Are You Willing to Go Beyond the Engine Build?

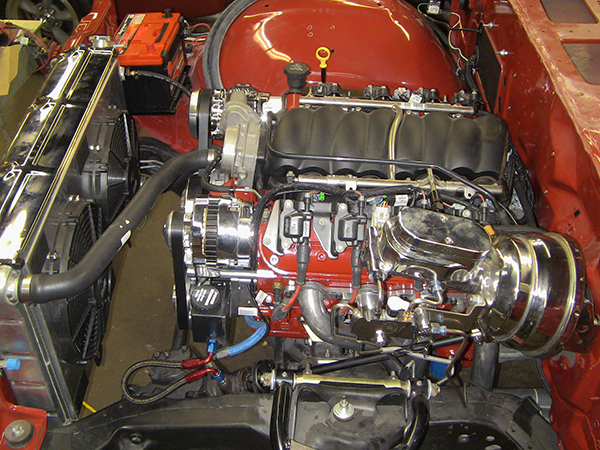

Does it just work, or is it a work of art? We’re talking about a well-detailed engine tucked between spotless fenders with freshly restored components. When it comes to engine installations, I admittedly picture a classic American car or street rod showing off its factory engine colors with a few polished components in just the right places.

Obviously, engine installations can, and do, take place in everyday vehicles as well. Those two engine installations might look drastically different, but the idea and theory is the same no matter what engine you’re installing or what vehicles. The difference lies in the details.

A detail not to overlook from the engine builder’s standpoint is the extra revenue stream your shop will have if you choose to perform engine installations.

“You have to have different revenue streams,” says Chris Wright of Pro Car Associates in Akron, OH. “Pro Car got started by building engines and race cars. Then it migrated into automotive and there became two sides of the business – the automotive repair side and the engine machine shop and engine building. I’ve always kept all those different areas of our business as a strong point. Doing installations goes in line with being able to build an engine. It was just natural progression to start doing all these custom installations and modifications in vehicles.”

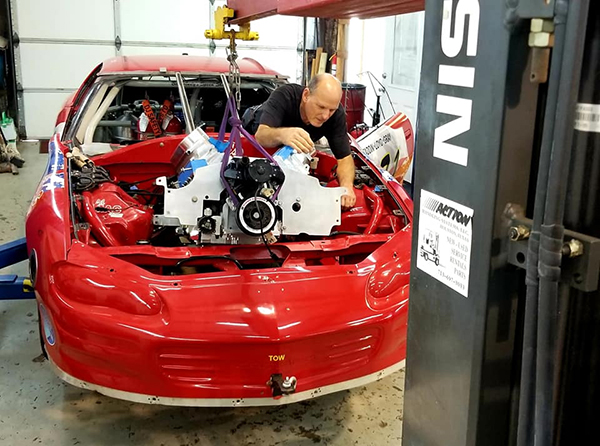

Aside from the decision to add engine installations to your business or not, you’ll need to consider the additional skill sets required, additional tools and equipment and your shop’s space available to have entire vehicles inside.

“You’re going to have to have people who are more inclined to work on those types of jobs,” Wright says. “If you’re going to customize vehicles, build custom turbo systems, do LS swaps, build a car, and install that engine and everything around it, those are different skill sets you’ve got to have in your people.

“You also need to have the space in the shop to have a car in there. The facility becomes the limiting factor for a lot of things. All the different types of work you do requires certain areas like a fabrication area, a machining area, a place for general work, assembly work, and engine build work, not to mention the vehicle itself.”

Another aspect of engine installation work is you’ll almost certainly need to modify things in the engine compartment, requiring welders, grinders, cutting tools, and more to accomplish the job the right way.

“If you’re going to do this kind of work, your basic requirements are a mill, a lathe, a welder, a vertical saw, a horizontal saw, grinders, sanders, different types of drills, and then all the tooling,” he says. “That’s the basic, first level.”

Assuming you’ve got the right set up and people in place to add installations to your shop’s repertoire, the next challenge for an engine builder performing an installation is the customer’s expectations. Many customers do not take into account the removal and replacement and don’t realize all of the additional steps that take place during the process. If you are going to be performing the installation, identifying all of the additional opportunities or required items that you will run across should be part of the initial conversation with your customer, prior to beginning any work.

“It starts with the counter person discussing with the customer what their needs are,” Wright says. “We consult with them on what they want to do, because there’s all kinds of options available. It’s understanding what their needs are and what their budget can handle too. There are different scenarios and as a business we have to be flexible and adapt to whatever those needs are.”

As will be the case with any engine work, you will have to educate your customer on all of the things that can occur during engine installations and be clear about the cost expectations of that portion of the job.

Cleaning is one of the initial steps when the engine is out. Much of that goes without saying on a classic car, but that’s not always the case. It could just be a daily driver and the owner isn’t concerned about the remainder of the engine compartment. But this is still a good opportunity to sell them on at least a basic degreasing and cleanup and let them know that this is more beneficial than just looks.

A basic engine compartment cleaning will make installation easier for you, but will also make future work easier for anyone else working on the car, with years of grease, grime and potentially rust removed. It will also prevent them from blaming your new engine for a stray drip or drop of oil or coolant left on the frame. Years of buildup from an old, leaky engine is there to stay until it’s cleaned, and buildup in cracks and crevices everywhere are almost impossible to clean out with the engine installed.

A common problem is that oil and grease attract and hold dirt, and over time a buildup will eventually clog drain holes and channels that are built into frames and body work, ultimately holding water. This will slowly rot and corrode away even the best of metals. A good engine compartment cleaning is as important as any other vehicle maintenance.

