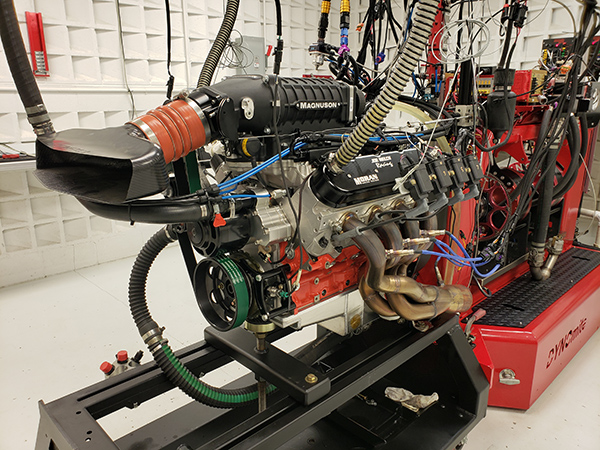

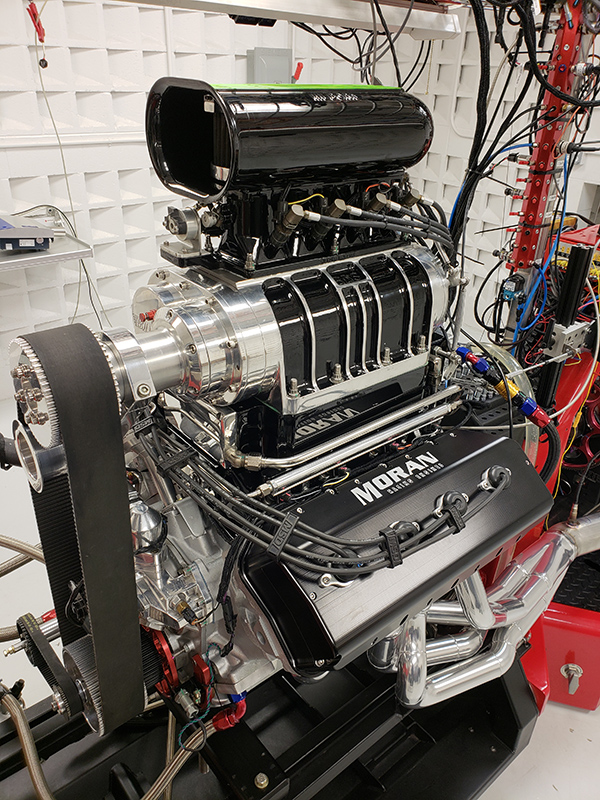

As far as Mike Moran knows, his shop, Moran Motorsports in Taylor, MI, is the only shop in the country with an engine dyno and a hub dyno that are both capable of handling more than 6,000 horsepower. Each of these dynos are beneficial tools to Moran’s high-horsepower engine business, and while the horsepower level of these dynos might be more than other builders need, the combo of an engine and hub dyno might be a huge opportunity for all engine builders.

As most of you know, an engine dyno is an imperative tool for professional engine builders to dial in engine combinations and work out any kinks or make final adjustments, as well as knowing whether you hit a specific horsepower number, before handing over a finished engine to a customer. Conversely, the hub dyno is a tool that allows you to dial in that same engine combination in conjunction with the entire car in will be in. Both have advantages and different features that are beneficial to engine builders and customers alike.

I recently spoke to Mike Moran about his new 8,000-horsepower capable Mainline hub dyno, as well as his 6,000-horsepower Land & Sea engine dyno, to get his perspective of the two tools and how it’s impacted his business.

“The engine dyno is pretty much what we use for R&D,” Moran says. “When you’re looking for repeatability of 2-3 horsepower, that thing does a really good job. It’ll even measure small gains and losses such as valve lash, which will change it 6-10 horsepower. You’re not able to do that on a hub dyno. Not that it’s any less accurate on the load cell, it’s just that you have all these other factors involved with it such as converter charge pressure, what the temp of the trans was, etc.

“When you’re on the engine dyno, you can just measure the engine and everything about it and you can change a camshaft and know if there was 20-horse difference. You might lose that on the hub dyno just through a back-to-back pull if your trans fluid was 80-degrees hotter than the first run due to slippage. The engine dyno is really important to try to work a custom combination out. If it’s something we’ve done to death and we’ve done 1 million of them, then you could probably go right to the hub dyno and not worry about it. But, if it’s something custom and the intake is different, the cam is different, compression is different – it’s best to work it out on the engine dyno and figure out what it wants before you put it in the car and put it on the hub dyno.”

For many of those reasons, Moran recommends running an engine on the engine dyno before you put it in the car. That way, you can better pinpoint where any losses or issues are stemming from – the engine or the car.

