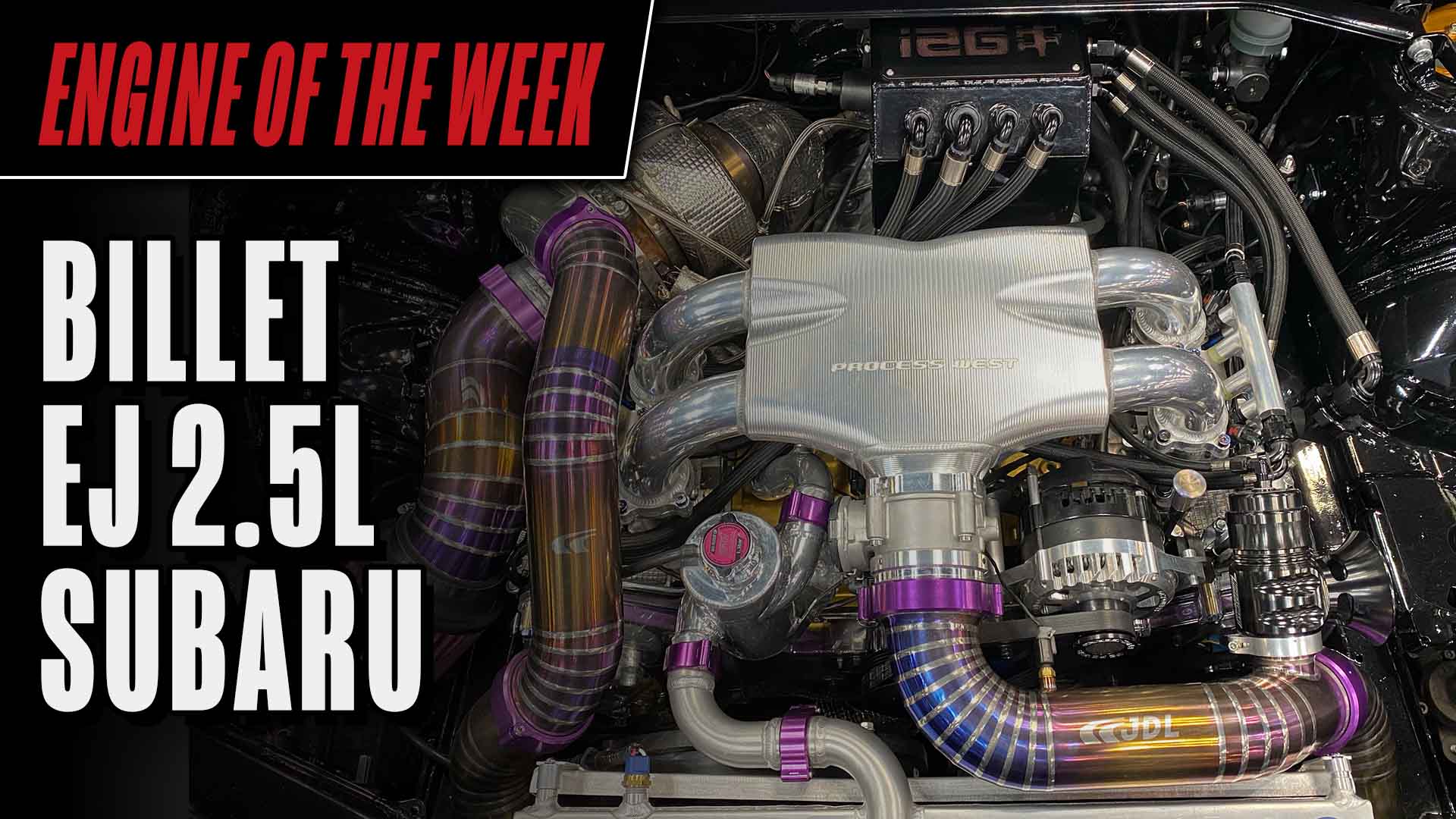

Legendary Japanese Tuning Platforms

When it comes to making high-performance horsepower with a Subaru engine, the breadwinner has always been the EJ family of engines. Consisting of a series of four-stroke engines first introduced in 1989, the EJ family succeeded the Subaru EA engine. The EJ series is the mainstay of Subaru’s engine line, with all engines of this series being 16-valve horizontal flat-fours with SOHC or DOHC arrangements. Naturally aspirated and turbocharged versions are available, ranging from 96 hp to 320 hp from the factory.