The options during an engine installation can go in stages, with cleaning being the first. Engine compartment detailing is not only attractive, but profitable too. The sky is the limit with this type of service, from cleaning and painting the frame to cleaning and refinishing everything from the firewall and fenders down, and it really goes quicker than you think. You’ll be hard pressed to have any takers on this for an everyday driver, but on a classic car this can be an easy sell.

If you’re going the path of detailing and painting, once the engine is out, it doesn’t take much to remove wires and hoses from the firewall and inner fenders, or even remove the inner fenders if they bolt on. It’s also surprisingly easy to pull wiper motors and brake cylinders, or any of the other accessories that are bolted on in the engine compartment.

Outside of cleaning and eventually painting, the two main factors you will have are the hardware or components that you can recommend for replacement before you even begin, or the things you run across during the job. When you’re reviewing everything that is going to get done before starting the job, you can identify and list out things that need replaced such as hoses, clamps, battery cables and fasteners. Engine mounts are almost always a given and don’t forget exhaust studs and hardware if someone is sticking with the stock manifolds. It’s also a good time to replace a rusted-out battery tray.

Things such as a new washer hose, wiper motor bushings, ground straps, wiring harnesses, are all available if customers desire them and easy to install with the engine out. Even if they don’t opt for much new hardware, there are things you can do like re-wrap a few wiring harnesses with new electrical tape, use cable ties to neatly and evenly secure wires and hoses, or install a firewall grommet for their gauge wiring and lines. The little details make all the difference.

Take for instance, priming and painting bolts and fasteners. These parts are usually in pretty good shape, and once they are cleaned up, bead blasting or wire brushing them gets them ready for priming and painting. Punch a bunch of holes in a cardboard box and stick all the bolts in for priming and painting. You can get extremely particular by taping your sockets or wrenches to eliminate marks on freshly painted bolts, but generally speaking if you don’t over torque them, you’ll hardly see a mark. It adds an amazing, nice touch to an engine compartment.

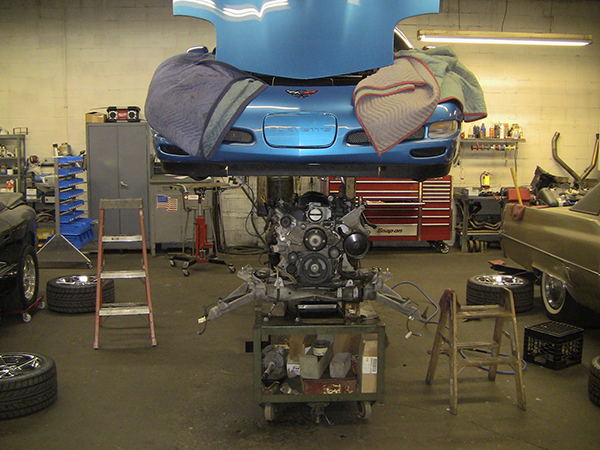

“We may start with the engine build and get that built, and once the engine is ready, we’ll get the car,” Wright says. “If it’s an LS swap turbo build, for example, in an older car, we want the car not finished. We don’t need the front fenders on or other aspects of the car finished because we may still have to cut firewall. We may have to do things to the floor or modify some of the chassis, whatever that may be.”

When it does come time to install the engine, you’ll need someone who is capable of seeing 10 steps ahead to understand how it will fit in the car, and you’ll likely want mock ups of the engine and transmission so you’re not taking those large, heavy components in and out repeatedly.

“The guy building the engine isn’t necessarily the one putting it in the car,” he says. “So you’ve got to have an employee who understands the geometry – the pinion angle, the ride height of the car, the engine location in the car to give you the correct pinion angles. Engine location becomes important as well as mounting and drive line clearances. Also, is the transmission that we’re going to use going to clear? Do we have to modify the floor plan? You have to be a person that visually can start looking 10 steps ahead. Every car is different.

“You really have to start laying it out from the foundation of the car – chassis, tires and the ride height. Once you have your engine location you can set your pinion angle and figure out that line from crankshaft all the way to pinion. Then you put your tranny case in there. A lot of times you’re going to have to have mock up stuff. You’re not going to put the actual, physical engine in the car and the actual tranny in the car, because you’re going to be pulling it in and out. You’ll want a mock up block, a mock up tranny case, etc. so they’re easy for one person to pull in and out of a vehicle.

“Next, you’ve got to think about routing coolant lines, fuel lines, brake lines, all the electrical systems. With the electronics, we want to make sure we have things separated from a control standpoint and things grounded properly with good ground points.

“The guy doing that engine installation needs a unique skill set, honestly, because you have to see the big picture. You truly have to have a better understanding of how everything operates.”

Of course, the unforeseen can always happen and it’s worth mentioning to your customer to expect the unexpected. Worn flex plates or flywheels, worn out clutches, leaking pressure switches or sensors, broken bolts or brackets – any of it can happen. They should always factor in additional cost.

Customers may also want to consider a new thermostat, fuel filter and air cleaner. Does the radiator need flushed? What about the hoses and belts? This is also the ideal time to recommend a carburetor rebuild on an old car, or perhaps an upgrade to fuel injection. It’s also the perfect time to add an oil cooler or even a transmission cooler. It’s always easier to add accessories when you have the extra room to work.

It’s pretty clear that adding services such as engine installations can open up a world of opportunities. Is your shop willing to do the work? EB