“The car has so many different facets – electronics, the transmission, fluids, etc. You’ve got to be able to make sure you’re putting in a good piece so that you don’t start thinking the motor is the problem,” Moran says. “I’ve got my own standalone EFI system on the engine dyno, and I have hundreds of calculations for different combinations and I can run any combination with a pretty decent and safe tune up. When it leaves the dyno, if there’s no problems and it goes in the car and we’ve now got all kinds of problems, then you can separate it and know that it’s something such as how it got bolted in the vehicle, or the transmission, or your converter, or electronics, whatever, because it ran fine over here.

“Sometimes, I get an engine on the engine dyno and realize the cam sync is off. If the cam sync is off mechanically, they have to be fixed. Taking it back out of the car or messing with the crank signal, or any leaks – who wants to try and fix that stuff in the car? I’d rather make sure it leaves here knowing the engine is sound. It’s also nice being able to see the horsepower and the direct correlation to what you lose in the driveline. That’s the other piece of information people don’t know. Your engine might make 4,000 horsepower on the hub dyno, but how much did it make on an engine dyno? How much would you make getting rid of all the parasitic drags? Then, you have a way of working out the efficiency of the car.

“Most of those things are anywhere from 12%-15%, but if you’ve got a customer who lost 30%, wouldn’t you want to figure out where it’s at? It’s a real nice tool when you leave the engine dyno with a set number, and then seeing what it makes on the hub dyno will tell you a lot about efficiency and the drag of the components in the car. I think it’s important to have a dyno for both the engine and the car. Just like anything else, you’ve got to do one before the other if you want to have less problems in the end.”

Having made that decision for his shop about a year ago, Moran purchased a Mainline hub dyno capable of 8,000 horsepower. He knew it would be good for business, but what it actually did for his shop was beyond his expectations.

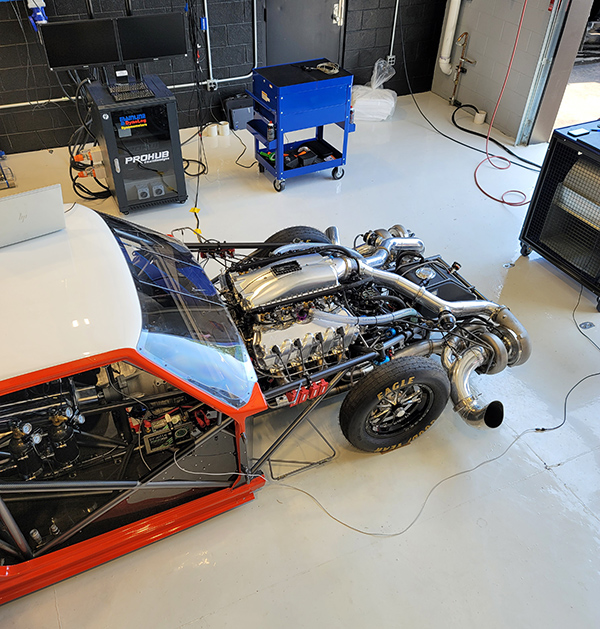

“A lot of guys don’t want to run an engine on an engine dyno because there’s too many things that are integral to the car,” he says. “For example, something that’s turbocharged has all the plumbing and exhaust and the turbo mounts and all that. For nitrous applications and blowers, they should really be run easily on the engine dyno. I think the biggest thing for customers is they just want to run the car versus spending the extra day fabbing everything onto a dyno cart and reenacting the car on an engine dyno. I wasn’t able to do that prior to getting the hub dyno.

“Now that it’s here, I’m realizing most people like to run their cars on the dyno. We’ve got that thing booked at least four out of five days of the week. I just thought it was going to be mostly for my engine customers who don’t really want to run on an engine dyno, but want to run their car. It turned into a lot more.”

What it turned into was additional customers, and new customers Moran wouldn’t have had otherwise. It also opened an entirely new revenue stream for the shop.

“Having the hub dyno has added non-customers,” Moran pointed out. “Now, we’re making customers out of people who aren’t even engine customers. People are coming here and running their combinations in their cars from all different forms of racing. We’ve also hooked in wifi and ethernet cables for guys who are tuning from out of state. We’ve got a guy out of Texas who’s doing a bunch of Nissan GTRs here. It’s easier for him just to have customers come over here and he logs on to our dyno and their Nissan computer and he just runs and tunes it right from Texas. We get paid the same either way.

“It works out really nice because this opens up the market to somebody we would’ve never met or talked to. I didn’t really anticipate this. I thought it was just going to be our customers and I did it mostly to benefit our customers, but now it’s opened up for people all over the world who can log on.”