Of all the engines in the EJ series, two are clear standouts when it comes to rebuilding for performance applications – the EJ257 and EJ207. The U.S.-marketed STI featured the EJ257, while the EJ207 is considered the holy grail from Japan.

“Those two engines in the import world, even given some inherent design flaws with respect to their weaknesses, are still and always will remain legendary Japanese tuning platforms,” says Justin Anning of Nemesis Performance in Manitoba, Canada. “They both make easy power. They’re both well, well known. Those engines, even though they’re slowly getting phased out, I don’t think they’re going to be forgotten. They’ll always remain legendary in the Subaru world.”

Architecturally, the EJ257 and EJ207 are the same, but internally they have several differences. The biggest difference right off the bat is displacement.

“The U.S.-marketed STI is a 2.5L,” Anning says. “The 2.5L has an increased bore diameter from 92mm to 99.5mm as well as increased stroke from 75mm to 79mm. That’s how they got the extra torque. The EJ207, which is the Japanese or the JDM STI, although it’s smaller in displacement (2.0L), it packs more punch. It has a better turbocharger system – what we refer to as a twin scroll turbo. It’s got a way better flowing head and it’s got better cams throughout. There’s a lot more that went into the JDM stuff than went into the U.S. version. It’s also a more reliable motor being that it’s a fully forged unit, whereas the U.S. EJ is not.”

Another Subaru engine platform that has people excited is the OEM’s new flagship for performance called the FA. The FA20 released in 2015 in the WRX, specifically, has Subaru fans eager to see its potential when built up.

“It is a completely different design than the EJ, although it still remains an opposing four cylinder,” Anning says. “It has direct injection technology, mechanical fuel pump, asymmetrical connecting rods. It’s a very squared motor. It’s an 86mm bore and an 86mm stroke, whereas all the STIs are over square. Instead of shim-less buckets, it’s got rocker arms with hydraulic lash adjusters in it. It’s a neat little motor, but it’s fairly new and in the infancy of the program. Some people have pushed it pretty far, but nobody’s really well-versed in it like the EJ platform. It’s getting there, and now there’s talks of a release of a new STI with the FA24, which will be a 2.4L.”

With these three engines as the clear “cool kids” among the Subaru class, we spoke with Justin about each one and how he has seen these engines get built for performance applications.

EJ257

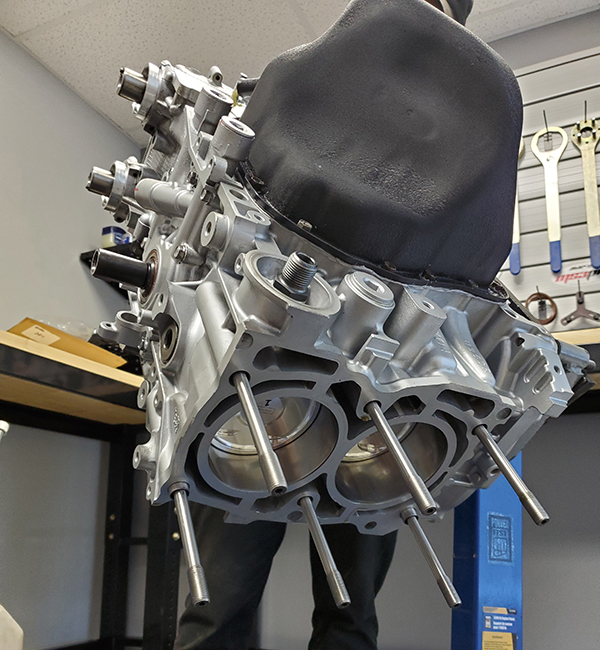

The EJ257, which is in the U.S.-marketed STI, comes with a factory forged crank and factory forged rods, but the pistons are not forged, which has led people to upgrade the engine due to failures. The rod bearings are also a weak point to watch.

“Typically, what happens is they’re consuming a lot of oil because they’ve cracked a ring land on the piston,” Anning says. “The vehicle still runs fairly well, especially when the turbocharger comes online, it creates enough compression that you don’t really notice it, but at idle you can tell that it’s hurt.

“We always tend to look at the pistons right away as well as the rod bearings. They tend to be a failure point. They end up spinning rod bearings quite often.”

