize them as acceptable economic products; and 14 percent perceive them as “cheap knockoffs.”

Educating customers about the value of house and private label products is often the responsibility of the engine builder, and can be a difficult, but necessary part of customer service. How do professionals get information about new products? We continue to be excited by the results of this question.

Though many outsiders have long proclaimed the death of print, a solid 68 percent of respondents say they still learn about parts and products through print magazines (although this number is down from 78 percent last year). Fifty-seven percent use internet searches; 51 percent visit manufacturers’ websites; 50 percent get information from parts suppliers; and 45 percent use tradeshows for their information gathering needs. Digital newsletters (36 percent of respondents), magazine websites (28 percent), digital magazines (19 percent) and videos (15 percent) offer guidance (blatant self-promotion: go to www.enginebuildermag.com to learn more about what we have in all of these formats). In addition, TV Shows (14 percent), Training Seminars (14 percent), Chat rooms/forums (13 percent) and Webinars (12 percent) can fill training needs in some cases.

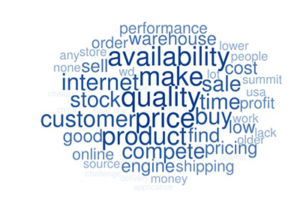

In addition to answering our questions, we offered survey respondents the chance to tell us in their own words their greatest buying/sourcing challenges.

Here are some of the comments:

Availability

• “Since I specialize in ‘any engine old and unusual,’ I am constantly trying to source odd parts. I have a number of people who know somebody who might have what I need.”

• “Out of stock and backorders for performance parts is a problem. It seems like my suppliers are making smaller batches and carrying less inventory.”

Internet Sales

• “A lot of the time, my WD can’t sell parts to me low enough for me to mark them up and still sell at retail. Competing against an 8.5% no sales tax advantage is killing me.”

Technical

• “I’m just not always sure of the technical features and benefits.”

Money

• “I have to watch not to over-build what the customer can afford.”

• “Getting the customer to agree to buy top quality parts.”

Luckily, some engine builders say “challenge” is an overused word. “I honestly can’t think of any real problems – things are going real well.” That’s the positive attitude we like to hear at the end of the year. We’ll report next year on whether those good times have continued.