In fact, when Mike purchased his Mainline dyno and it was done and ready for testing, he got to do this exact thing from his shop in Taylor, MI by running a Moran customer engine/car on the dyno there in Australia.

“We stayed up most of the night and tested the dyno running Rob Campisi’s car, and that thing made just shy of 4,000 horsepower,” Moran says. “It was cool to test one of our customer’s combinations on our new dyno.”

According to Moran, the cost to customers to run their combos on the engine dyno versus the hub dyno are relatively the same. The biggest difference is really effort and time.

“It’s pretty much the same price, but I think the bigger value for a guy who doesn’t have us build an engine would be the hub dyno, because you can be in and out of there in the same day,” he says. “Whereas, the engine dyno usually takes a half day to set everything up and then another day to run it. For that reason, I think the bigger revenue would be from the hub dyno. However, the engine dyno is a necessary tool for any professional engine builder. You’ve really got to have an engine dyno and a way to pick apart the combination and look for improvements. I think the hub dyno is just the icing on the cake and it opens up the door for revenue outside of engine building. That’s a big thing, but you can’t be a professional engine builder and not have a good engine dyno.”

While Moran opted for the highest horsepower rating you can get from Mainline, it’s likely not a set up for every engine shop.

“It just depends on your wallet, I guess,” Moran says. “The horsepower level doesn’t affect the accuracy because it’s still the same load cells. The majority of everything we’ve run has been 4,000 horse and less. The hub dyno doesn’t care if there’s a Yamaha scooter on there running 5 horsepower or something making 5,000 hp. It’s still measuring load.

“Mainline made this dyno so that it was switchable. There’s four large retarders, and for the most part, you run on two retarders all the time for your street cars with 1,500 horse. When you go above that, you flip a switch and it energizes the other two retarders, so you’re running on four at once, but they all go through the same load cell. It just gives you the ability to hold back more power, which is nice.”

Moran told us the reason he went with a Mainline hub dyno was because in doing his research there wasn’t anyone else in the market with a closed-loop system.

“Everything out there was a lot like engine dynos,” he says. “You’ve got to take a guess at how much proportional and derivative gains it takes to grab a hold of a combination and sweep it. Whereas, the Mainline has an encoder built in and an algorithm that can take the rpm you want to start with and finish at and how fast you want to accelerate, and it just does it.

“On the engine dyno, you have what’s called overshoot and undershoot. It’s a fine line to take a guess at how much it takes to hold onto that thing and then rip it. On the hub dyno, you tell it A and B and how fast you want it to get from A to B and it does it. It’s really nice. It’s worth the investment. It’s more than three times more expensive than other units out there, but there’s a reason for it.”

One of the best features of the hub dyno, according to Moran, is that you can replicate a day at the track, so when it comes time to actually lay down a run, you’re already a step ahead.

“I don’t know if anybody else feels this way, but I just call that thing a drag strip simulator, because you actually make the same run you make at the track,” he says. “If your car runs 4.0s, I can program a 4.0 run and it just traces it. I just tell it how long I want it to take, the max rpm of the engine, the rpm curve I want to see, and I can replicate what you do at the drag strip.

“Customers tell me what their car runs and I’ll put it in as that. I’ll give it a starting point at the two step and then I’ll select an acceleration curve – 400 rpm a second – and at that point it’ll spit out how long it’ll take. Then, you just move that until they match. You can replicate exactly what’s going on at the drag strip and it’s such a valuable tool. You can bring your lockups in and out. You can watch your timers cascade. You can look at it on a graph and much more.

“Just the other day, when I ran a car that was going to the drag strip for the very first time, I looked at the curve and thought, this thing looks really hot out of the hole. I figured it was going to smoke the tires, so we just wrote a timing curve in there and you could literally lay the one power curve over the other and watch how 10 degrees affects it through low gear. That’s what you need so you can put your best foot forward at the drag strip. You don’t waste a bunch of time. It’s very, very informative.”

As Mike has mentioned, the features and potential benefits are clear. However, beyond the investment of a hub dyno, you’ll also need to consider the amount of space needed in the shop. According to Moran, his dyno required 30-feet of width, as well as extra room for the stacked absorbers. He built out an entire room to house his new set up, but not every hub dyno needs this much space. They do, however, require some considerable planning ahead of time, no matter the size.

“It’s a big planning situation and I can tell you that we had months involved in CAD and everything else, laying it out in the building, and what it would take for the fan requirements to change the air in there for alcohol combinations,” he says. “You definitely need proper planning.”

If you’re looking to up your game within your engine shop, an engine dyno and a hub dyno are two great ways to do it. One will make your engines better than they’ve ever been, while the other will dial in your customers cars for the track, and both will generate additional revenue for your shop. Now you just have to make it happen. EB