When EJ257s come into Nemesis Performance, the shop completely strips them down and blueprints them for proper oil clearances in performance-minded applications.

“They’re outfitted with a fresh set of new connecting rods if the build has a horsepower output higher than what the factory rod is capable of,” he says. “One hundred percent of the time we’re doing pistons no matter what, because that is the next weak point. If you didn’t spin a rod bearing, you’re going to crack a ring land.”

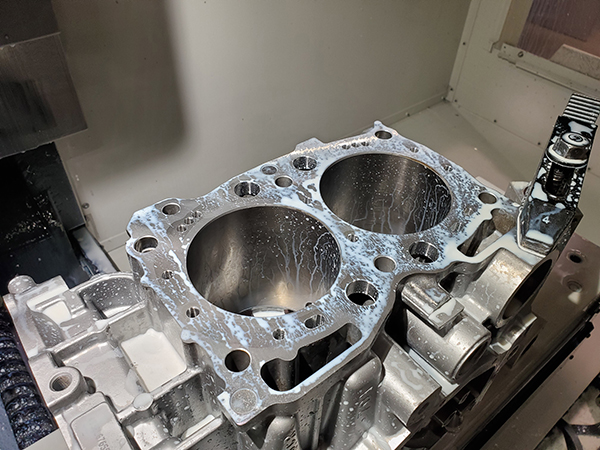

Most of the time, customers are building up the EJ257 for street car, drag racing or road racing applications, and if customers want to find a lot of power, Nemesis Performance addresses an inherent weakness in the structure of the cylinder blocks.

“We put it on our Haas CNC and we actually machine what is called a closed-deck block,” he says. “Basically, the cylinders and what supports them in the block is only held together by four little tabs. As boost increases and horsepower increases along with the harmonics that come with horsepower, they will actually crack the cylinder liner. That block now needs to be repaired and needs sleeves.

“We’ve adopted the philosophy of scanning the block into a CAD. We’ve designed these inserts that get machined. The block gets machined and the inserts get pressed in and effectively close the upper deck of the block and supports the cylinder structure right where it’s required, which is usually right where all the combustion force is happening in the first half-inch of the block.

“Not only does it create a more robust engine, but you have a significantly increased clamping surface for the head gasket, which is another inherent problem of Subarus too. You’re getting the best of both worlds. You’ve got more surface area to clamp the head gasket and keep its integrity intact, as well as keeping the rigidity and supporting the cylinders from moving and cracking.”

Anning suggests that if a customer desires to go north of 500 horsepower or in excess of 30-lbs. of boost, a closed-deck block is a requirement for added protection.

“That’s not to say you can’t do it without this modification, but you’re really pushing the limits of everything at that level,” he admits. “The upgrades we look at performing are in oiling, hypereutectic pistons instead of forged and the deck architecture of the block itself.”

The 2.5L EJ257 can make 300-400 horsepower in stock trim with some simple bolt-ons. But, when you start getting into quite substantially larger turbocharger systems, Anning has personally built cars in the 800-horsepower range and above.

“Commonly though, that’s just not for everybody, as you can imagine the type of maintenance that comes with that type of horsepower,” he says. “Most of those builds are around the 500-650 horsepower mark for the 2.5L.”

EJ207

Across the pond in Japan, the EJ207 can handle quite a bit more power due to the fact that the cylinder liners are much thicker. Compared to the U.S. EJ257 with a 99.5mm bore diameter that’s been bored through the casting, this is now a 92mm bore, so the thickness of the cylinder liners is substantial, which also aides in the clamping surface area of the head gasket.

“We don’t actually see a lot of those engines,” Anning says. “When those vehicles do show up at our shop, it’s more so for tuning for North American gas or the addition of parts. A couple of the builds that we do for some of these guys that have the 207 is we will build a stroker motor, which brings it up to a 2.2L. It makes a substantial difference in the drivability of it.”

According to Anning, the EJ207 flows really well and redlines around 8,000 rpm from the factory versus a North American STI, which you can feel fall off around 5,500 rpm.

“From a driving standpoint, a North American Subaru will really come online in the mid range, but then start to choke up top,” he says. “That’s because of the physical size of the engine. It’s ingesting more air than what the turbo can do. In our opinion, the turbocharger is not suitable for higher rpm sustainability to maintain that boost pressure.

“Whereas, when you go to the EJ207, right off the bat, the engine is a smaller displacement, so it’s moving less air. Boost is a function of back pressure, so the turbocharger can actually stay online longer because the motor is not ingesting as much air per revolution. The driving experience in the 207 doesn’t hit you hard in the mid range like a North American does, but the power comes on at a more linear fashion and it just pulls harder and pulls a lot longer in the revs.”

The EJ207 comes with a dual ball bearing turbocharger, and in some specific years, they also address mid-end torque with a twin scroll turbocharger system. That twin scroll helps with spool and it helps with top end power as well, giving you the best of both worlds.

“The 207 is better suited for road racing applications since the power is more manageable and linear, and it also has a broader power range, even though it is down on displacement,” Anning says. “It just pulls for a lot longer because the maximum rpm is 8,500 and you can feel the power even at 7,000-7,500 rpm – it just wants to keep playing up there, which is nice for road racing. It works well for that.

“The 207 comes advertised at about 285 horsepower from Japan. They typically run anywhere, with just simple bolt-ons, in the 300-325 wheel horsepower range. With more boost and bolt-ons you can get 350-400 wheel horsepower, depending on what type of fuel you’re running. Most of the builds in the 2.0L range are in that 400 wheel horsepower when they’re fully built with a larger turbocharger system and supporting fueling mods. That’s a comfortable pump gas range for those vehicles.”

FA20

The FA engine is a completely different animal, even though it’s still a horizontally opposing four-cylinder. Currently, the 2.0L is in the WRX and the 2.4L is in the Ascent.

“These FA motors are just wildly different than an EJ, even though on the surface they may appear the same,” Anning says. “They have a cam cradle rather than cams just sitting in the head. There’s an actual bolted cradle system that drops the cams in as well as a lower girdle on the block. All of the things that seem to be an issue with the EJ life seems to be addressed with the FA.”

The initial design of the FA was for an application that had a lot of bottom-end torque. These engines came equipped with a standard Garrett Honeywell twin scroll turbocharger versus an IHI turbocharger in the EJ platform.

“From a tuning standpoint, the engine’s electronics come outfitted with factory fuel pressure monitors, factory oil pressure monitors, a Bosch wide band, and an exhaust gas temperature analyzer in it,” he says. “From a tuning standpoint they’re extremely, extremely friendly for the tuners as far as data displayed and information that can be displayed to the tuner during the tuning process. Those are big bonuses.

“In the engine itself, I was not a big fan of the asymmetrical connecting rods. Just by looking at them on the surface, I always felt asymmetrical rods can’t be as strong. The reason they did that was to be able to stuff such as a large stroke in such a small package. They had to make clearance for it. Rather than grow the engine to make up for the extra stroke, they decided to offset the connecting rods to make room for it. What the result was with that greater stroke is that the torque is substantial.

“An STI is 79mm stroke and the FA is an 86mm stroke – that’s a big difference. Combine that with a twin scroll turbo, which is designed to give you major low-end response, you have a pretty strong package.”

While there is palpable excitement surrounding the FA engine and what could be, most shops haven’t seen much of it from a rebuild standpoint… yet.

“We haven’t seen a lot of FAs in here because the brutal reality and the honest truth is they just don’t blow up as much,” he says. “They’re relatively new enough that they’re still being covered by Subaru’s warranties too. Now that we’re in 2020 and the FA came out in 2015, everything is going to start coming off warranty. Once it’s off warranty and you have some trouble, you’re not going to rebuild it stock, you’re probably going to build it better.”

On top of Subaru builders’ excitement for the 2.0L FA, rumor has it that the 2.4L FA is slated for the STI, which could produce some nice horsepower numbers.

“A Stage 2 tuned WRX, which houses the FA, versus a Stage 2 tuned EJ STI has almost identical power output,” he says. “You’re spending less money on the WRX and with very little mods you’re putting out around the same amount of horsepower that the STI is. A strong Stage 2 WRX on pump gas is looking at 300 wheel horsepower. That’s quite a rocket ship you’ve got there from the standpoint of all you’ve really done was put intake and exhaust on it and tuned it. Those are some pretty good gains and pretty good numbers.”

As Anning said, Subaru engines continue to be top Japanese tuning platforms, and it doesn’t appear that will end any time soon! EB